Multi-junction solar battery and preparation method thereof

A technology of solar cells and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as lattice mismatch, achieve the effect of reducing dislocation density and broadening the spectral absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

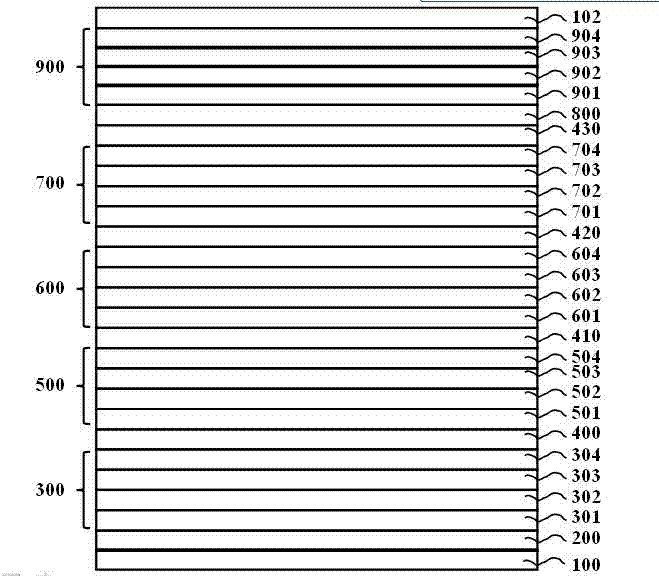

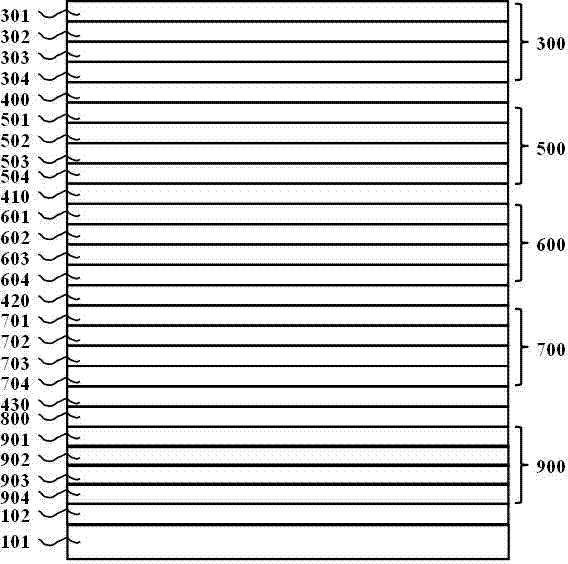

[0055] This embodiment discloses a flip-chip five-junction solar cell, and its structure will be specifically described below in conjunction with a growth method.

[0056] First, in the MOCVD system, a p-type GaAs substrate 100 is selected, and its doping concentration is 2×10 17 cm -3 -- 5×10 17 cm -3 ; Epitaxial growth of GaInP on the surface of the substrate etch the cut-off layer 200, its thickness is 150 nm, and the doping is about 1×10 18 cm -3 .

[0057]In the next step, the AlGaInP first sub-cell 300 is flip-chip grown on the etching cut-off layer 200, and its band gap is 2.2 eV, specifically including: n-type AlGaInP window layer 301, its thickness is 25 nm, and the doping concentration is 1×10 18 cm -3 around; the thickness of the emitting region 302 is 150 nm, and the doping concentration is 2×10 18 cm -3 ; The preferred thickness of the base region 303 is 900 nm, and the doping concentration is 5×10 17 cm -3 ; The p-type AlGaInP back field layer 304 has ...

Embodiment 2

[0071] This embodiment discloses a flip-chip four-junction solar cell. On the basis of Implementation 1, the first AlGaInP sub-cell 300 can be removed, and the second GaInP sub-cell 500 can be used as the first sub-cell of this embodiment to form a 1.89 eV / 1.65 eV / 1.4 eV / 1 eV flip-chip four-junction solar cells.

Embodiment 3

[0073] This embodiment discloses a flip-chip four-junction solar cell, and the GaInP second sub-cell 500 can be removed on the basis of implementation one to form a 2.2 eV / 1.65 eV / 1.4 eV / 1 eV flip-chip four-junction solar cell.

PUM

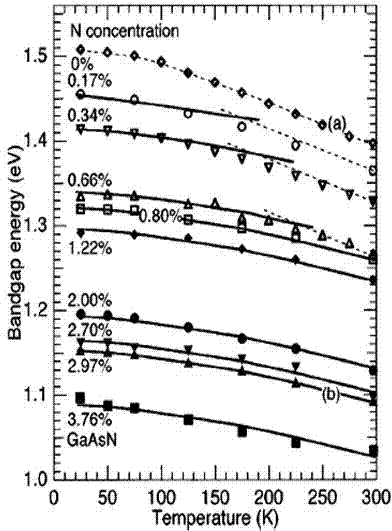

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com