Coating agent for pharmaceutical solid preparation, pharmaceutical film formulation, and coated pharmaceutical solid preparation

A technology for solid preparations and coating agents, which is applied in the fields of coating agents for pharmaceutical solid preparations, film preparations for pharmaceuticals and coating solid pharmaceutical preparations, can solve problems such as bad odor and discoloration of medicines, and can prevent deterioration and provide excellent gas barrier properties. Excellent performance and disintegrability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0110] Add 10.5 parts by mass of PEG (Macrogel 6000 (average molecular weight 7300 to 9300); NOF), 544.4 parts by mass of 4.5% BT solution and 3.5 parts by mass of Span20 in 445.1 parts by mass of water, and pass through a homogenizer (Polytonon (registered trademark) Model KR) was stirred to obtain a coating agent (hereinafter referred to as "Example 1 coating agent"). It should be noted that, as a 4.5% BT solution, the following solution was used: 45 parts by mass of BT (クニピア-F (cation exchange capacity: 115meq / 100g); Kunimine Industry) was added to 955 parts by mass of stirred water, and the solution was passed through homogenization. The filtrate was obtained by centrifugal separation after the homogeneous dispersion in the dehumidifier, and the supernatant was suction-filtered with filter paper.

[0111] 50g of sodium valproate tablets (デパケン (registered trademark) tablets 200mg; Kyowa Hakko Kirin Corporation) and 200g of blank control tablets ( ) (for increasing the vol...

Embodiment 2)

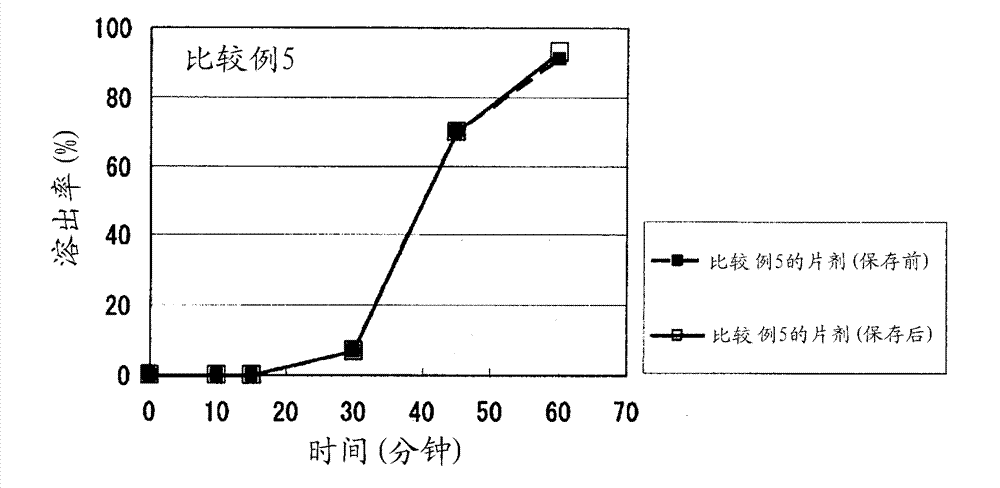

[0114] Add 20g of montelukast sodium tablets (Singley (registered trademark) tablets 10mg; Wanwu Pharmaceutical) and 230g of blank control tablets (for increasing volume) into a coating pan (DRC-200; Example 1 The coating agent coated montelukast sodium tablets until the thickness of the film reached 60-80 μm. The thus-obtained coated montelukast sodium tablets were stored at 40° C. and a relative humidity of 75% for one week, and the dissolution profile and moisture absorption increase before and after storage were studied.

Embodiment 3)

[0116] Add 5.25 parts by mass of PEG (Macrogol 6000; NOF) and 382.8 parts by mass of 3.2% BT solution to 111.95 parts by mass of water, and stir with a homogenizer to obtain a coating agent (hereinafter referred to as "Example 3 coating agent"). It should be noted that, as the 3.2% BT solution, the following solution was used: 32 parts by mass of BT (クニピア-F; Kunimine Industry) was added to 968 parts by mass of stirred water, uniformly dispersed with a homogenizer, and then centrifuged. The filtrate obtained by suction-filtering the supernatant with filter paper.

[0117] Thereafter, the coating agent of Example 3 was sprayed onto the back of the polypropylene balance pan, and immediately dried with hot air from a drier. After repeating these operations several times, the entire balance pan was left to dry overnight in an oven at 50°C, and the film was peeled off from the balance pan to measure its water vapor transmission rate. In addition, the haze value of the coating agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com