Floating oil seal outer bevel automatic processing lathe

An automatic processing and floating oil seal technology, which is applied in metal processing equipment, grinding machine parts, grinding automatic control devices, etc., can solve the problems of high energy consumption and low production quality of floating oil seals, so as to protect the environment and improve products The pass rate and product quality, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

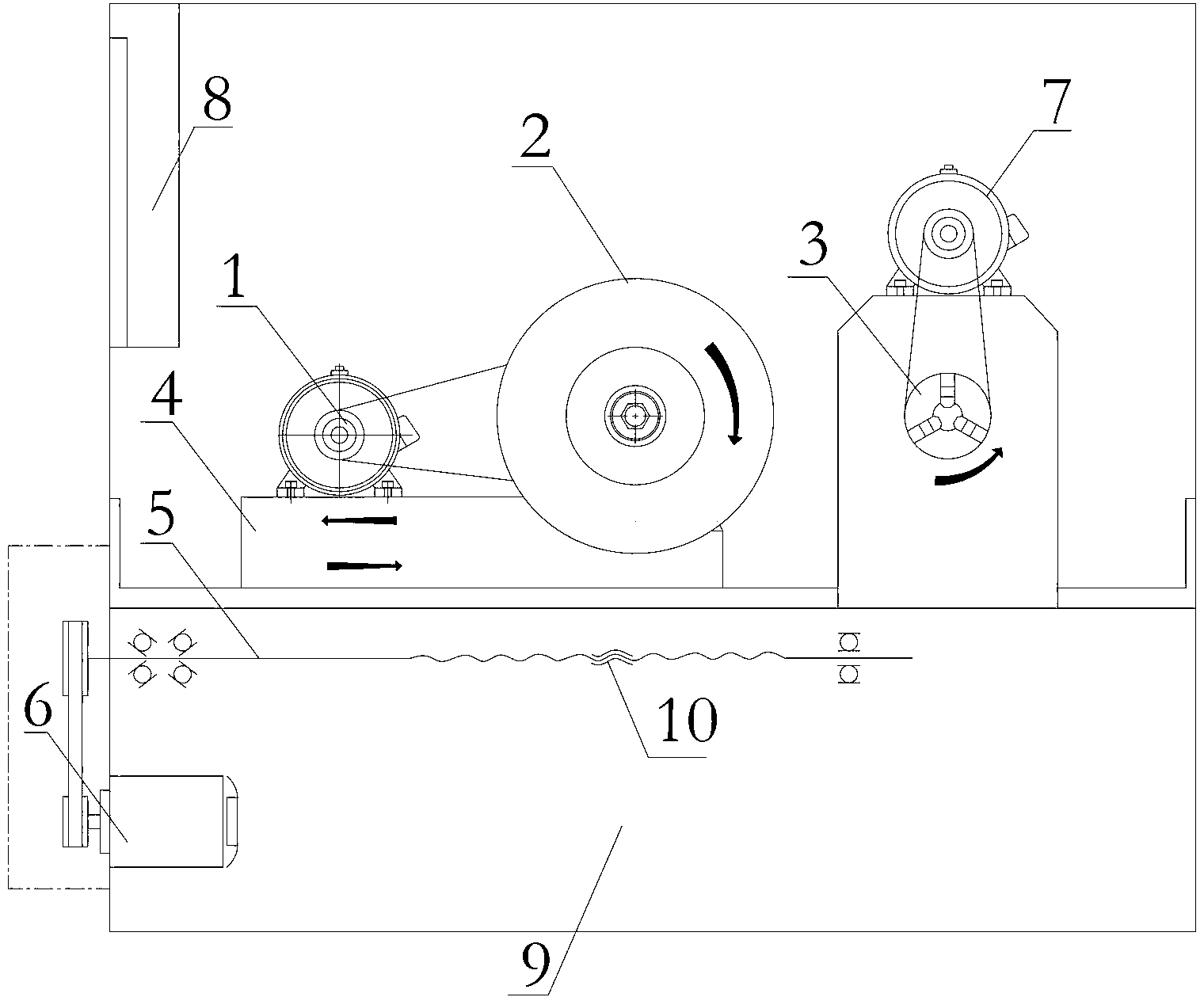

[0020] Such as figure 1 As shown, it is an embodiment of the automatic processing machine tool for the outer slope of the floating oil seal of the present invention, which can change the traditional processing technology of "blank annealing-NC turning processing-quenching", and save "blank annealing" and "NC turning Processing" processing step, directly quench the workpiece, and then use the machine tool to process, so as to realize the automatic processing of the floating oil seal, greatly shorten the production cycle of the floating oil seal, and improve the product qualification rate and product quality.

[0021] The automatic processing machine tool firstly includes a bed 9 on which a clamping mechanism, a grinding mechanism and a feeding mechanism are respectively arranged. Among them, the function of the clamping mechanism is to clamp the workpiece and drive the workpiece to rotate, the function of the grinding mechanism is to directly grind the workpiece, and the rotati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap