Water-based nano heat insulation material and preparation method thereof

A nano-insulation and thermal insulation material technology, applied in the direction of coating, can solve the problems of water failure, difficult to achieve thermal insulation and energy saving effect, poor thermal conductivity, etc., to prevent temperature conduction and improve thermal insulation technology performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

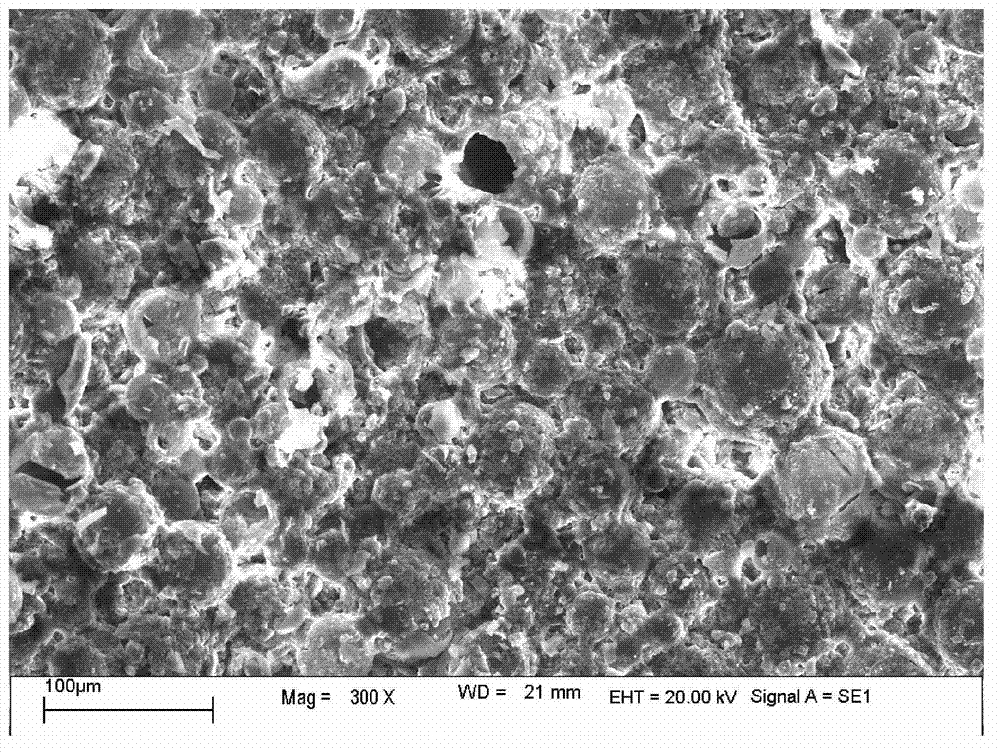

Image

Examples

Embodiment 1

[0206] Embodiment 1: Preparation of water-based nano heat insulation material

[0207] The implementation steps of this embodiment are as follows:

[0208] A. Preparation of porous aqueous nano-SiO 2 suspoemulsion

[0209] With 16 parts by weight of the water-based acrylic emulsion sold under the trade name Pure Acrylic Emulsion EC-1791 by U.S. Dow Company, 30 parts by weight of the water-based acrylic viscosity emulsion sold under the trade name Pure Acrylic Emulsion 568 by Beijing Rohm and Haas Chemical Co., Ltd. , 26 parts by weight of the elastic emulsion sold by Beijing Oriental Tomorrow Chemical Co., Ltd. under the trade name elastic emulsion 728 and 7 parts by weight according to the porous water-based nano-SiO prepared by the method described in ZL96117042.5 2 Put it into the homogeneous emulsifier sold by Shanghai Shenghaiwei Electric Instrument Co., Ltd. and stir and mix to make porous water-based nano-SiO 2 Fully dispersed in these emulsions, miscible and evenly ...

Embodiment 2

[0215] Embodiment 2: the preparation of water-based nano thermal insulation material

[0216] The implementation steps of this embodiment are as follows:

[0217] A. Preparation of porous aqueous nano-SiO 2 suspoemulsion

[0218] With 22 parts by weight of the water-based acrylic emulsion sold under the trade name pure acrylic emulsion EC-1791 by U.S. Dow Company, 35 parts by weight of the water-based acrylic viscous emulsion sold under the trade name pure acrylic emulsion 568 by Beijing Rohm and Haas Chemical Co., Ltd. 32 parts by weight of the elastic emulsion sold by Beijing Oriental Tomorrow Chemical Co., Ltd. under the trade name pure acrylic emulsion 728 and 13 parts by weight of the porous water-based nano-SiO prepared according to the method described in ZL96117042.5 2 Put it into the homogeneous emulsifier sold by Shanghai Shenghaiwei Electric Instrument Co., Ltd. and stir and mix to make porous water-based nano-SiO 2 Fully dispersed in these emulsions, miscible an...

Embodiment 3

[0224] Embodiment 3: the preparation of water-based nano thermal insulation material

[0225] The implementation steps of this embodiment are as follows:

[0226] A. Preparation of porous aqueous nano-SiO 2 suspoemulsion

[0227] With 15 parts by weight of the water-based acrylic emulsion sold under the trade name pure acrylic emulsion EC-1791 by U.S. Dow Company, 31 parts by weight of the water-based acrylic emulsion sold under the trade name pure acrylic emulsion 568 by Beijing Rohm and Haas Chemical Co., Ltd., 25 parts by weight are prepared by the elastic emulsion of trade name elastic emulsion 728 and 5 parts by weight according to the method described in ZL96117042.5 by Beijing Oriental Tomorrow Chemical Co., Ltd. 2 Put it into the homogeneous emulsifier sold by Shanghai Shenghaiwei Electric Instrument Co., Ltd. and stir and mix to make porous water-based nano-SiO 2 Fully dispersed in these emulsions, miscible and evenly compounded, a porous water-based nano-SiO 2 su...

PUM

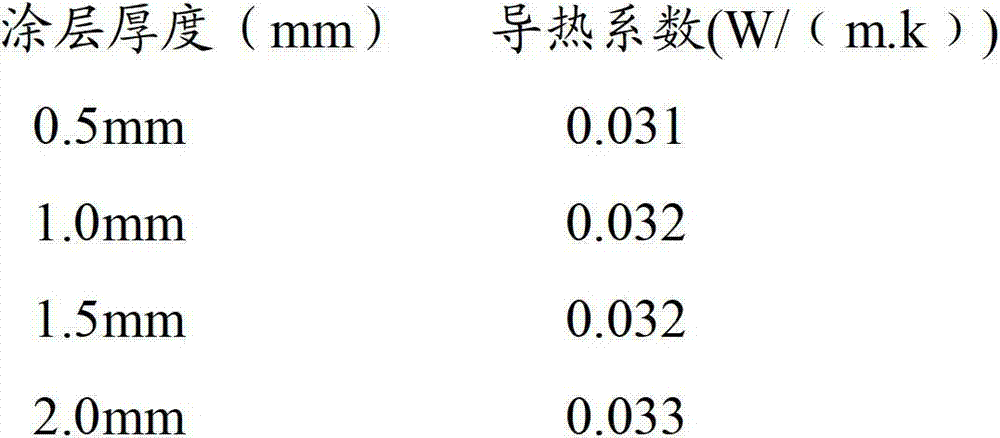

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com