Intelligent transmitting device for essential safety of slag stopping balls in converter

A converter slag blocking and launching device technology, applied in the direction of manufacturing converters, etc., can solve the problems of easy slump, increased furnace repair frequency, endangering the life safety of throwing personnel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

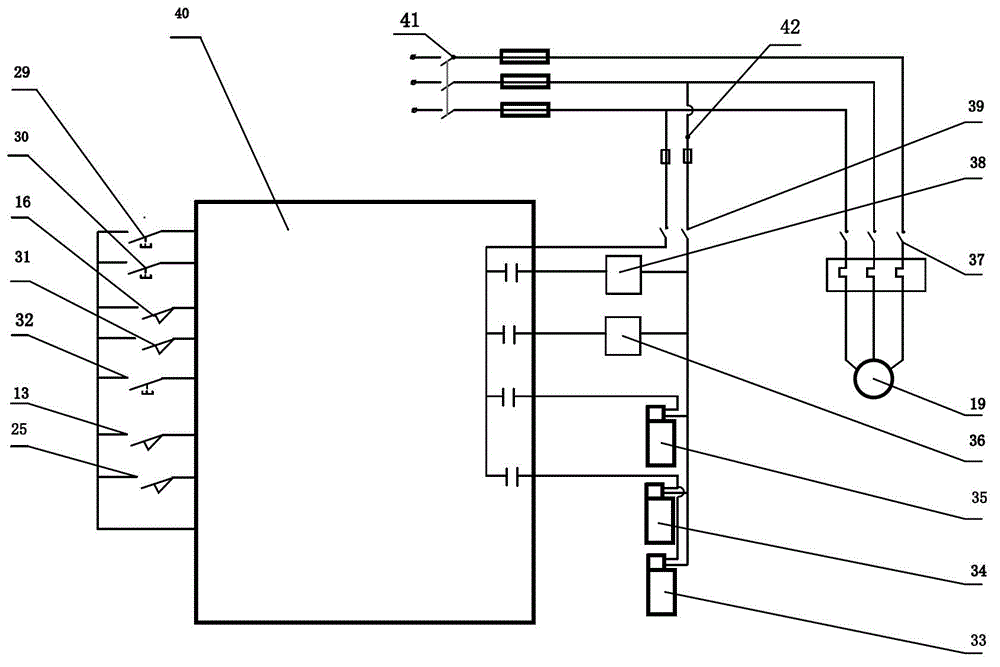

[0010] Such as figure 1 As shown, it includes: PLC control system (40) and the input terminal of PLC control system (40) is connected with: system start switch (29), system stop switch (30), motor start switch (16), temperature acquisition switch (31 ), manual launch switch (32), lock start switch (13), toggle switch (25); the output terminals of the PLC control system (40) are connected with: left toggle solenoid valve (33), right toggle solenoid valve ( 34), trigger solenoid valve (35), motor relay coil (36), intermediate relay coil (38), and motor relay contact (37), motor (19), main power supply ( 41) is also connected with a control power supply (42), and the control power supply (42) is connected with an intermediate relay contact (39).

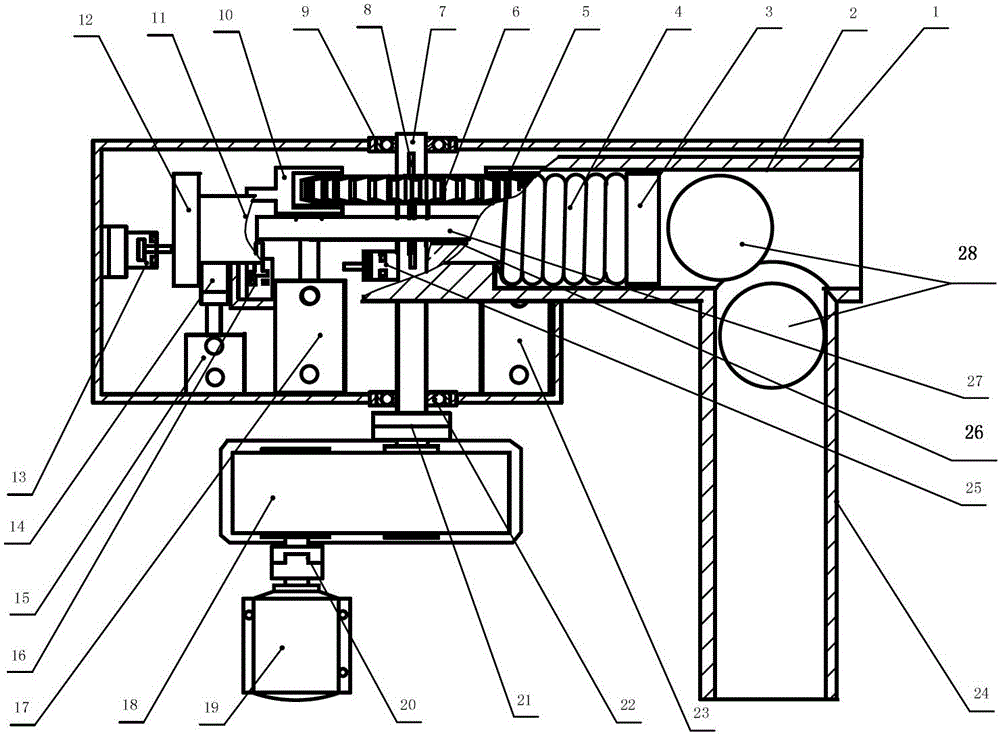

[0011] Such as figure 2 As shown, in the housing (1) of the main equipment, the housing (1) is provided with a launch tube (2). The diameter of the launch tube (2) is smaller than that of the right section, and there is an open slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com