Bismuth-doped vanadate fluorescent powder and preparation method thereof

A technology of vanadate and phosphor, applied in the field of bismuth-doped vanadate phosphor and its preparation, can solve the problems of weak luminescence, low color rendering index, lack of yellow phosphor, etc., and achieve the effect of avoiding saturation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

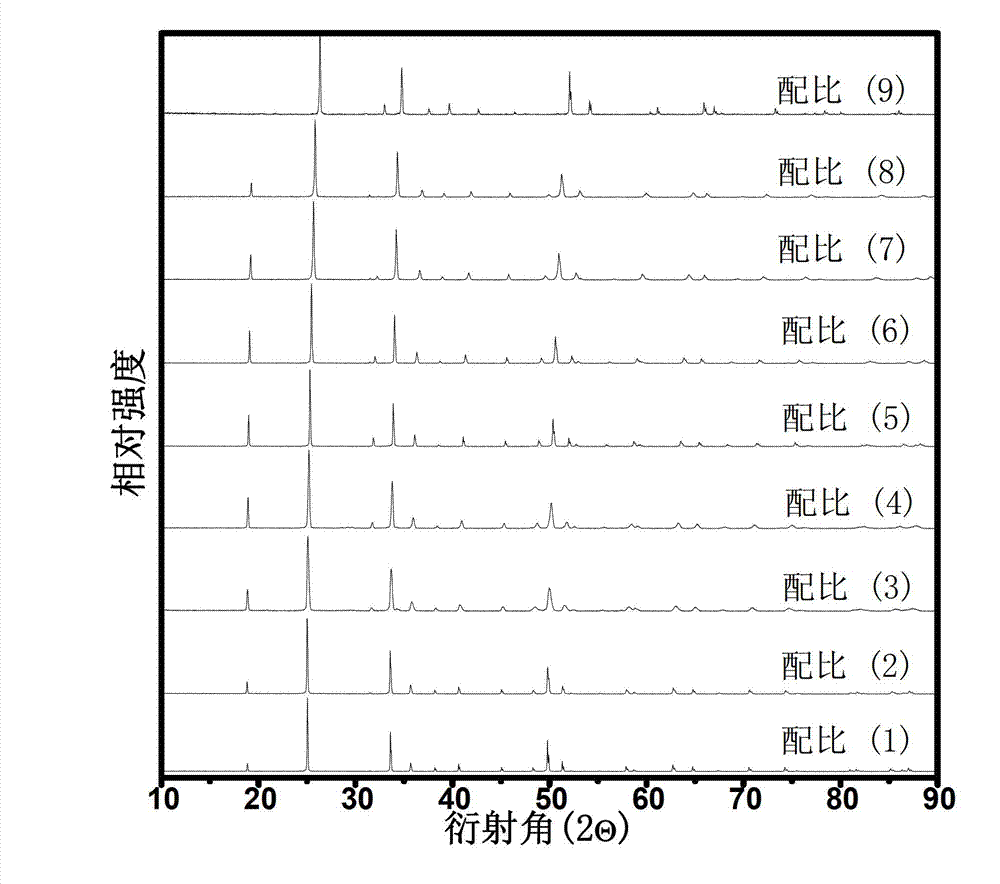

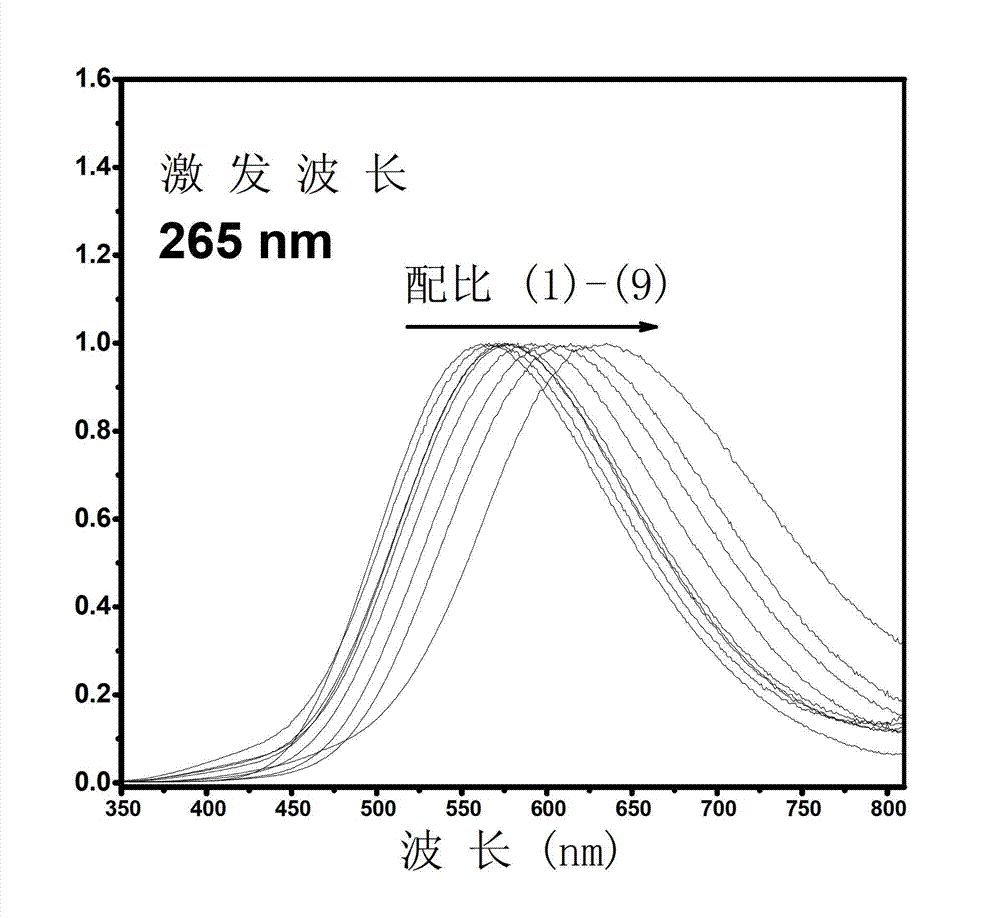

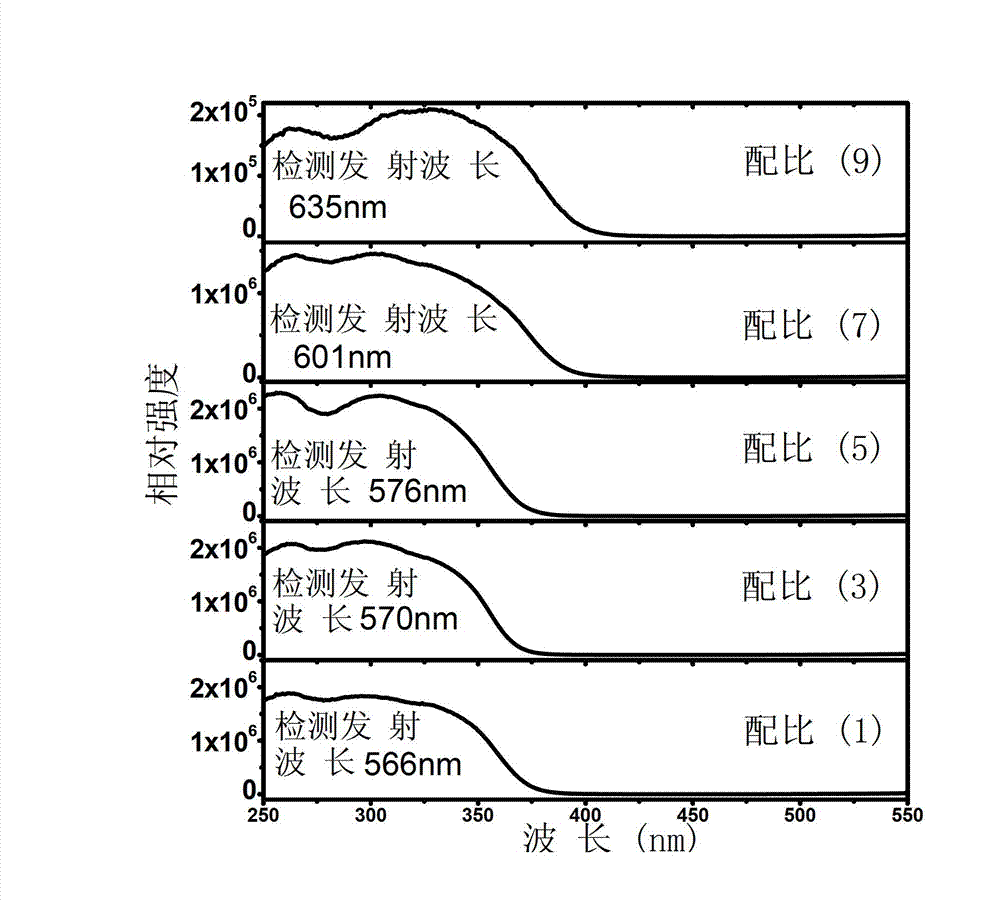

[0028] Select yttrium oxide, lutetium oxide, scandium oxide, ammonium vanadate, bismuth oxide as starting compound raw materials, press Y a Lu b sc c VO 4 : The element molar ratio ratio shown in d%Bi, respectively weigh five kinds of compound raw materials, a total of 9 groups, the ratio is as follows:

[0029] (1) Y: Lu: Sc: V = 1: 0: 0: 1, corresponding to a = 1, b = 0, c = 0, bismuth replaces 2% of Y, that is, d% = 2%;

[0030] (2) Y: Lu: Sc: V = 0.8: 0.2: 0: 1, corresponding to a = 0.8, b = 0.2, c = 0, bismuth replaces 2% (Y, Lu), that is, d% = 2%;

[0031] (3) Y: Lu: Sc: V = 0.6: 0.4: 0: 1, corresponding to a = 0.6, b = 0.4, c = 0, bismuth replaces 2% (Y, Lu), that is, d% = 2%;

[0032] (4) Y: Lu: Sc: V = 0.4: 0.6: 0: 1, corresponding to a = 0.4, b = 0.6, c = 0, bismuth replaces 2% (Y, Lu), that is, d% = 2%;

[0033] (5) Y: Lu: Sc: V = 0: 1: 0: 1, corresponding to a = 0, b = 1, c = 0, bismuth replaces 2% of Lu, that is, d% = 2%;

[0034] (6) Y: Lu: Sc: V = 0: 0.8: ...

Embodiment 2

[0044] Select yttrium nitrate, lutetium nitrate, scandium nitrate, vanadium oxide, bismuth powder as starting compound raw materials, press Y a Lu b sc c VO 4 : The element molar ratio ratio shown in d%Bi, respectively weigh five kinds of compound raw materials, a total of 7 groups, the ratio is as follows:

[0045] (1) Y: Lu: Sc: V = 0: 1: 0: 1, corresponding to a = 0, b = 1, c = 0, bismuth replaces 0.01% of Lu, that is, d% = 0.01%;

[0046] (2) Y: Lu: Sc: V = 0: 1: 0: 1, corresponding to a = 0, b = 1, c = 0, bismuth replaces 1.00% of Lu, that is, d% = 1.00%;

[0047] (3) Y: Lu: Sc: V = 0: 1: 0: 1, corresponding to a = 0, b = 1, c = 0, bismuth replaces 2.00% of Lu, that is, d% = 2.00%;

[0048] (4) Y: Lu: Sc: V = 0: 1: 0: 1, corresponding to a = 0, b = 1, c = 0, bismuth replaces 3.00% of Lu, that is, d% = 3.00%;

[0049] (5) Y: Lu: Sc: V = 0: 1: 0: 1, corresponding to a = 0, b = 1, c = 0, bismuth replaces 5.00% of Lu, that is, d% = 5.00%;

[0050] (6) Y: Lu: Sc: V = 0: ...

Embodiment 3

[0055] Select yttrium nitrate, lutetium nitrate, scandium nitrate, vanadium oxide, bismuth subcarbonate as starting compound raw materials, press Y a Lu b sc c VO 4 : The molar ratio of the elements shown in d%Bi, respectively weigh five kinds of compound raw materials, a total of 1 group, the specific ratio is as follows: Y:Lu:Sc:V=1:0:0:1, corresponding to a=1, b=0, c=0, bismuth replaces 2.00% of Y, that is, d%=2.00%; the total weight of the control mixture is 5 grams. After grinding and mixing 5 grams of the mixture, put it into a corundum crucible, and then put the crucible into a high-temperature electric furnace. Precisely controlling the heating rate, the sample was pre-fired at 500°C for 5 hours. Take out the pre-fired sample, grind and mix it again, put it into a crucible, burn it at 900°C for 15 hours under oxygen, take it out and grind it again, burn it at 900°C for 15 hours under oxygen, and cool it naturally with the furnace , that is, bismuth-doped fluoresce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com