Method for producing microalgae by utilizing industrial waste water and waste gas of biobutanol, and application of method

A bio-butanol and industrial wastewater technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of not comprehensively utilizing butanol waste liquid, achieve good economic benefits, prevent environmental pollution, and reduce costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

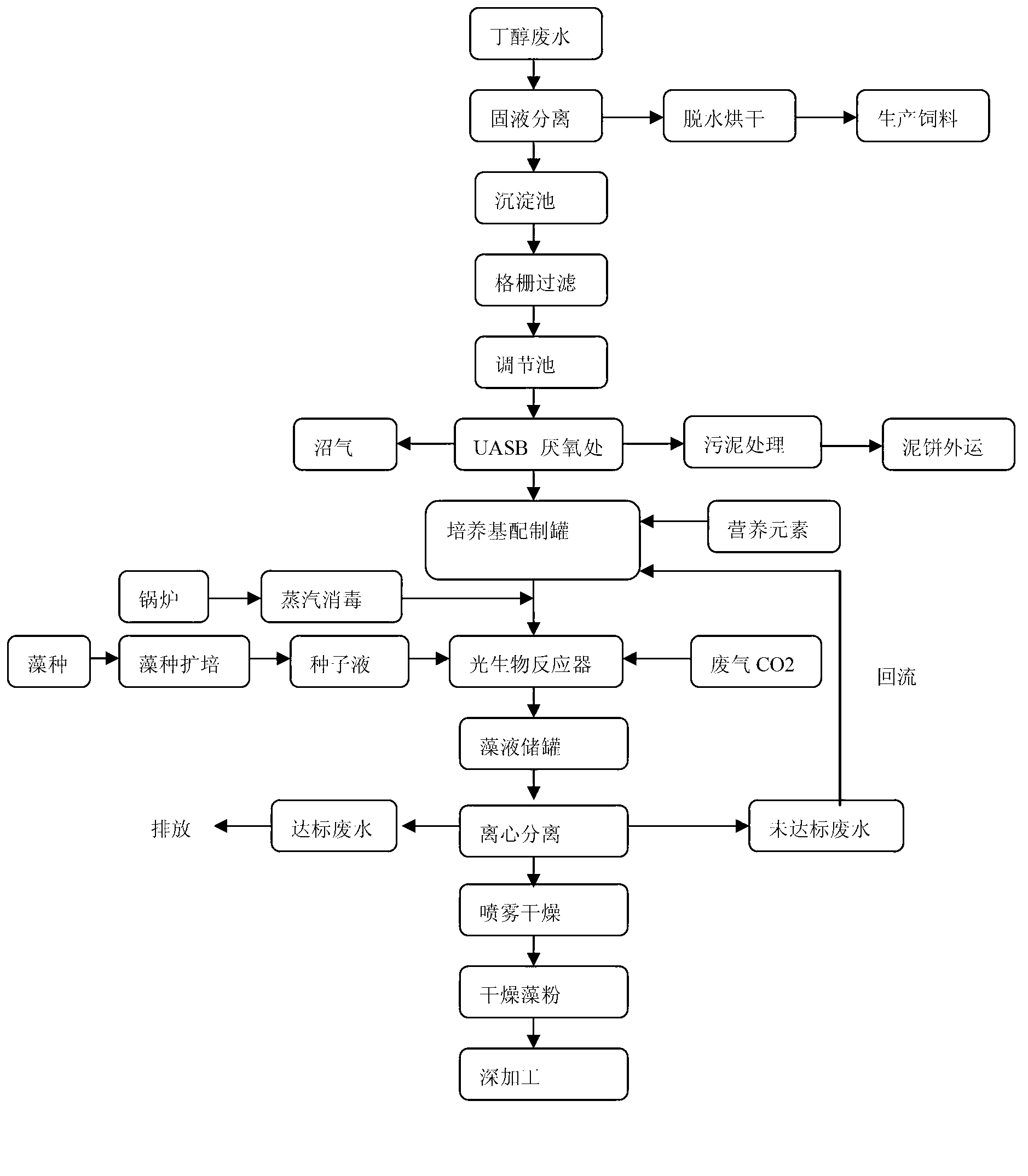

Image

Examples

Embodiment 1

[0046] Example 1 (Chlorella zofingiensis):

[0047] (1) Pretreatment of bio-butanol industrial wastewater: A factory with an annual output of 5,000 tons of bio-butanol, which uses corn as the main raw material, produces about 225,000 tons of wastewater per year, and its original bio-butanol industrial wastewater water quality index is CODcr37550mg / L , BOD20700mg / L, PO 4 3- P250mg / L, NO 3 - N200mg / L, NH 4 + -N100mg / L, ss5000mg / L, pH4.2; the water quality indicators of wastewater after sedimentation, filtration and anaerobic treatment are CODcr7400mg / L, BOD4500mg / L, PO 4 3- P150mg / L, NO 3 - N100mg / L, NH 4 + -N50mg / L, ss300mg / L, pH6.8;

[0048] The bio-butanol industrial wastewater is separated by a solid-liquid separator to obtain solids and liquids. The solids are dried and used to produce protein feed, and the liquids are placed in a sedimentation tank. After the impurities in it are precipitated, the suspended impurities are filtered through a grid The filtrate is...

Embodiment 2

[0055] Example 2 (Spirulina platensis):

[0056] (1) Pretreatment of bio-butanol industrial wastewater: A factory with an annual output of 5,000 tons of bio-butanol, which uses corn as the main raw material, produces about 225,000 tons of wastewater per year, and its original bio-butanol industrial wastewater water quality index is CODcr37550mg / L , BOD20700mg / L, PO 4 3- P250mg / L, NO 3 - N200mg / L, NH 4 + -N100mg / L, ss5000mg / L, pH4.2; the water quality indicators of wastewater after sedimentation, filtration and anaerobic treatment are CODcr7400mg / L, BOD4500mg / L, PO 4 3- P150mg / L, NO 3 - N100mg / L, NH 4 + -N50mg / L, ss300mg / L, pH6.8;

[0057]The bio-butanol industrial wastewater is separated by a solid-liquid separator to obtain solids and liquids. The solids are dried and used to produce protein feed, and the liquids are placed in a sedimentation tank. After the impurities in it are precipitated, the suspended impurities are filtered through a grid The filtrate is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com