Process for preparing medical vaseline by hydrogenation with noble metal catalyst through two-stage method

A technology of precious metal catalysts and petrolatum, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, refined hydrocarbon oil, etc., and can solve problems such as increased equipment investment and operating costs, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

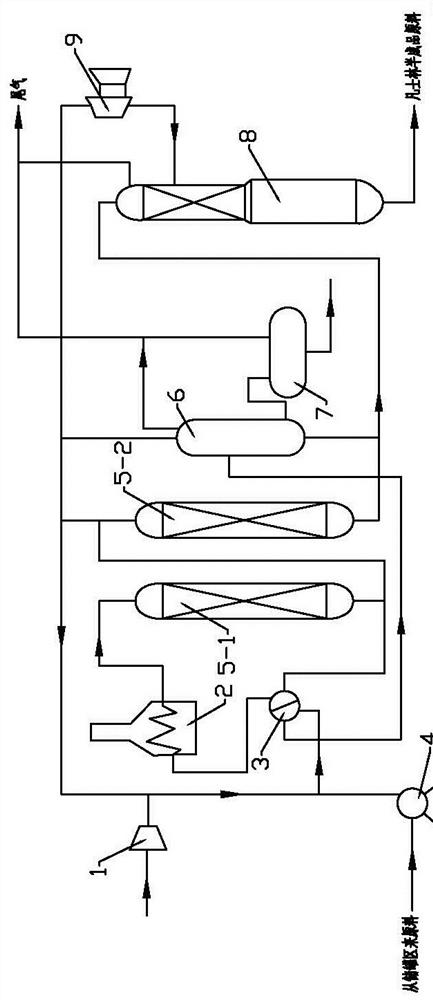

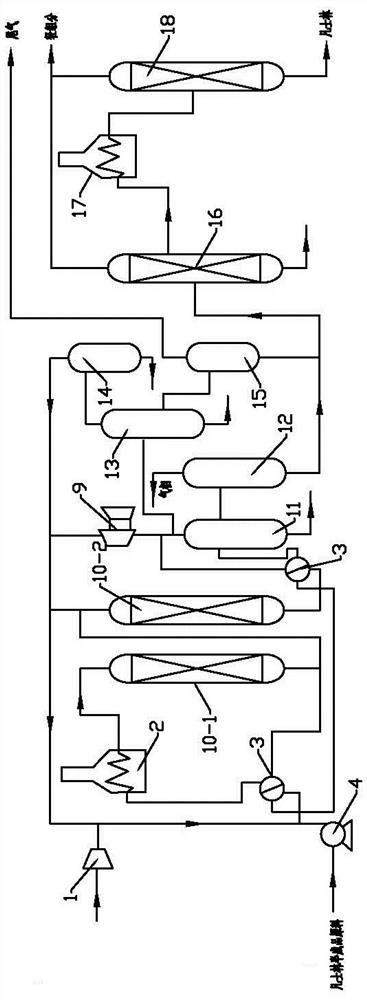

Method used

Image

Examples

Embodiment 1

[0066] The vaseline raw material heated to a certain temperature by the heating furnace 2 is mixed with hydrogen, and the mixture first enters the first-stage reactor. Under the pretreatment catalyst condition, the reaction temperature of the first-stage reactor is controlled to be 300°C, and the hydrogen partial pressure is 10MPa. The liquid hourly volume space velocity is 1.5h -1 , the volume ratio of hydrogen to oil is 500; the reaction product from the first-stage reactor is cooled by heat exchange, and then directly enters the second-stage reactor. Partial pressure is 10MPa, liquid hourly volume space velocity is 1 h -1 , the volume ratio of hydrogen to oil is 300; the reaction product from the second stage reactor is separated from gas and liquid, and the vaseline product is obtained after liquid phase stripping.

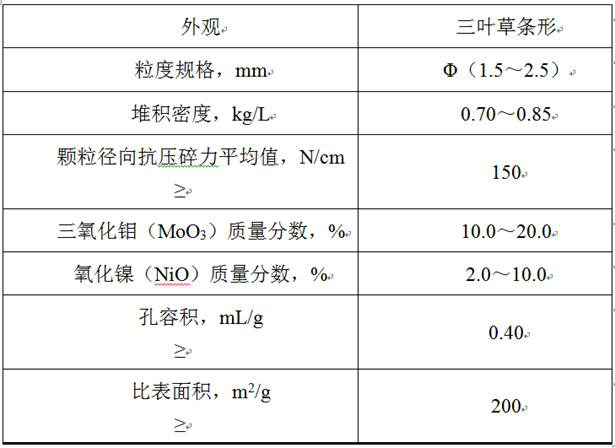

[0067] The pretreatment catalyst contains WO 3 22.5%, MoO 37.4%, NiO5.1%, the carrier is Al 2 o 3 ; The active component of the noble metal catalyst is P...

Embodiment 2

[0071] The vaseline raw material heated to a certain temperature by the heating furnace 2 is mixed with hydrogen, and the mixture first enters the first-stage reactor. Under the pretreatment catalyst condition, the reaction temperature of the first-stage reactor is controlled to be 250°C, and the hydrogen partial pressure is 15MPa. The liquid hourly volumetric space velocity is 0.1h -1 , the volume ratio of hydrogen to oil is 1500; the reaction product from the first-stage reactor is cooled by heat exchange, and then directly enters the second-stage reactor. Partial pressure is 16MPa, liquid hourly volume space velocity is 0.1h -1 , the volume ratio of hydrogen to oil is 1300; the reaction product from the second stage reactor is separated from gas and liquid, and the vaseline product is obtained after liquid phase stripping.

[0072] The pretreatment catalyst contains WO 3 22.5%, MoO 3 7.4%, NiO5.1%, the carrier is Al 2 o 3 -SiO 2 ; The active component of the noble met...

Embodiment 3

[0076] The vaseline raw material heated to a certain temperature by the heating furnace 2 is mixed with hydrogen, and the mixture first enters the first-stage reactor. Under the pretreatment catalyst condition, the reaction temperature of the first-stage reactor is controlled to be 400°C, and the hydrogen partial pressure is 5MPa. The liquid hourly volumetric space velocity is 0.1h -1 , the volume ratio of hydrogen to oil is 600; the reaction product from the first-stage reactor is cooled by heat exchange, and then directly enters the second-stage reactor. Partial pressure is 5MPa, liquid hourly volume space velocity is 1.5h -1 , the volume ratio of hydrogen to oil is 600; the reaction product from the second stage reactor is separated from gas and liquid, and the vaseline product is obtained after liquid phase stripping.

[0077] The pretreatment catalyst contains WO 3 22.5%, MoO 3 7.4%, NiO5.1%, the carrier is Al 2 o 3 ; The active component of the noble metal catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com