Method for preparing metallocene polyethylene

A polyethylene and metallocene catalyst technology, applied in the field of metallocene polyethylene preparation, can solve the problems of poor resin processing performance, narrow resin molecular weight distribution, difficulty in catalyst selection, etc., achieve good processing performance, easy preparation, and simple catalyst structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

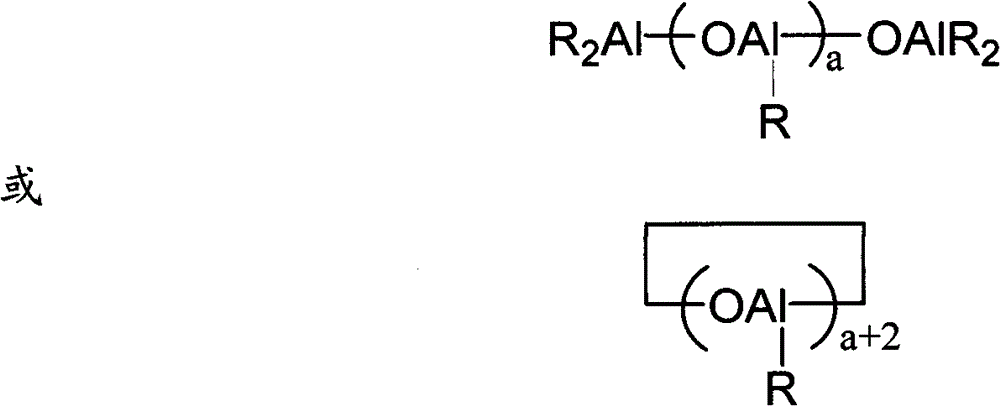

Method used

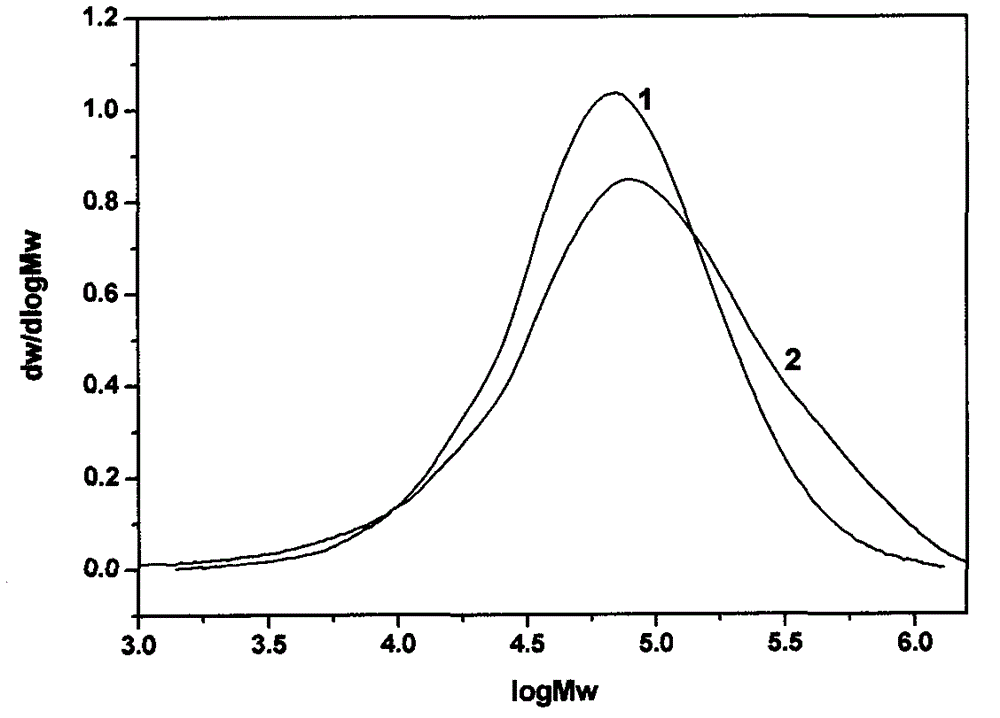

Image

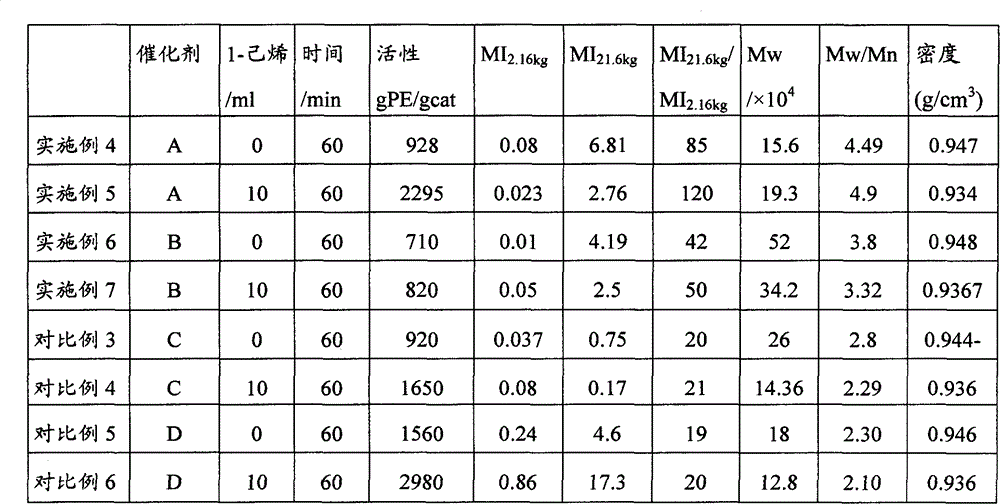

Examples

Embodiment 1

[0035] The preparation of embodiment 1 load type MAO (SMAO)

[0036] Add 20 grams of activated 955 silica gel (activation condition 600°C, 4 hours) into a 250ml glass bottle replaced with nitrogen, add 30ml of toluene, raise the temperature of the system to 50°C, add dropwise the toluene solution of MAO (11g MAO), and react After 4 hours, filter, wash 3 times with 30ml toluene, then wash 2 times with hexane, and drain to obtain a white carrier with good fluidity, Al%: ~14 (ICP).

Embodiment 2

[0037] The preparation of embodiment 2 supported catalyst A

[0038] In the 250ml glass bottle replaced with nitrogen, add 2g of SMAO prepared in Example 1, add 20ml of toluene, start stirring, add dropwise 10ml of compound EtInd at room temperature 2 ZrCl 2 Toluene solution (containing 43mg compound, Al / Zr=100), reacted under stirring for 30min, filtered, washed with 30ml hexane, filtered, and dried to obtain an orange powder with good fluidity, that is, catalyst A.

Embodiment 3

[0039] The preparation of embodiment 3 supported catalyst B

[0040] In the 250ml glass bottle replaced with nitrogen, add 2g of SMAO prepared in Example 1, add 20ml of toluene, start stirring, add dropwise 10ml of compound Me at room temperature 2 SiInd 2 ZrCl 2 Toluene solution (containing 47mg compound, Al / Zr=100), reacted under stirring for 30min, filtered, washed with 30ml hexane, filtered and dried to obtain a light yellow powder with good fluidity, that is, catalyst B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com