A kind of conductive polyphenylene ether alloy and preparation method thereof

A polyphenylene ether and alloy technology, applied in the field of conductive polyphenylene ether alloy and its preparation, can solve the problems of poor mechanical properties of materials, poor melt fluidity, and deteriorated processing performance, and achieve small processing performance, improve processing performance, and improve oil resistance and solvent resistance effects

Active Publication Date: 2016-12-28

GUANGZHOU SUPER DRAGON ENG PLASTICS

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to its high melting point, poor melt fluidity, and difficult processing, the addition of conductive fillers will further deteriorate the processing performance, and will also have a negative impact on the mechanical properties of the material, ultimately limiting its application.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0044] The following examples will further describe the present invention, but the present invention should not be limited by these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

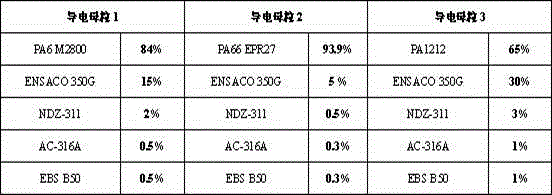

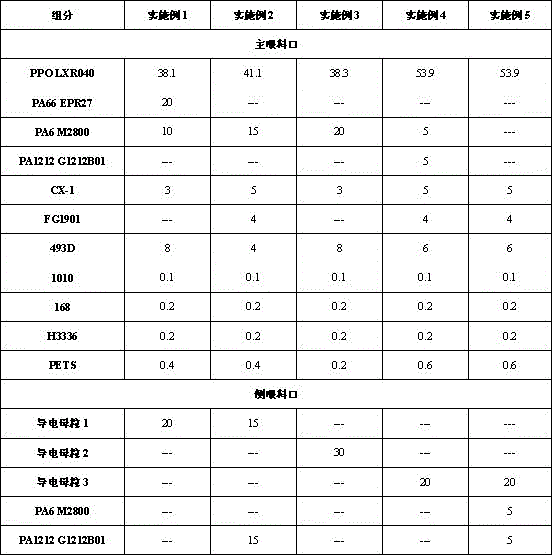

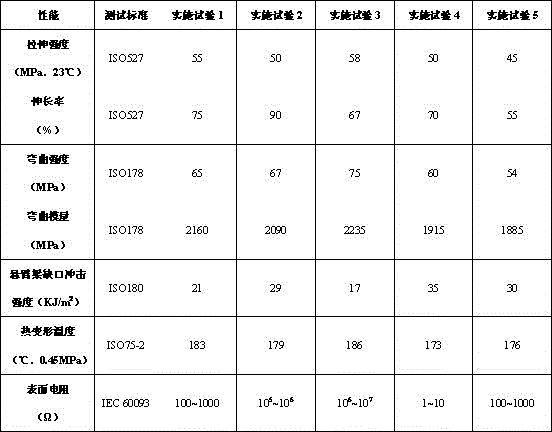

The invention discloses a conductive polyphenylether alloy and a preparation method of the conductive polyphenylether alloy. The alloy consists of the following components: polyphenylether resin, nylon resin, conductive carbon black, a compatilizer, a flexibilizer, a coupling agent, an antioxidant, a lubricating agent and a dispersing agent. The preparation method comprises the following two steps: 1, preparing conductive master-batches by using the nylon as a matrix; and 2, blending the polyphenylether, the nylon, the conductive master-batches, the compatilizer, the flexibilizer and the like to prepare a conductive polyphenylether alloy. The nylon is adopted as a second resin component of the matrix in the conductive polyphenylether alloy disclosed by the invention; and compared with the normal polyphenylether / polystyrene alloys, the heat resistance property of the material is better and the oil resistance and the solvent resistance are greatly improved.

Description

technical field [0001] The invention relates to the field of modified plastics, in particular to a conductive polyphenylene ether alloy and a preparation method thereof. Background technique [0002] Polyphenylene ether (PPO) is non-toxic, transparent, and has low relative density. It has excellent mechanical strength, stress relaxation resistance, creep resistance, heat resistance, water resistance, water vapor resistance, and dimensional stability. Good electrical properties in the frequency range, no hydrolysis, small molding shrinkage, flame retardant and self-extinguishing, and a series of excellent properties. [0003] As a functional material, conductive high polymer material has the characteristics of light weight (low density), easy molding and processing, electrical conductivity and products can be completed at one time, wide range of resistivity adjustment, low cost, and easy structure adjustment, etc., and is of great importance in many fields. Applications. (1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L71/12C08L77/00C08L77/02C08L77/06C08K13/06C08K9/06C08K9/04C08K3/04C08J3/22

Inventor 郝源增任萍郝建鑫黄泽宾

Owner GUANGZHOU SUPER DRAGON ENG PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com