Integrated biogas cleaning system to remove water, siloxanes, sulfur, oxygen, chlorides and volatile organic compounds

An organic compound and cleaning system technology, applied in the field of waste biogas cleaning, can solve the problem of not containing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

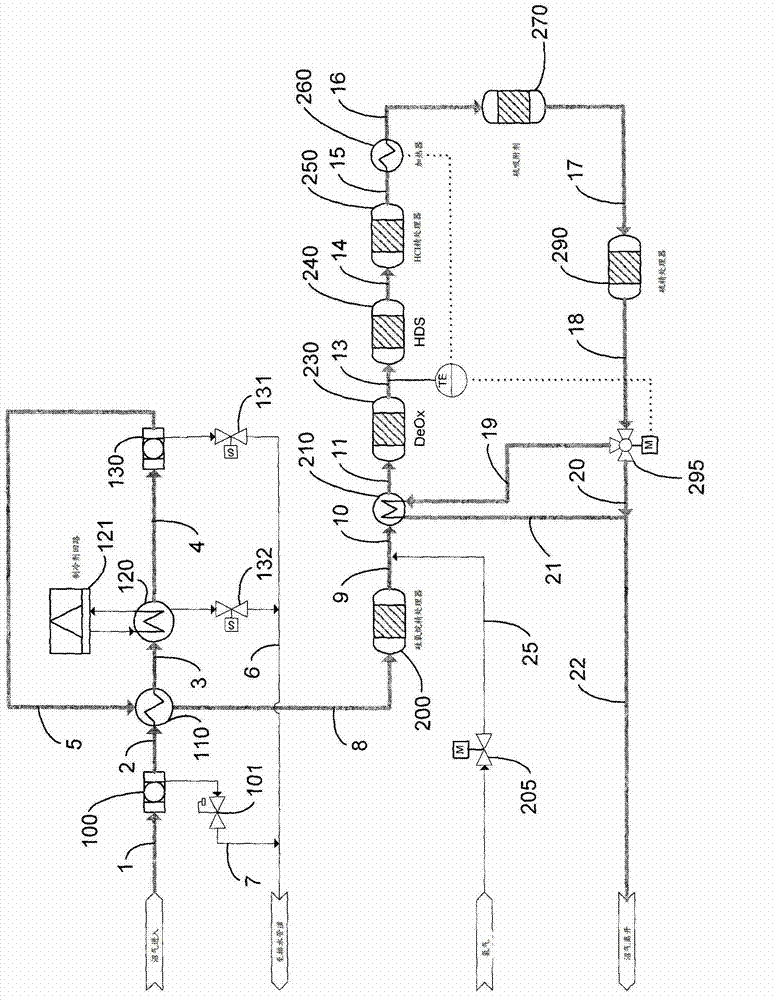

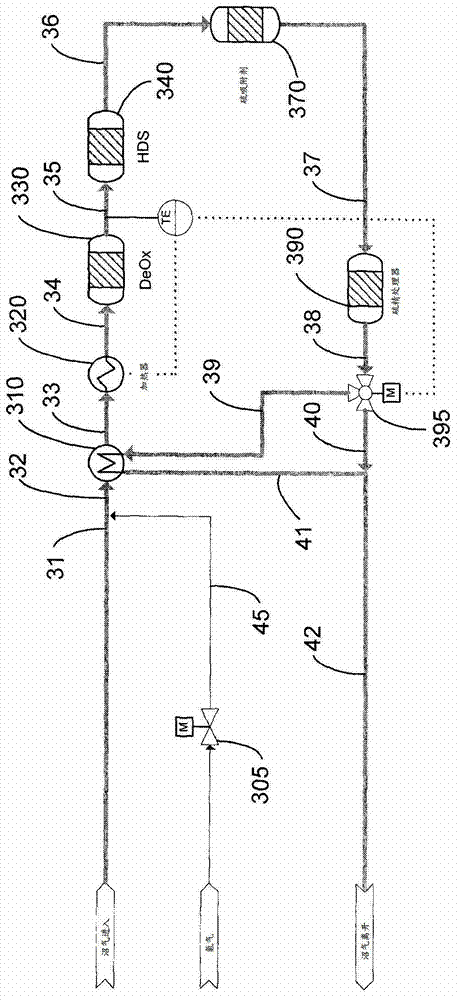

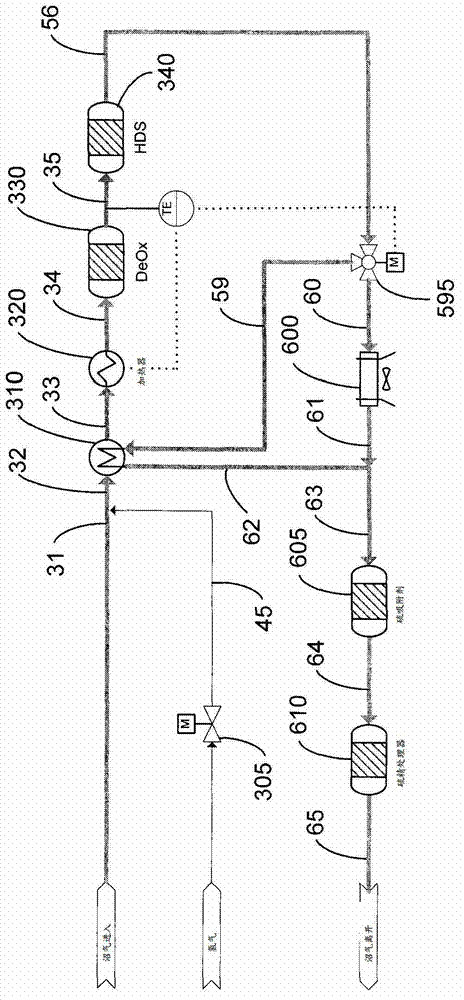

[0057] Biogas cleaning systems and methods satisfying the needs described in the background are provided. There are technical challenges and obstacles in designing and integrating the various conflicting stages of pollutant removal to achieve extremely low concentrations of pollutants. Providing an efficient and improved integrated biogas cleaning system optimized to remove various biogas pollutants in novel technological sequences and combinations requires novel and new designs to integrate processing conditions, material requirements and efficient input temperatures for each stage and the degree of residual pollutant concentration, and compensate for each exposure treatment condition, material requirement and effective input segment and degree of residual pollutant concentration. The embodiments described here have addressed a variety of these unresolved needs in an efficient, efficient and integrated manner, and the most relevant of which are specific solutions for each nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com