Slurry composition and use thereof

A composition and slurry technology, which is applied to polishing compositions containing abrasives, grinding machines, grinding devices, etc., can solve problems such as falling off from the machine, high grinding temperature, and grinding failure, and achieve improved stability and reliability. Higher temperature, lower grinding temperature, and better grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

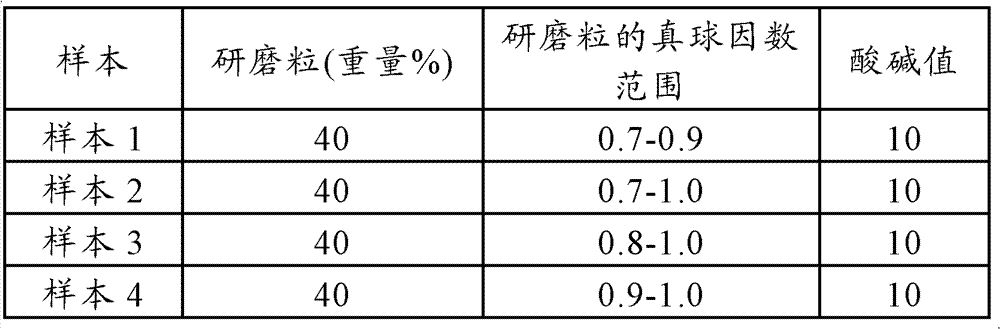

[0047]Experimental Example 1 is used to test the influence of the spherical factor of the abrasive grains in the slurry composition on the grinding temperature and removal rate. In Experimental Example 1, colloidal silica (colloidal silica) with an average particle diameter of 90 nanometers to 130 nanometers and a particle diameter polydistribution index of 1.0 to 1.4 was used as abrasive particles to prepare samples 1 to 4. For the slurry composition, the true spherical factor range, composition, ratio and pH value of the abrasive grains are shown in Table 1 below, and the rest of the abrasive composition is water.

[0048] Table 1

[0049]

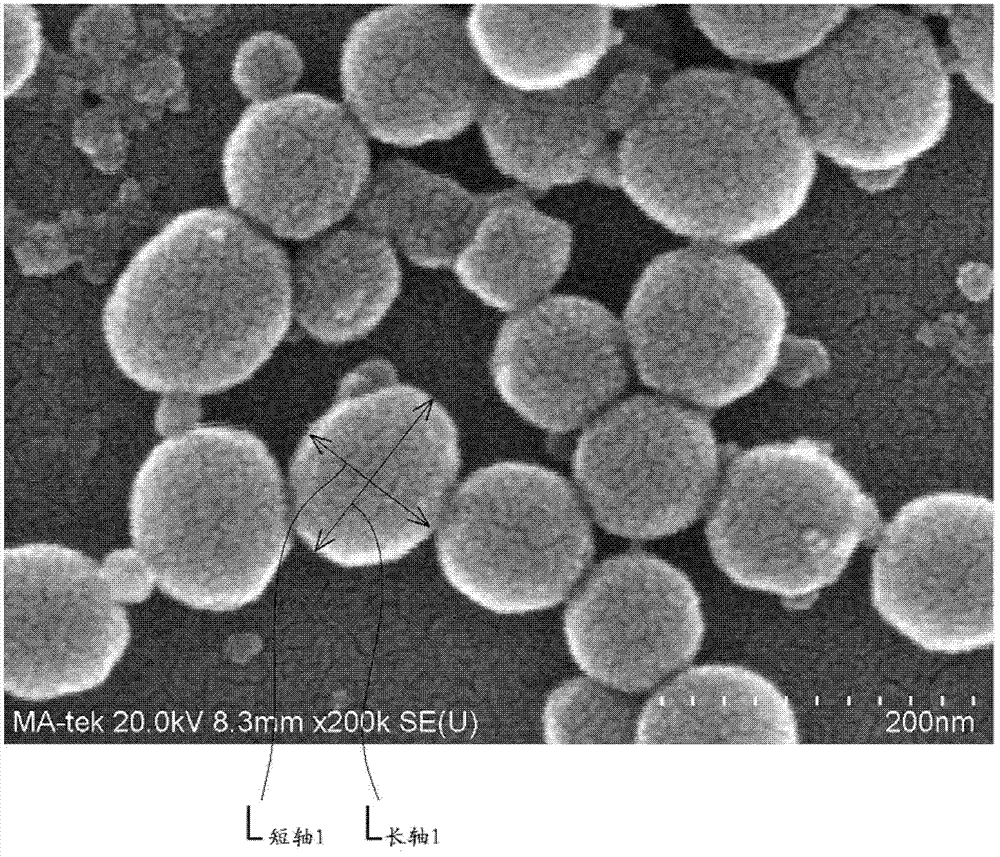

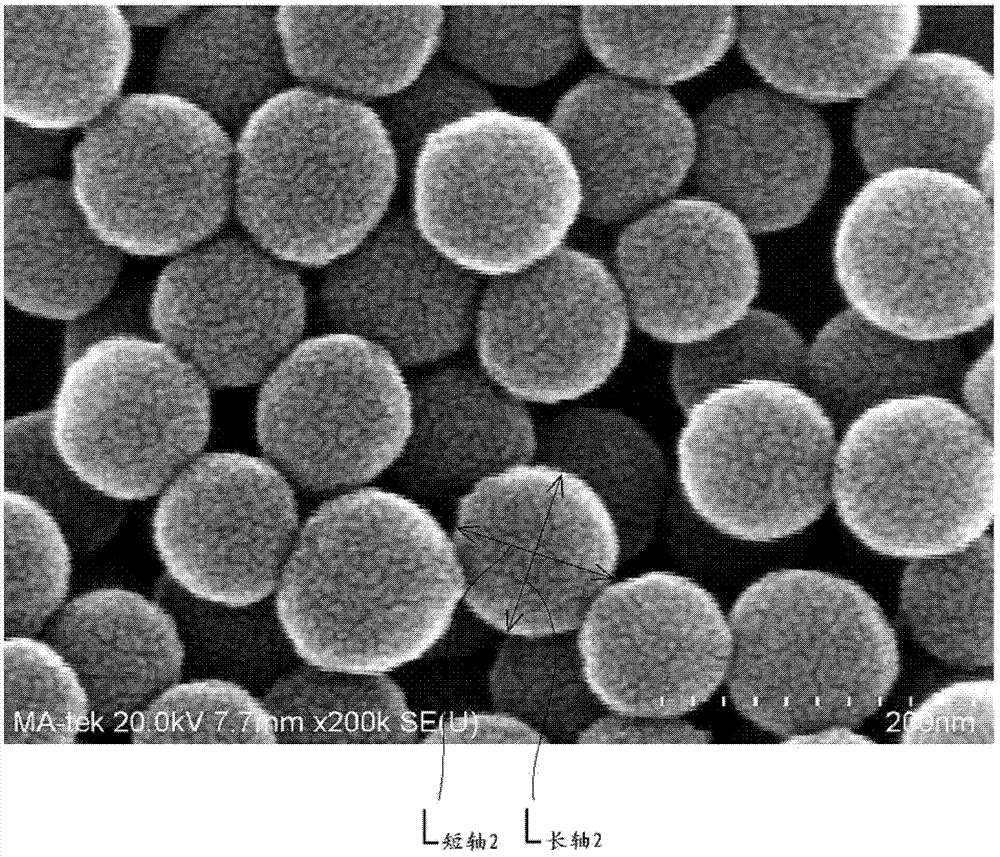

[0050] figure 1 A scanning electron microscope photograph of sample 2 is shown. figure 2 A scanning electron microscope photograph of sample 4 is shown.

[0051] Please refer to figure 1 , due to the true spherical factor range of the abrasive grains of sample 2 is 0.7-1.0, so sample 2 contains a large number of elliptical abra...

experiment example 2

[0058] Experimental Example 2 is used to test the effect of additives in the slurry composition on the grinding temperature and removal rate. In Experimental Example 2, colloidal silica with an average particle size of 90 nm to 130 nm and a particle size polydistribution index of 1.0 to 1.4 was used as abrasive particles to prepare slurry compositions of samples 5 to 8, The true spherical factor range, composition, ratio and pH value of the abrasive grains are shown in Table 3 below.

[0059] table 3

[0060]

[0061] The experimental results of Experimental Example 2 are shown in Table 4 below.

[0062] Table 4

[0063]

[0064]

[0065] From the experimental results in Table 4 above, it can be seen that comparing the experimental results of samples 6-8 with sample 5, no matter adding surfactants (such as sodium lauryl sulfate and / or sodium lauryl glutamate) or Adding an antifoaming agent (such as polydimethylsiloxane) can further control the grinding temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com