Complexing-agent-assisted preparation method of cadmium sulfide multi-level-structured nano-grade material

A technology of nanomaterials and cadmium sulfide, which is applied in the field of preparation of nanomaterials to achieve the effect of satisfying production and application, strong operability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] ①In a 50 ml flask, add 1 part of cadmium acetate and 10 parts of trisodium citrate to 100 parts of water, heat to 60°C and keep it for 30 minutes, stir well to prepare a reaction solution.

[0030] ②Transfer the reaction solution prepared according to step ① into a high-pressure reactor with a 25 ml polytetrafluoroethylene liner, add thiourea (the molar ratio to cadmium acetate is 1:1), and react at 160°C for 24 hours , the reaction kettle was naturally cooled to about 60°C, 5 ml of methanol was added, the product was filtered, washed several times with absolute ethanol, and the sample was vacuum-dried to obtain cadmium sulfide hierarchical structure nanomaterials with regular size and shape.

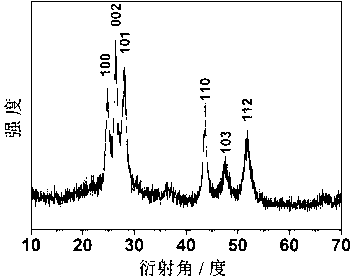

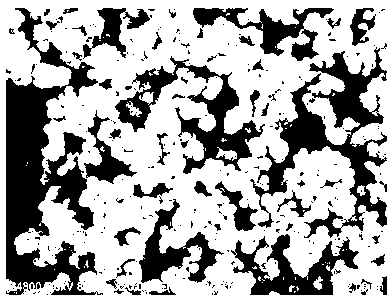

[0031] figure 1 and figure 2 Respectively, the X-ray diffraction pattern and the scanning electron micrograph of the prepared cadmium sulfide hierarchical structure nanomaterial. From the X-ray diffraction pattern ( figure 1 ) It can be seen that cadmium sulfide has a hexagon...

Embodiment 2

[0033] ①In a 50 ml flask, add 1 part of cadmium acetate to 100 parts of water, heat to 30 ℃ and keep it for 30 minutes, stir well to prepare the reaction solution.

[0034] ②Transfer the reaction solution prepared according to step ① into a high-pressure reactor with a 25 ml polytetrafluoroethylene liner, add thiourea (the molar ratio to cadmium acetate is 10:1), and react at 140 °C for 24 hours , the reaction kettle was naturally cooled to about 60°C, 5 ml of methanol was added, the product was filtered, washed several times with absolute ethanol, and the sample was vacuum-dried to obtain a cadmium sulfide hierarchical structure nanomaterial.

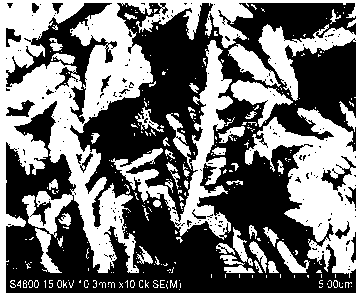

[0035] image 3 It is the scanning electron micrograph of the prepared cadmium sulfide hierarchical structure nanomaterial. It can be seen from the figure that cadmium sulfide has a dendritic structure.

Embodiment 3

[0037] ①In a 50 ml flask, add 1 part of cadmium nitrate and 20 parts of citric acid to 100 parts of water / ethanol mixture, heat to 30 ℃ and keep it for 30 minutes, stir well to prepare a reaction solution.

[0038] ② Transfer the reaction solution prepared according to step ① into a high-pressure reactor with a 25 ml polytetrafluoroethylene liner, add thioacetamide (the molar ratio to cadmium nitrate is 2:1), and react at 200 °C for 6 Hours later, the reactor was naturally cooled to about 60 °C, 5 ml of methanol was added, the product was filtered, washed several times with absolute ethanol, and the sample was vacuum-dried to obtain a cadmium sulfide hierarchical structure nanomaterial with regular size and shape .

[0039] Figure 4 and Figure 5 Respectively, the X-ray diffraction pattern and the scanning electron micrograph of the prepared cadmium sulfide hierarchical structure nanomaterial. From the X-ray diffraction pattern ( Figure 4 ) It can be seen that cadmium su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com