Blade double-supporting variable-section nozzle ring assembly for bi-directional positioning of poking disc

A two-way positioning and dialing technology, applied in the field of auto parts, can solve the problems of jamming, deformation and movement, and the inability of the nozzle ring assembly to drive, and achieve the effect of preventing high temperature deformation and movement, and improving the stress condition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

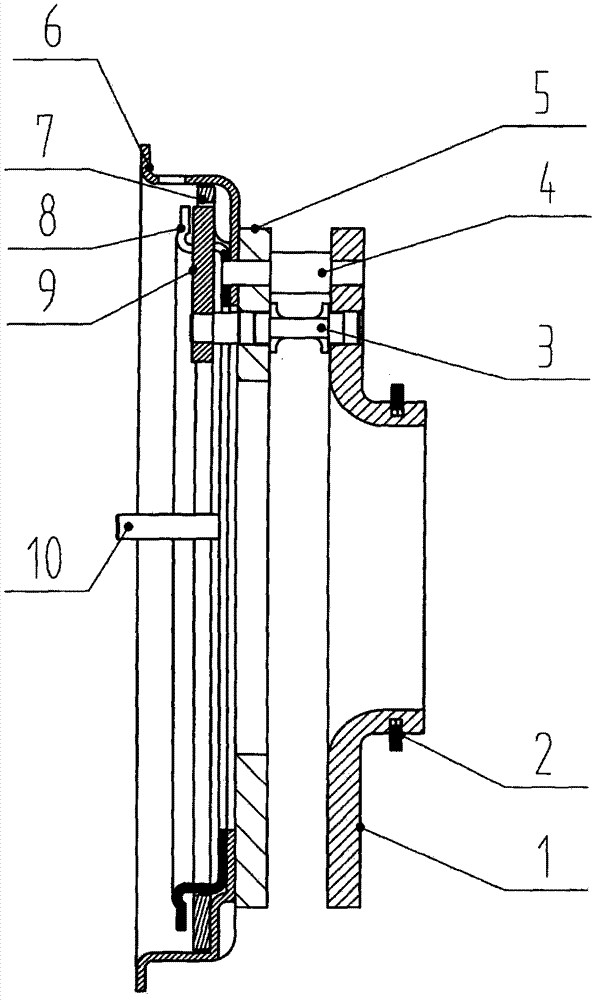

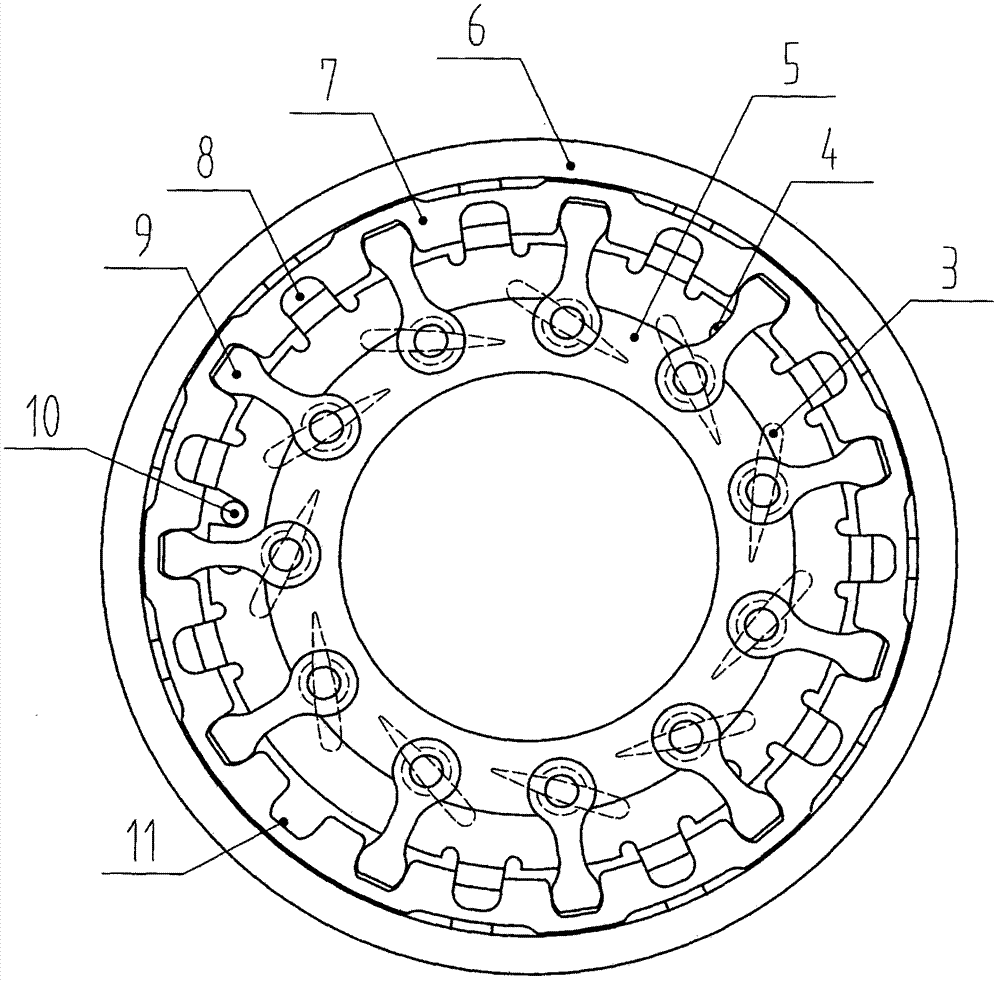

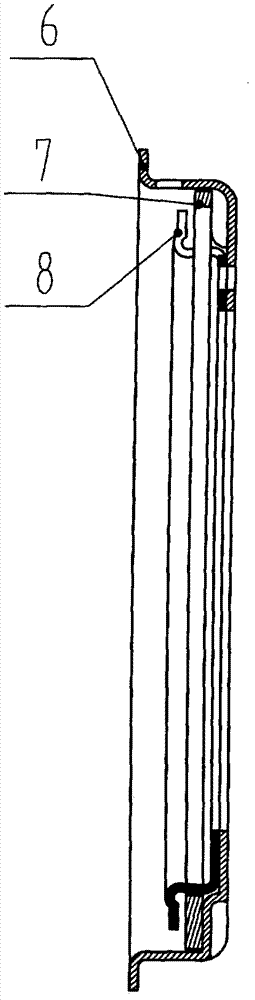

[0014] figure 2 It is embodiment 1 of the present invention, in figure 1 , figure 2 and image 3 Middle: The toggle plate 7 is placed in the limited space formed by the heat-insulating support plate 6 and the limit plate 8, and the heat-insulation support plate 6 and the limit plate 8 are welded on the mounting plate 5 through the distance sleeve 4, thereby turning The disk 7 is positioned axially and radially. In addition, the heat-insulating support disk 6 also plays a role of heat insulation, so that the temperature on the side of the shift fork 9 and the dial 7 is obviously lower than the temperature on the side of the blade 3 , to create a better working condition for the components, effectively preventing the high-temperature deformation and displacement of the dial 7; the dial 7 is provided with a notch 11 corresponding to the shift fork 9, and the shift fork 9 is directly placed on the dial 7 corresponding to the notch 11, can freely rotate and slide in the notch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com