Method and device for improving number of electrostatic spinning multiple jet flows

An electrospinning and multi-jet technology, which is applied in the direction of spinning solution preparation, textile and papermaking, filament/thread forming, etc., can solve the problems of low fiber output and low efficiency of nanofiber preparation, and achieve high output and industrial implementation Easy, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

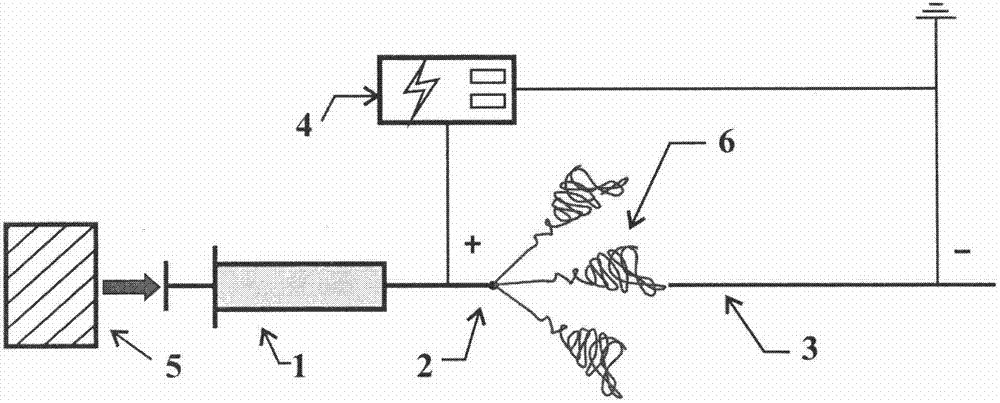

[0051] Design a device to improve the multi-jet flow of electrospinning, including liquid storage device 1, syringe pump 5, spinneret 2, metal needle 3, such as figure 1 shown. Wherein the metal needle 3 has a length of 10 cm, a diameter of 0.5 mm, and a hollow structure. The syringe pump 5, the liquid storage device 1, and the spinneret 2 are connected, the metal needle 3 is placed in a position in line with the spinneret 2, and the distance between the tip of the spinneret and the tip of the metal needle is 3 cm.

[0052] Before spinning, take by weighing 14 grams of polyvinyl alcohol polymer powder earlier, and mix with mixed solvent (distilled water and dehydrated alcohol mix with the mass ratio of 1: 1) with the mass ratio concentration of 14%, water bath heating (80 ℃ ) after 3-4 hours, let it stand for two hours to obtain polyvinyl alcohol spinning solution; then put the configured polyvinyl alcohol solution into the liquid storage device 1, connect the liquid storage ...

Embodiment 2

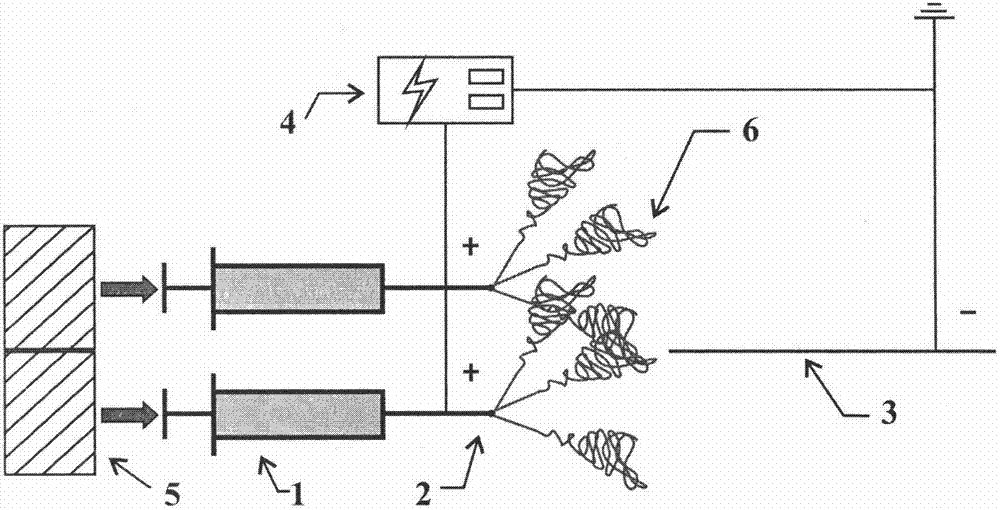

[0054] This embodiment adopts the same device as that of Embodiment 1, such as figure 2 shown.

[0055] Before spinning, weigh 34 grams of high molecular polymer—polyvinylpyrrolidone (model: k-30) powder, and mix it with a mixed solvent (distilled water and absolute ethanol are mixed in a mass ratio of 1:9) with 34% The mass ratio concentration is mixed, after stirring evenly, let stand for 2 hours to obtain polyvinylpyrrolidone spinning solution; then the configured polyvinylpyrrolidone solution is put into the liquid storage device 1, and the liquid storage device 1 and the syringe pump 5 The liquid storage device 1 is connected with the spinneret 2 through a catheter. Ensure that the syringe pump 5, the liquid storage device 1, and the spinneret 2 are well sealed. The positive pole of the electrostatic generator 4 is connected to the spinneret 2, and the negative pole is grounded; both the cylinder 7 and the metal needle 3 are grounded. The distance l between the metal ...

Embodiment 3

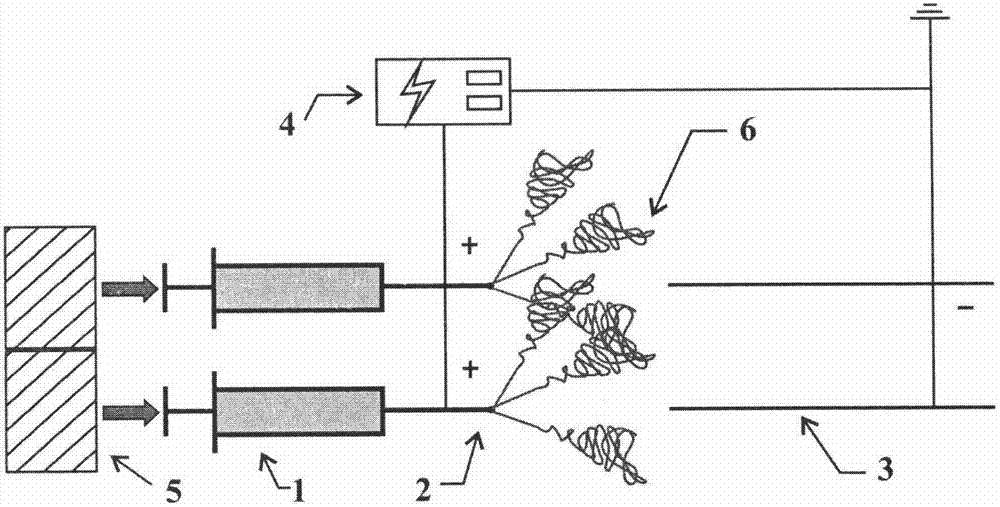

[0057] This embodiment adopts basically the same device and process as Implementation 1, and the change is that a spinneret 2 and a liquid storage device 1 are added, such as image 3 shown.

[0058] Before spinning, weigh 20 grams of high-molecular polymer-polyacrylonitrile powder, and mix it with the solvent dimethylformamide at a mass ratio concentration of 12%, heat it in a water bath (50° C.) for 3-4 hours, and let it stand After two hours, the polyacrylonitrile spinning solution was prepared; then the configured polyacrylonitrile solution was loaded into the liquid storage device 1, and each liquid storage device 1 was connected to the syringe pump 5, and the liquid storage device 1 was connected to the spinneret 2 Connected, the vertical distance between the two spinnerets 2 is 4cm. Ensure that the connection between the syringe pump 5, the liquid storage device 1 and the spinneret 2 is well sealed. The positive pole of the electrostatic generator 4 is connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com