Self-suction three-mixing pipe two-level jet aeration device

A jet aeration and mixing tube technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to realize convective exchange of water body, inability to ensure uniform dissolved oxygen, and dissolved oxygen power efficiency No high-level problems, to achieve the effect of improving oxygen utilization rate, wide application range, and increasing dissolved oxygen in water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

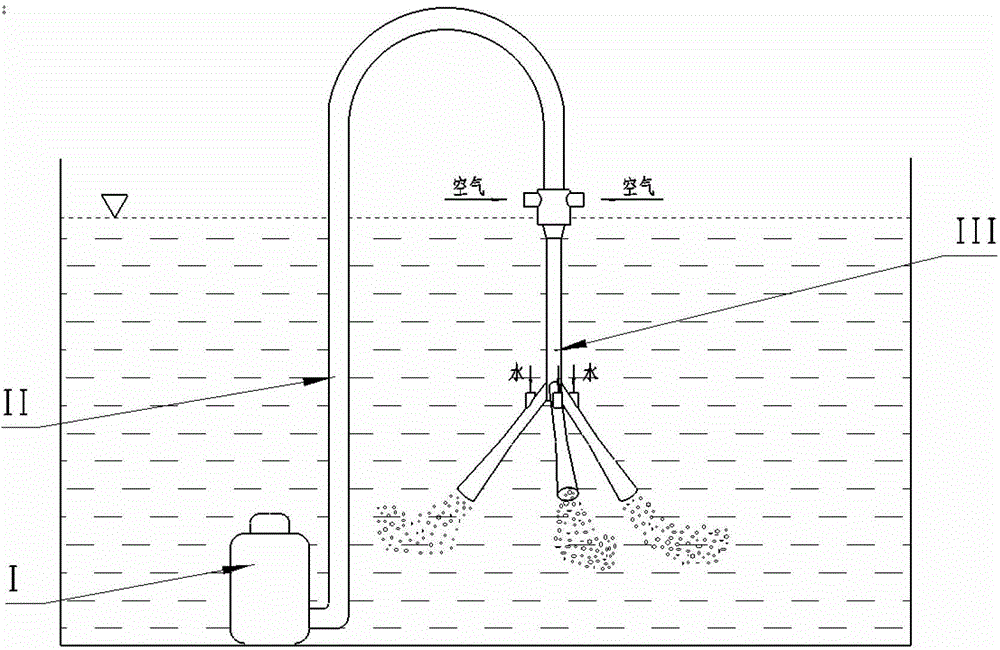

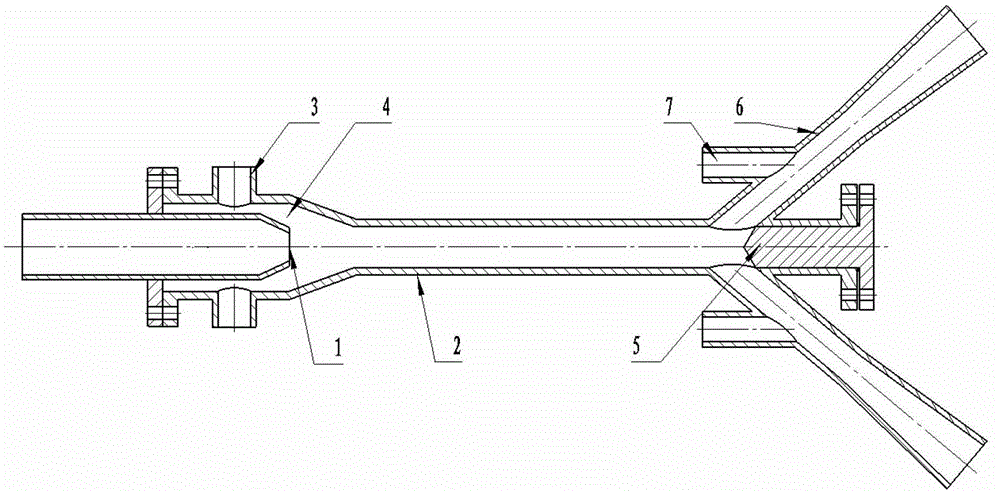

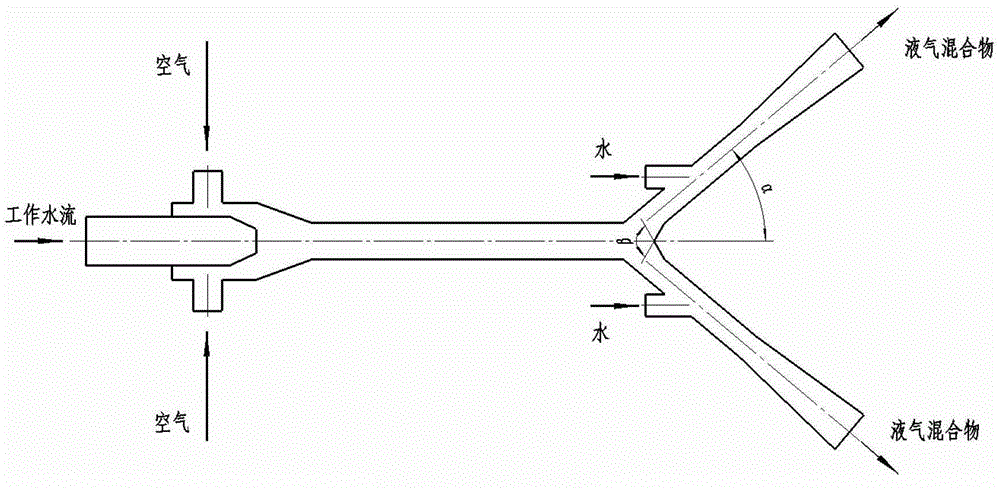

[0017] Such as figure 1 , 2 , Shown in 3, a kind of self-priming type three mixing tube two-stage jet flow aeration device of the present invention is by submersible pump , pipeline system And self-priming three-mixer tube two-stage jet aerator composition. The self-priming three-mixer two-stage jet aerator It is composed of nozzle 1, throat pipe 2, suction pipe 3, suction chamber 4, conical flow divider 5, mixing pipe 6 and water suction pipe 7; submersible pump water outlet and piping system One end connection, piping system The other end of the self-priming three-mixer tube two-stage jet aerator Nozzle 1 connection.

[0018] The suction chamber 4 is a cylindrical cavity with tapered constriction at the bottom, two symmetrically arranged suction pipes 3 are arranged on the side of the cylindrical part of the suction chamber, and the nozzle 1 is installed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com