Natural gas hydrogen production reactor and hydrogen production process thereof

A hydrogen production reactor and natural gas technology, applied in the fields of hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of reducing the volume of the reactor, uneven temperature distribution, etc. Take advantage of reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

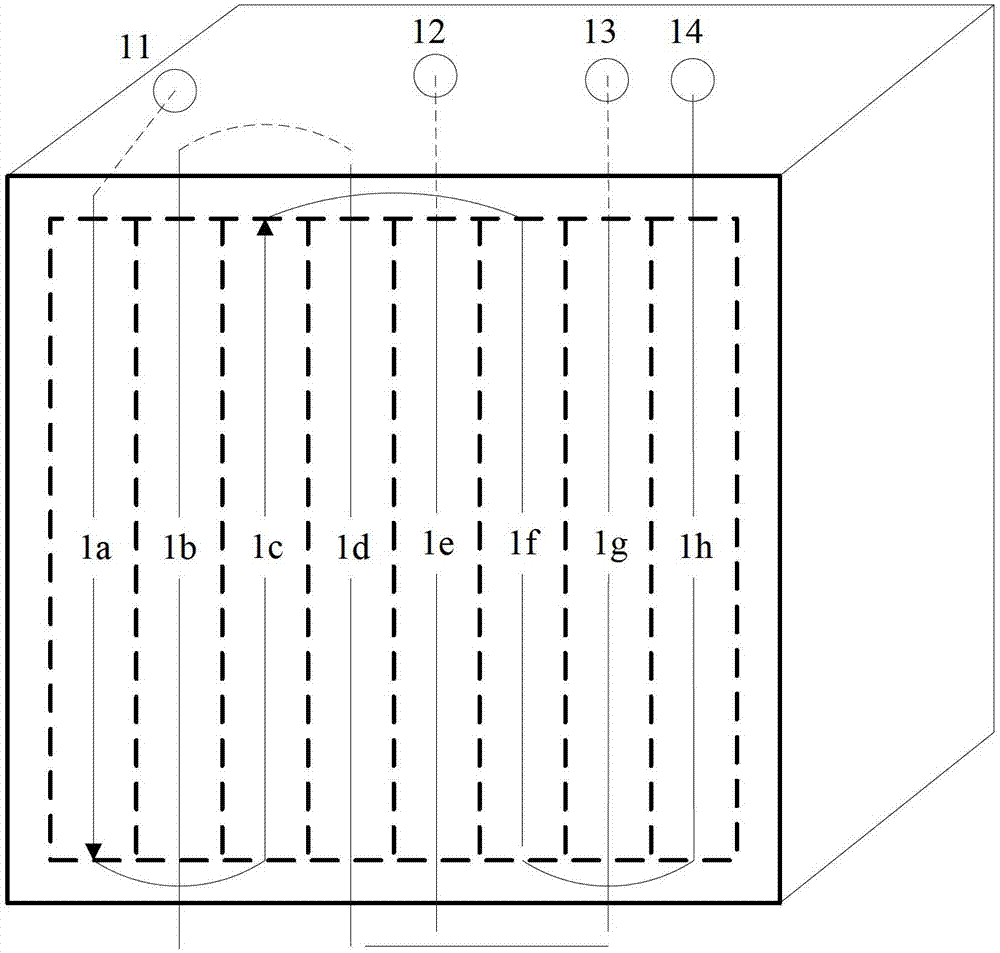

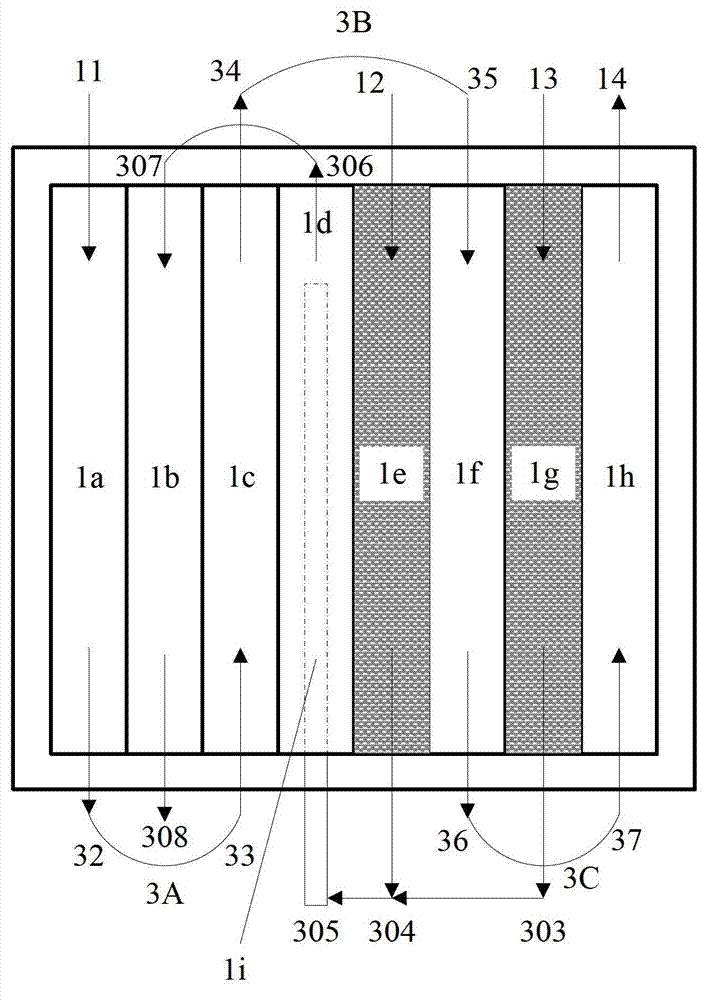

[0029] Natural gas hydrogen production reactor of the present invention ( figure 1), which is composed of a number of different reaction chambers. The whole reactor body adopts a flat structure. From left to right, it includes material gasification (1a), catalytic combustion (1b), reforming (1c), pre-catalysis Multiple areas such as combustion (1d), material preheating (1e), transformation (1f), material preheating (1g) and purification (1h). The natural gas and water required for the hydrogen production reaction enter through the inlet (11), and are provided to the user through the outlet (14) after gasification, reforming, conversion and purification; the energy for the entire hydrogen production process comes from the catalysis of natural gas Combustion reaction, the raw material natural gas and air of the catalytic combustion reaction enter the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com