Full cylinder riding rail type pneumatic saw

A technology of cylinder and reciprocating cylinder, which is applied in the field of rail-riding full-cylinder pneumatic saw and its pneumatic system, can solve the problems of inability to realize the automatic feed of the knife and saw, high machining accuracy requirements, complex structure of the control part, etc., and achieve simple structure, High cutting efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

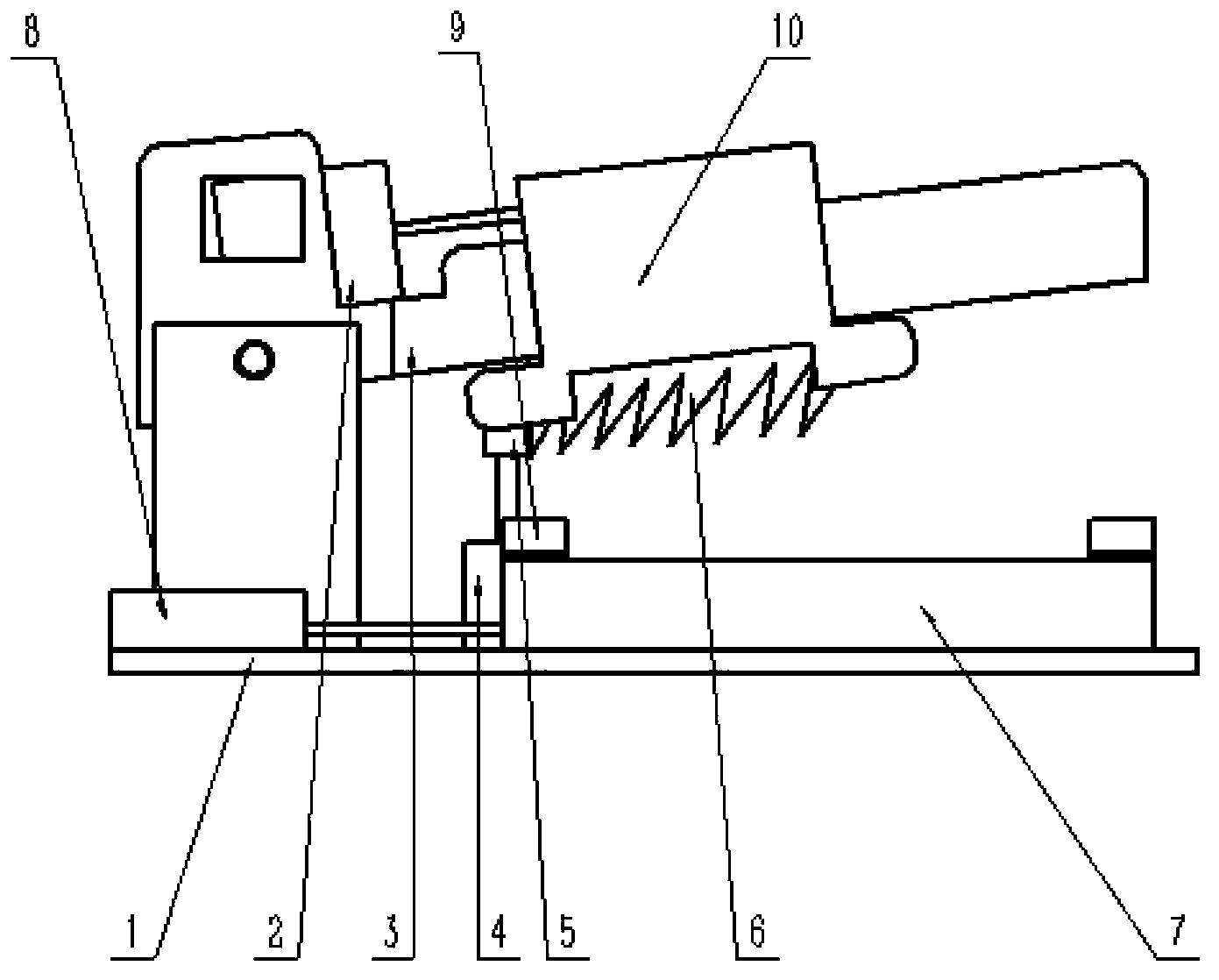

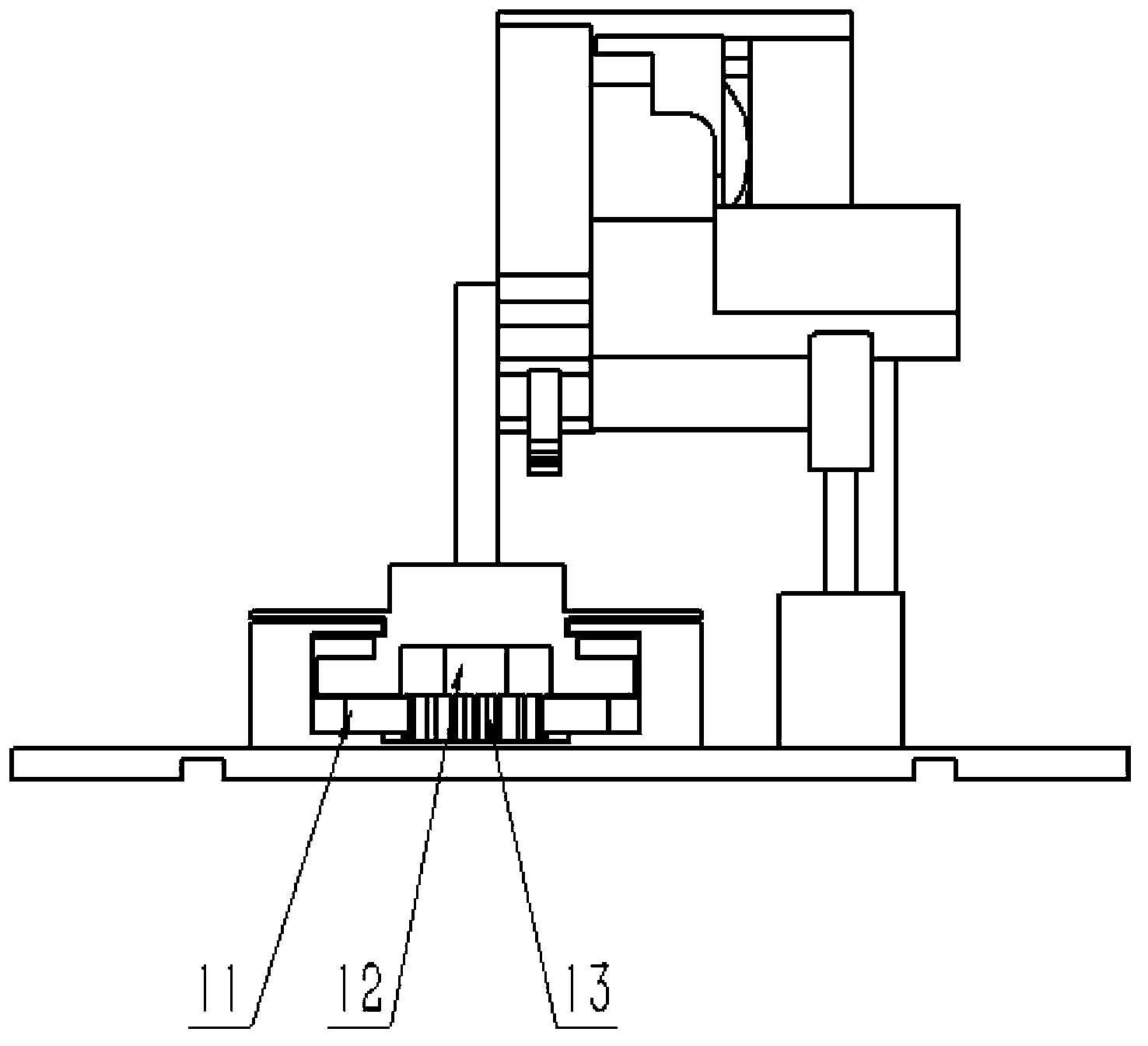

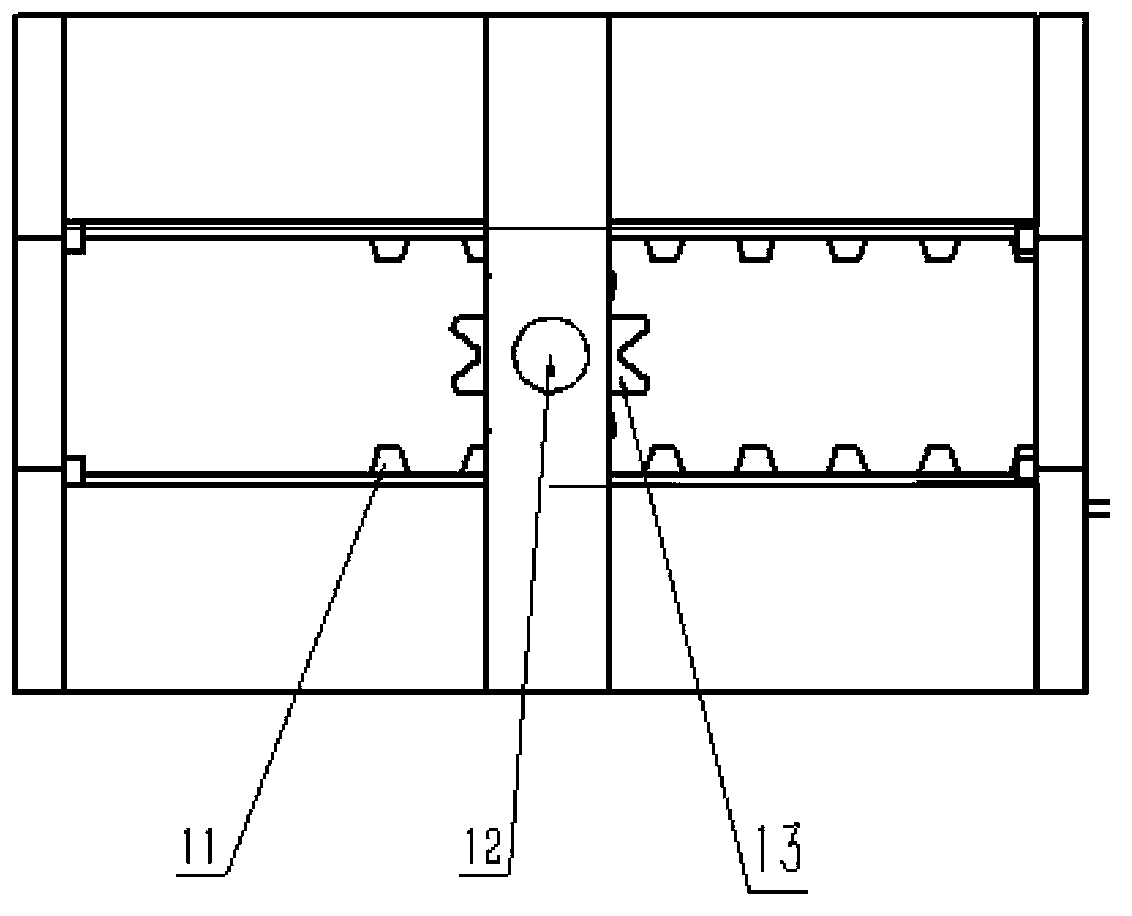

[0020] see figure 1 and figure 2 image 3 , a full-cylinder rail-riding pneumatic saw and its pneumatic system provided by the present invention include a motion cutting mechanism, a pneumatic control system and a pneumatic clamping mechanism arranged below the cutting mechanism for clamping metal materials; the motion cutting The mechanism includes a reciprocating cylinder 2 and a lifting cylinder 4; the reciprocating cylinder 2 is fixed on the saw beam 3, the piston rod of the reciprocating cylinder 2 is connected with the knife rest 10, and the knife rest 10 is controlled to reciprocate on the guide rail of the saw beam 3, and the knife rest Saw blade 6 is installed at the bottom of 10; the lifting cylinder 4 is fixed on the base 1, and is hingedly connected with the saw beam 3 through a connecting rod, and the lifting cylinder 4 realizes the lifting of the saw beam 3; the lifting cylinder 4 and the reciprocating cylinder 2. Cooperate with each other to complete the ...

Embodiment 2

[0029] see Figure 5 , a full-cylinder rail-riding pneumatic saw provided by the present invention, when the three-position four-way valve 24 is switched to the left position, the pressure at the left end of the air control reversing valve 21 is higher than the pressure at the right end due to the gas input, and the valve is pushed The core moves to the left, the air control reversing valve 21 is in the right position, the gas is divided into two branches after passing through the air control reversing valve 21, one branch passes through the pressure reducing valve 17, one-way throttle valve and quick exhaust valve 16 Enter the reciprocating cylinder 2 to realize the forward sawing of the saw blade; at the same time, another gas passes through the pressure reducing valve 18, the one-way throttle valve and the quick exhaust valve 26 and enters the upper chamber of the lifting cylinder 4 to control the downward feeding of the saw beam to realize The saw blade feeds downward whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com