Surface treatment method and application of heat-conducting packing

A thermally conductive filler and surface treatment technology, applied in fibrous fillers, dyed organosilicon compound treatments, etc., can solve the problems of high hardness, insufficient thermal conductivity, and inability to achieve softness of thermally conductive silicone sheets, and achieve low hardness, Conducive to environmental protection and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

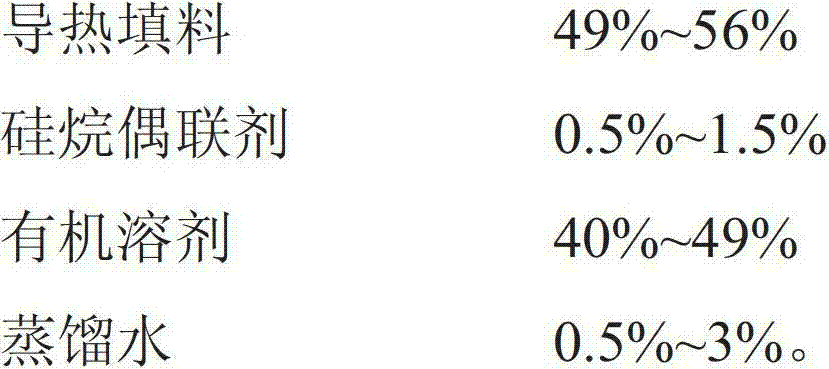

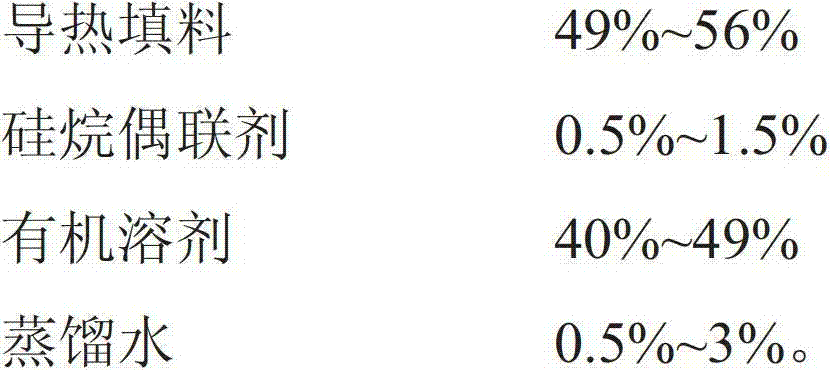

[0030] Embodiment 1: the surface treatment method of the thermally conductive filler provided by this embodiment, it comprises the following steps:

[0031] (1) Weighing silane coupling agent, organic solvent and distilled water respectively in proportion, wherein said organic solvent is 95% ethanol, absolute ethanol or isopropanol;

[0032] (2) Add the organic solvent and distilled water weighed in step (1) into the silane coupling agent in turn, stir and mix evenly, then drop into the acid solution, adjust the pH value of the mixed solution to 3.5-5.5, and then Let it stand for 5-30 minutes under certain conditions, and set aside;

[0033] (3) Weighing the thermally conductive filler, heating the mixed solution prepared in step (2) to 50-80° C., and maintaining the temperature, adding the thermally conductive filler into the mixed solution, stirring under reflux for 2 to 6 hours, and filtering out the thermally conductive filler;

[0034] (4) Put the heat-conducting filler ...

Embodiment 2

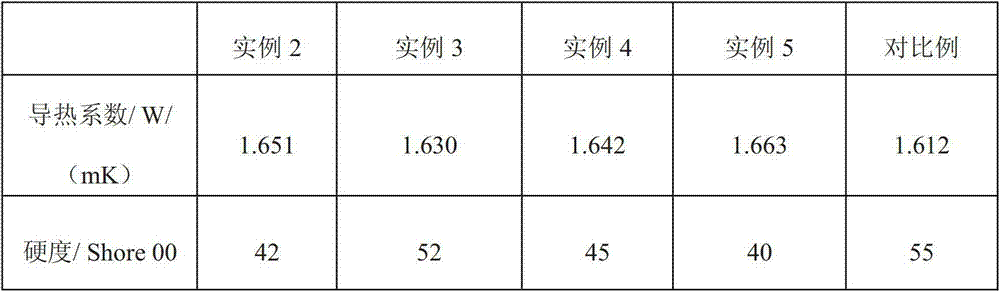

[0044] Embodiment 2: This embodiment provides a surface treatment method and application of a thermally conductive filler. The method steps are basically the same as those in Embodiment 1, except that:

[0045] The surface treatment method of thermally conductive filler, it may further comprise the steps:

[0046] (1) Weigh 2 g of 16-alkyl trimethoxysiloxane, 196 g of 95% ethanol, and 2 g of distilled water;

[0047] (2) Add the 95% ethanol and distilled water weighed in step (1) into 16 alkyltrimethoxysiloxane successively, after stirring and mixing evenly, drop into dilute glacial acetic acid solution, and adjust the pH value of the mixed solution to 5.5, then stand at 25°C for 20 minutes, and set aside;

[0048](3) Weigh 200g of alumina with a median particle size of 45 microns and 5 microns, mix them in a mass ratio of 6:4, heat the mixed solution prepared in step (2) to 60°C, and keep the temperature, add the alumina mixture Into the mixed solution, after reflux and sti...

Embodiment 3

[0051] Embodiment 3: The surface treatment method and application of the thermally conductive filler provided in this embodiment, the method steps are basically the same as those in Embodiment 1 and 2, the difference is that:

[0052] The surface treatment method of thermally conductive filler, it may further comprise the steps:

[0053] (1) Weigh KH7924g, absolute ethanol 146g, distilled water 10g;

[0054] (2) Add the anhydrous ethanol and distilled water weighed in step (1) into KH792 in turn, stir and mix evenly, then drop in dilute glacial acetic acid solution, adjust the pH value of the mixed solution to 4.8, and Let stand for 10 minutes, set aside;

[0055] (3) Weigh 200 g of aluminum nitride, heat the mixed solution prepared in step (2) to 50° C., and keep the temperature, add aluminum nitride to the mixed solution, stir under reflux for 6 hours, and filter out the aluminum nitride;

[0056] (4) Put the aluminum nitride filtered out in step (3) into an oven, and bake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com