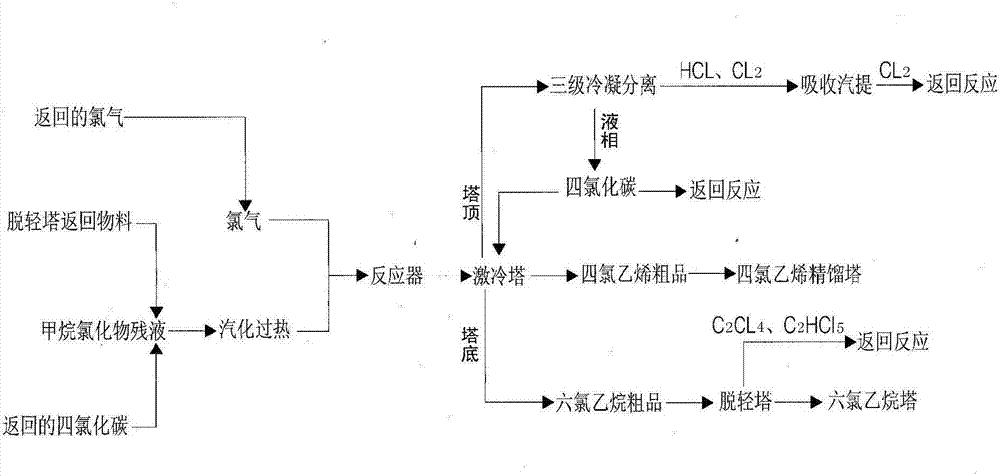

Production process for production of tetrachloroethylene and coproduction of hexachloroethane by using methane chloride residual liquid

A technology of methane chloride and tetrachlorethylene, which is applied in the field of methane chloride residual liquid treatment, to achieve the effect of improving corporate profitability and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

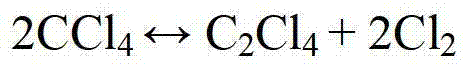

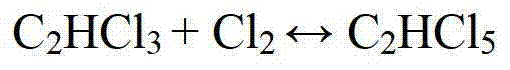

[0026] Methane chloride raffinate containing chloroform, carbon tetrachloride, trichloroethylene, tetrachloroethylene, dichloroethane, tetrachloroethane (ratio: 5%: 50%: 10%: 10%: 15 %: 10%) is vaporized and superheated and mixed with vaporized excess chlorine into the reactor. Under the conditions of 580°C, 0.07MPa, and a reaction time of 8 seconds, the gas phase reaction produces tetrachloroethylene, pentachloroethane, and hexachloroethane. , hydrogen chloride, the mixed gas components are carbon tetrachloride, tetrachloroethylene, hydrogen chloride, excess chlorine, pentachloroethane, hexachloroethane, etc.

[0027] The temperature of the gaseous product is reduced to 86.5°C after being quenched by the quenching tower. The crude product of tetrachlorethylene in the gas phase is extracted from the top side line of the quenching tower, and the gas containing carbon tetrachloride, excess chlorine, and hydrogen chloride passes through the third-stage condenser and the separatio...

Embodiment 2

[0031] Methane chloride raffinate containing chloroform, carbon tetrachloride, trichloroethylene, tetrachloroethylene, dichloroethane, tetrachloroethane (ratio: 8%: 46%: 8%: 12%: 12 %: 14%) is vaporized and superheated and mixed with vaporized excess chlorine into the reactor. Under the conditions of 560°C, 0.05MPa, and a reaction time of 8 seconds, the gas phase reaction produces tetrachloroethylene, pentachloroethane, and hexachloroethane. , Hydrogen chloride. The mixed gas components are carbon tetrachloride, tetrachloroethylene, hydrogen chloride, excess chlorine, pentachloroethane, hexachloroethane, etc.

[0032] The temperature of the gaseous product is reduced to 85.2°C after being quenched by the quenching tower. The crude product of tetrachlorethylene in the gas phase is extracted from the top side line of the quenching tower, and the gas containing carbon tetrachloride, excess chlorine, and hydrogen chloride passes through the third-stage condenser and the separatio...

Embodiment 3

[0036] Methane chloride raffinate containing chloroform, carbon tetrachloride, trichloroethylene, tetrachloroethylene, dichloroethane, tetrachloroethane (ratio: 2%: 48%: 11%: 14%: 12 %: 13%) is vaporized and superheated and mixed with vaporized excess chlorine into the reactor. Under the conditions of 575 ° C, 0.06 MPa, and a reaction time of 9 seconds, the gas phase reaction produces tetrachloroethylene, pentachloroethane, and hexachloroethane. , hydrogen chloride, the mixed gas components are carbon tetrachloride, tetrachloroethylene, hydrogen chloride, excess chlorine, pentachloroethane, hexachloroethane, etc.

[0037] The temperature of the gaseous product is reduced to 88.2°C after being quenched by the quenching tower. The crude product of tetrachlorethylene in the gas phase is extracted from the top side line of the quenching tower, and the gas containing carbon tetrachloride, excess chlorine, and hydrogen chloride passes through the third-stage condenser and the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com