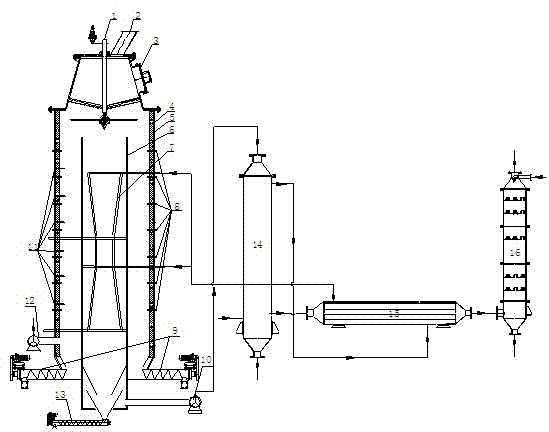

Equipment and technology for producing synthesis gas through cooperating outer cylinder air gasification with inner cylinder steam gasification

An air gasification and water vapor technology, which is applied in the petroleum industry and the manufacture of combustible gases, etc., can solve the problems of wasting water, high tar content, and tar black water pollution, and achieve the effect of increasing the calorific value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018]Using Ф8-30mm biomass particles as raw materials, firstly through the feeding port and the homogenizing device, the material is evenly filled to 1 / 3 of the height of the outer cylinder, then the blower is turned on, and the air is evenly distributed to the outside through the air distribution port In the cylinder, use inflammables to ignite the material in the outer cylinder, and then control the amount of air supplied according to the temperature display of the temperature measuring device, so that the temperature rise rate of the outer cylinder is 90-100°C / h, and at the same time, continuously spread in the outer cylinder When the temperature of the outer cylinder reaches 900°C, increase the material layer height of the outer cylinder to 3 / 4. At this time, the induced draft fan of the outer cylinder must be turned on, and the temperature of the outer cylinder must be kept above 900°C by controlling the air intake. Then continue to feed until the inner and outer cylinder...

Embodiment 2

[0020] Using wood chips with a length, width and thickness of 40×20×8mm as the raw material, the material is evenly filled to 1 / 3 of the height of the outer cylinder through the feeding port and the homogenizing device, then the blower is turned on, and the air is evenly distributed through the air distribution port. Distribute it into the outer cylinder, then ignite the material in the outer cylinder with combustibles, and then control the amount of air supplied according to the temperature display of the temperature measuring device, so that the temperature rise rate of the outer cylinder is 90-100°C / h. Lay materials in the outer cylinder until the temperature of the outer cylinder reaches 900°C, then increase the material layer height of the outer cylinder to 3 / 4. At this time, the induced draft fan of the outer cylinder must be turned on, and the temperature of the outer cylinder must be maintained at Above 900°C, continue to feed until the inner and outer cylinders are ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com