Numerical control full-automatic machine tool special for cams

A processing machine tool, fully automatic technology, applied in the direction of grinding frame, grinding bed, abrasive belt grinder, etc., can solve the problems of intermittent running track, high production cost, and low control accuracy, and achieve room for adjustment Large, low production cost, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

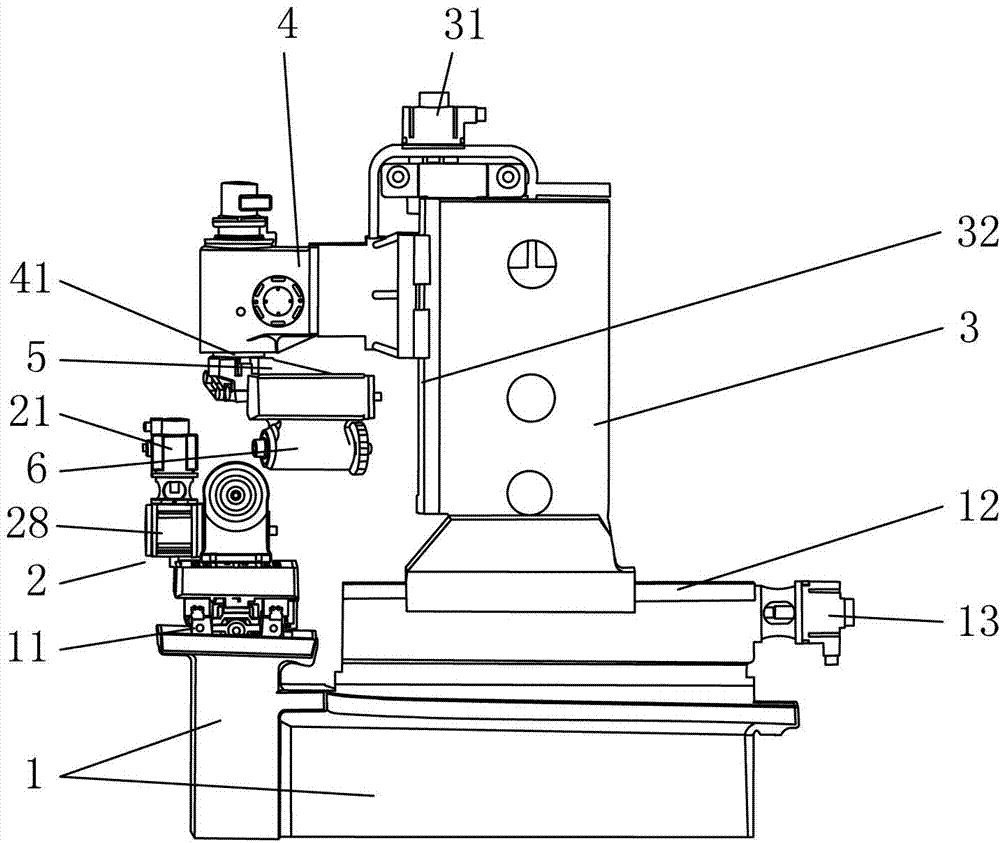

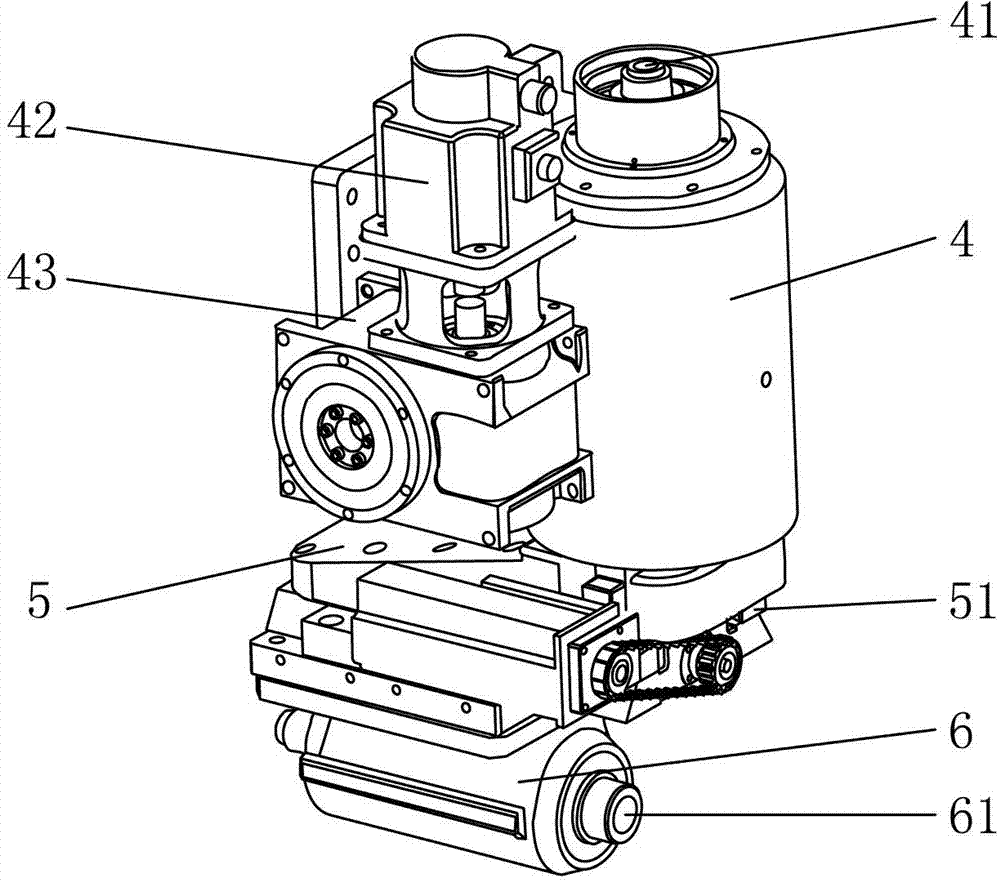

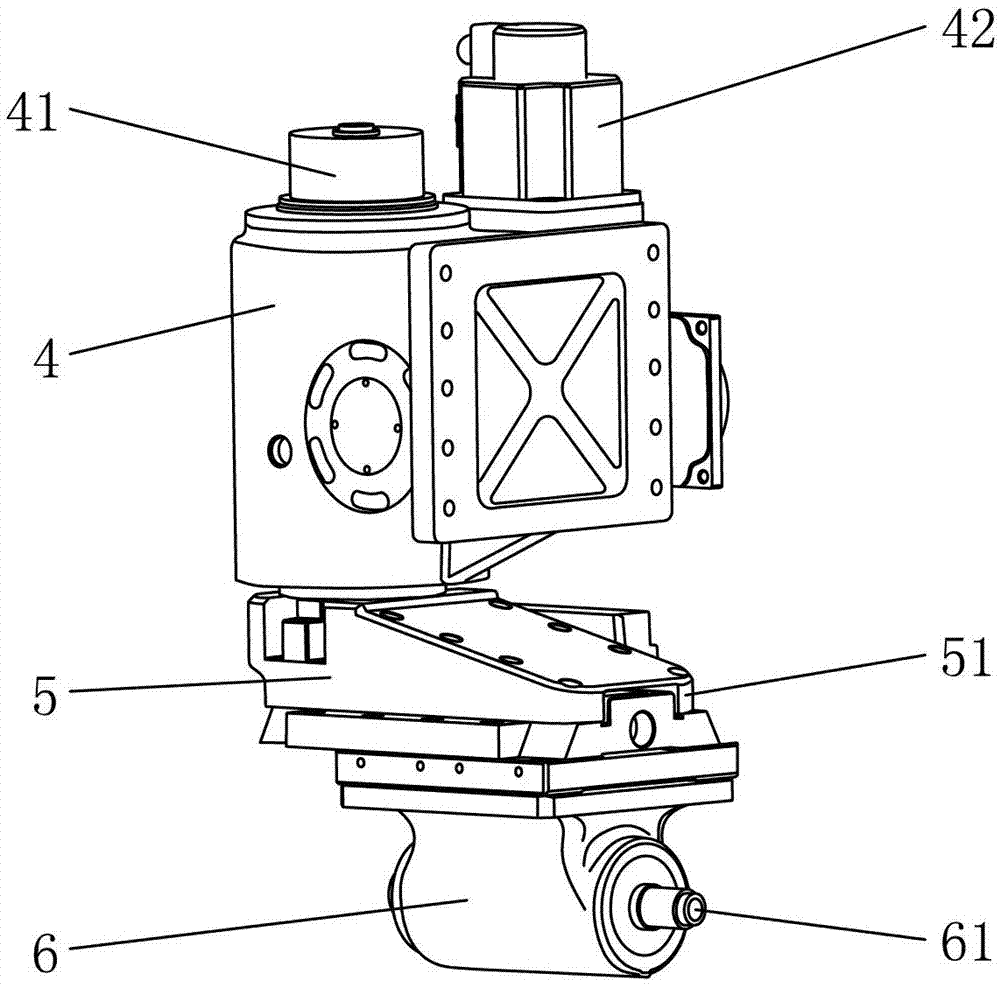

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 5 :

[0024] CNC full-automatic cam processing machine tool, including organic base 1, on the transverse guide rail 11 set on the front side of the base 1, there is a worktable that can move laterally along the transverse guide rail 11, on the worktable is installed a T-shaped The longitudinal guide rail 12 that groove moves, the longitudinal guide rail 12 that the rear side is provided with is provided with the machine head frame 3 that motor 13 drives can move longitudinally along longitudinal guide rail 12, and the vertical guide rail 32 that head frame 3 front side is provided with is provided with motor 31 drives the headstock 4 that can move up and down along the vertical guide rail 32, the lower side of the vertical shaft 41 driven by the motor that is vertically arranged on the front side of the headstock 4 is fixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com