led mirror light

A technology of LED light source and mirror, which is applied in the field of mirror lights, can solve the problems of low color purity, poor monochromaticity, and poor light effect, and achieve good color rendering, low power consumption, and good color purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

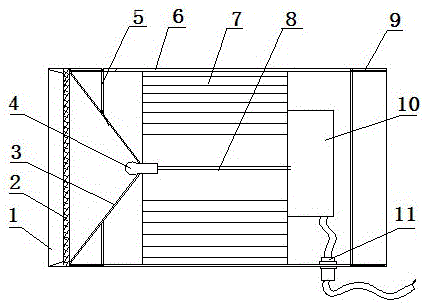

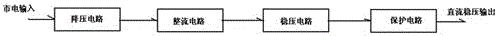

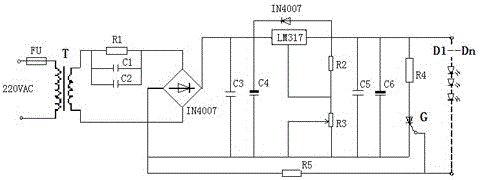

[0027] figure 1 As shown, the LED mirror lamp is composed of a mirror and a mirror lamp. The mirror lamp includes a light source, a lamp body, a power driver, a reflector, and an anti-glare board. In the middle of the shaped reflector, the reflector is fixed on the housing through a bracket. There is an anti-glare plate 2 in front of the LED light source 4, and a front cover 1 is outside the anti-glare plate 2. The LED light source 4 is pasted on the aluminum substrate 8 through silica gel. The aluminum substrate 8 is fixed on the heat sink 7, the driver 10 of the LED light source 4 provides a stable DC power supply, and is connected by a cable interface 11. There are rear end covers 9 at the front and rear of the lamp body.

[0028] The silica gel is compounded by metal oxides (iron oxide, titanium oxide) with good thermal conductivity and insulation properties and polysiloxane (polysiloxane, silicone). The product has excellent thermal conductivity, good electrical insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com