Preparation method for hexabromocyclododecane with high gamma isomer content

A technology of hexabromocyclododecane and water content, which is applied in the preparation of hexabromocyclododecane and the field of hexabromocyclododecane products, can solve the serious side reactions between alcohol solvents and brominating agents and reduce bromination Solvent utilization rate and other issues, to achieve the effect of simplifying the solvent refining process, facilitating dispersion, and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

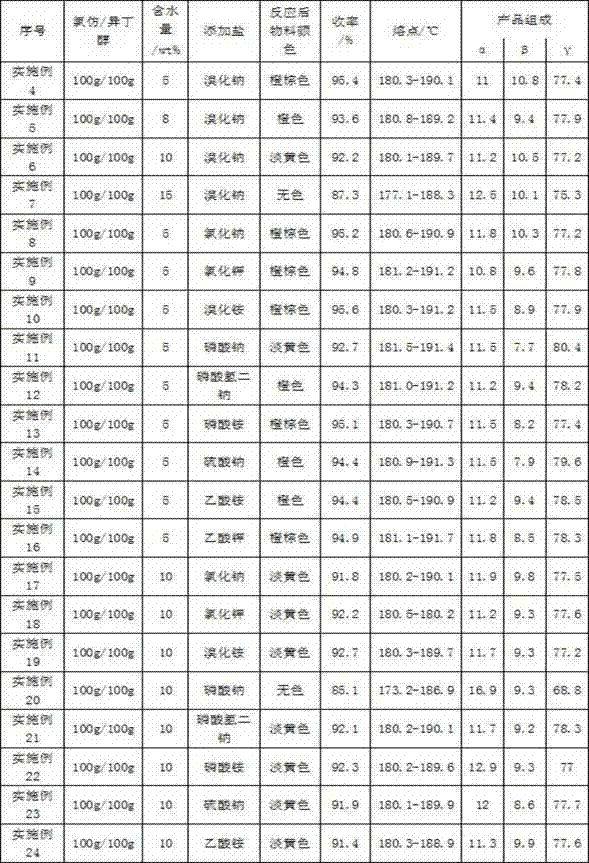

Examples

Embodiment 1

[0029] A mixed solvent with a water content of 2.0wtwt% was prepared, consisting of a mixed solvent composed of 100g of isobutanol, 100g of chloroform, and 4.1g of water.

[0030] In a 500ml four-necked flask, put the mixed solvent prepared above (water content 2.0wt%), turn on the stirrer, and add sodium bromide to a supersaturated state (there is a small amount of sodium bromide that is not completely dissolved). Two 100ml dropping funnels were used to charge 40g (0.25mol) cyclododecatriene and 123.2g (0.77mol) bromine respectively, and part of bromine (3g) was pre-added to the cyclododecatriene before starting to add in the reaction flask. The speed of adding cyclododecatriene and bromine was adjusted so that both were completely added to the reaction flask almost simultaneously. The addition time of cyclododecatriene and bromine is about 150 minutes, and the temperature of the reaction material is controlled at 10-15°C by using an ice-water bath during the entire addition...

Embodiment 2

[0034] As described in Example 1, the difference is that the mixed solvent is composed of 50g chloroform and 150g isobutanol, and the water content in the mixed solvent is 5.0wt%.

[0035] The yield of HBCD is 92.5%, the melting point is 180.5-190.5°C, and the composition of each isomer in the product is 11.8wt%α, 10.1wt%β, 77.8%γ.

Embodiment 3

[0037] As described in Example 1, the difference is that the mixed solvent is composed of 80 g of 1,2-dichloroethane and 100 g of 2-ethylhexanol, and the water content in the mixed solvent is 3.0 wt%.

[0038] The yield of HBCD is 93.2%, the melting point is 182.0-190.5°C, and the composition of each isomer in the product is 10.2wt%α, 8.8wt%β, 80.3wt%γ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com