Wood fiber pretreatment liquid and manufacturing method of fiberboard

A pretreatment liquid and wood fiber technology, which is applied in the pretreatment of molding materials, manufacturing tools, flat products, etc., can solve the problems of unbreakable fiber yield, increased production energy consumption, high energy consumption, etc., and achieve the reduction of control requirements, Ease of control and high fiber yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

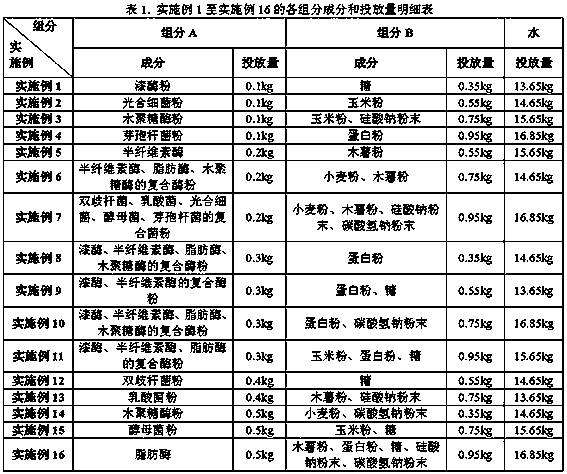

[0042] Embodiment 1: A kind of lignocellulosic pretreatment liquid, is made by stirring and mixing component A, component B and water. Component A is laccase powder, and the dosage is 0.1kg; component B is sugar, and the dosage is 0.35kg; water, 13.65kg. 14.1kg per serving.

Embodiment 2

[0043] Embodiment 2: A kind of lignofiber pretreatment liquid, which is formed by stirring and mixing component A, component B and water. Component A is photosynthetic bacteria powder, and the dosage is 0.1kg; component B is corn flour, and the dosage is 0.55kg; water, 14.65kg. 15.3kg per serving.

Embodiment 3

[0044] Embodiment 3: A kind of lignofiber pretreatment liquid, which is formed by stirring and mixing component A, component B and water. Component A is xylanase powder, and the dosage is 0.1kg; component B includes corn flour, and the dosage is 0.69kg, and sodium silicate powder, and the dosage is 0.06kg, 0.75kg in total; water, 15.65kg. 16.5kg per serving.

[0045] A kind of manufacturing method of the fiber board that has utilized the pretreatment liquid of embodiment 1 to embodiment 3, comprises the following steps in sequence:

[0046] S1. Log steaming and chipping treatment, the log or branch wood is steamed for 8 hours, and the steamed log or branch wood is chipped.

[0047] S2. The process of preparing the pretreatment solution, according to the dosage of the embodiment 1 to the embodiment 3, component A, component B and water are placed in the container, after stirring, stand at room temperature for 12 hours.

[0048] S3. The process of pretreatment, before the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com