Gas-liquid-solid three-phase reactor and applications thereof

A reactor and gas-liquid technology, which is applied in the field of reactors where the reaction materials are gas-liquid-solid three-phase, can solve the problems of small particle backmixing, uneven radial temperature, overheating, etc., and achieve uniform gas-liquid distribution , Catalyst carry less, improve the effect of mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

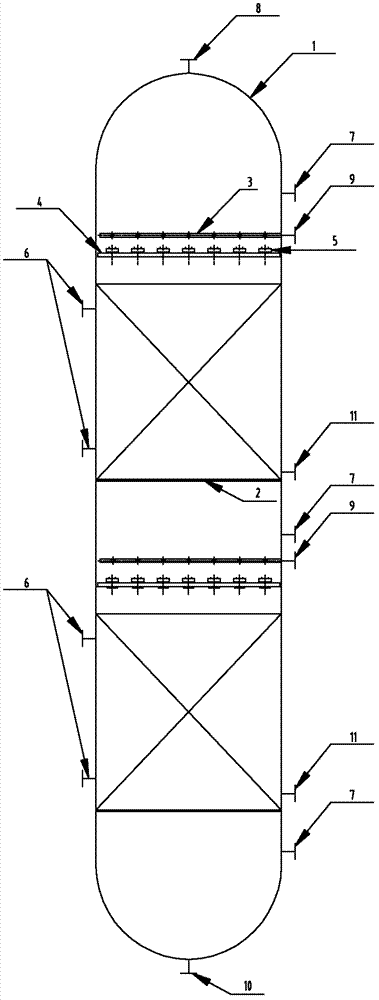

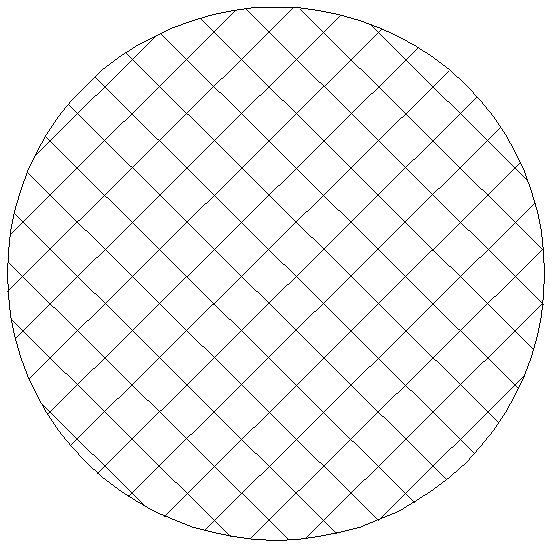

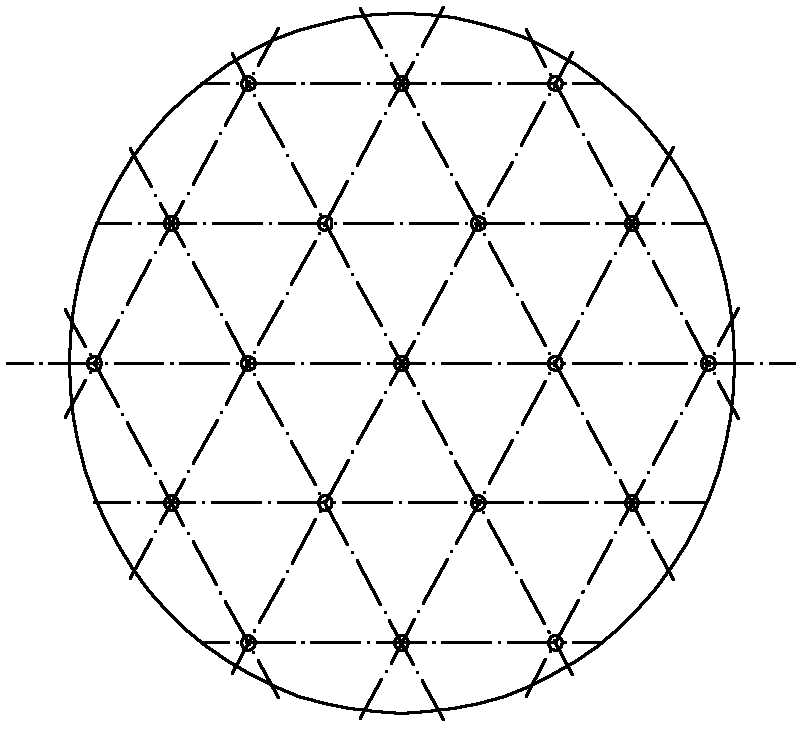

[0031] use figure 1 device of, figure 2 catalyst support plate, image 3 gas-liquid distributor and Figure 4 liquid distributor.

[0032] The height of the reactor cylinder is 1200mm, and the diameter is 500mm. There are two layers of liquid distribution pipes 3 inside, holes of ¢0.5mm and ¢2.0mm, two layers of gas-liquid distributors 4, and 110 distribution caps. Arranged in an equilateral triangle, there are two layers of catalyst support discs 2 with a spacing of 300 mm.

[0033] Inside the reactor cylinder 1, the catalyst support plate 2, the gas-liquid distribution plate 4, the liquid distribution pipe 3, the catalyst support plate 2, the gas-liquid distribution plate 4, and the liquid distribution pipe 3 are arranged sequentially from bottom to top along the axis of the cylinder; Catalyst support plate 2, liquid distribution pipe 3 and gas-liquid distribution plate 4 are arranged along the radial direction of the cylinder;

[0034] The gas-liquid distribution plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com