Method for improving urban organic garbage mixed anaerobic digestion directional hydrolytic acidification effect

An anaerobic digestion, hydrolysis and acidification technology, applied in the direction of fermentation, etc., can solve the problems of low anaerobic digestion efficiency and easy corruption, and achieve the effect of reducing investment, improving conversion degree, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

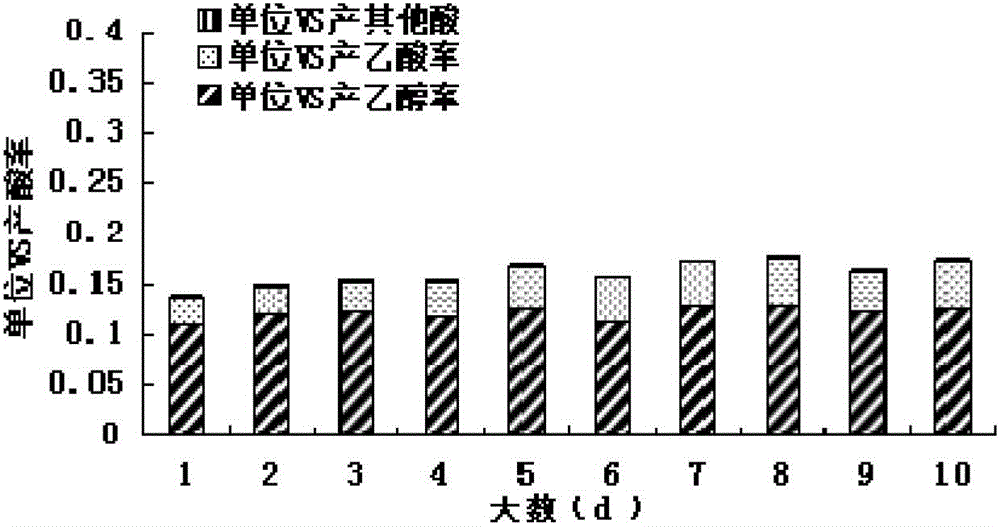

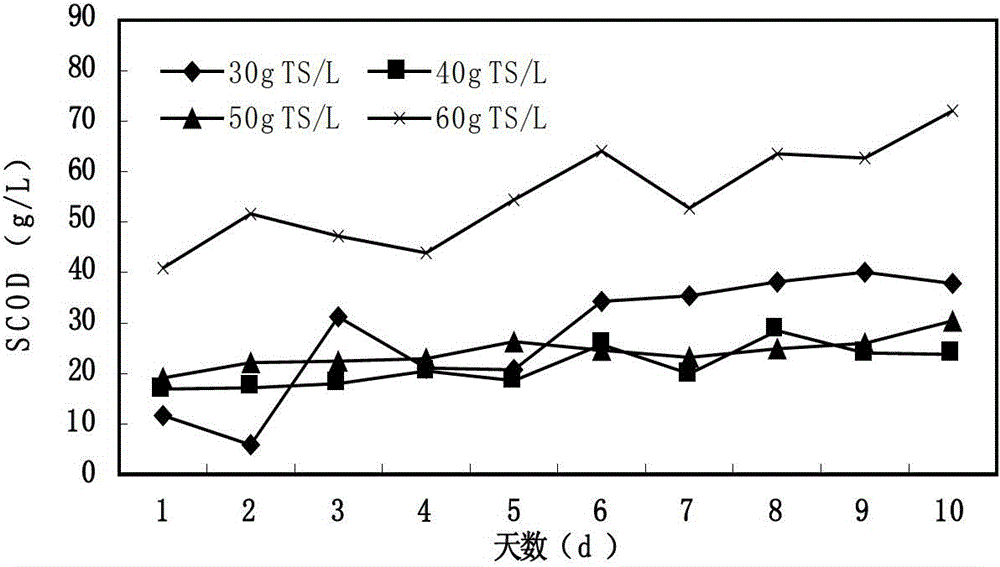

[0037] Mix the crushed kitchen and fruits and vegetables evenly according to the VS ratio of 3:1. The TS of food waste is 22.40%, VS is 20.07%, the TS of fruit and vegetable waste is 13.32%, and VS is 9.95%. The load is set to 30g TS / L means that the feeding load is 25.8gVS / L, and then remove the supernatant from the anaerobic digestion sludge that has settled for 7 days, the pH value is 8.23, the ammonia nitrogen value is 496mg / L, and the solid content of the supernatant is removed after sedimentation The TS is 7.86%, and the concentrated anaerobic digested sludge obtained by centrifuging at 4000r / min for 5 minutes has a solid content of TS of 12.46%, VS of 6.14%, and the inoculation amount of F / M=4:1 by VS Inoculation was performed with an initial pH of 6.20.

[0038] The above experiment was done in 10 parallels, and the effective working volume of the anaerobic digestion reactor was fixed to 500mL with tap water, the feed inlet was closed, a gas metering device was connec...

Embodiment 2

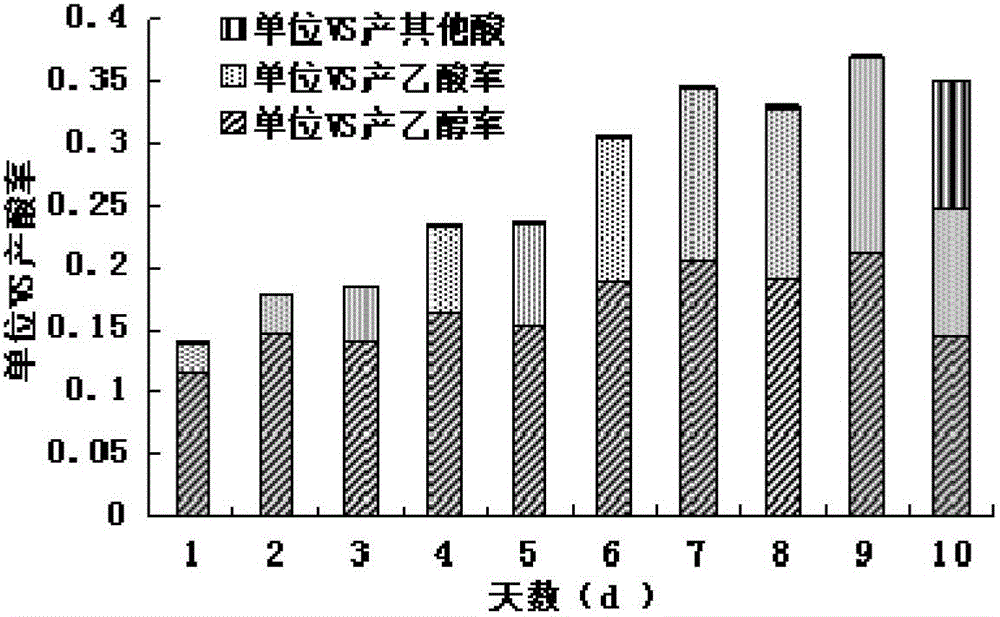

[0045] Mix the crushed kitchen and fruits and vegetables evenly according to the VS ratio of 3:1. The TS of food waste is 20.38%, VS is 18.26%, the TS of fruit and vegetable waste is 11.67%, and VS is 8.72%. The load is set to 60g TS / L means that the feeding load is 51.6gVS / L, and then remove the supernatant from the anaerobic digestion sludge that has settled for 7 days, the pH value is 7.12, and the ammonia nitrogen value is 216mg / L, and the solid content of the supernatant is removed after sedimentation The TS is 5.64%, and the concentrated anaerobic digestion inoculum can be obtained by centrifuging at 4000r / min for 5 minutes. The solid content of TS reaches 11.21%, VS reaches 5.47%, and the inoculum is calculated by VS with F / M=4:1 The amount of inoculation was carried out, and the initial pH value was 4.62.

[0046] The above experiment was done in 10 parallels, and the effective working volume of the anaerobic digestion reactor was fixed to 500mL with tap water, the fe...

Embodiment 3

[0053] Mix the crushed kitchen and fruits and vegetables evenly according to the VS ratio of 3:1. The TS of kitchen waste is 16.80%, VS is 15.05%, the TS of fruit and vegetable waste is 9.62%, and VS is 7.22%. The load is set to 50g TS / L means that the feeding load is 43.0gVS / L, and then remove the supernatant from the anaerobic digestion sludge that has settled for 7 days, the pH value is 7.56, the ammonia nitrogen value is 313mg / L, and the solid content of the supernatant is removed after sedimentation TS is 6.53%, and it can be centrifuged at 4000r / min for 5 minutes to obtain concentrated anaerobic digestion inoculum. The solid content of TS reaches 11.28%, VS reaches 5.65%, and the inoculum is calculated by VS with F / M=4:1 The amount of inoculation was carried out, and the initial pH value was 5.56.

[0054] The above experiments were performed in 10 parallels, and the effective working volume of the anaerobic digestion reactor was fixed to 500mL with tap water, the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com