Process for designing refrigerating barrel (evaporator) of ice cream machine

An evaporator and ice cream technology, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of large weight of refrigeration cylinders, time-consuming cutting and processing, complex processes, etc., and achieve low production costs and easy quality of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The gist of the invention is

[0045] 1 Each fin is a separate ring structure, see Figure 5 .

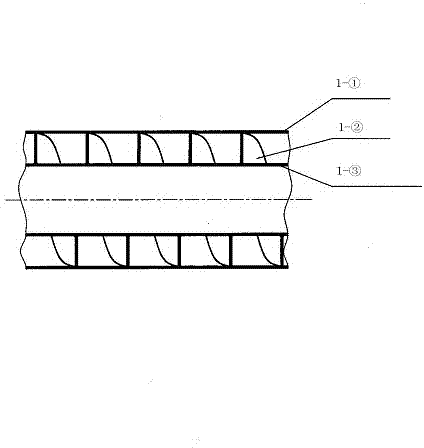

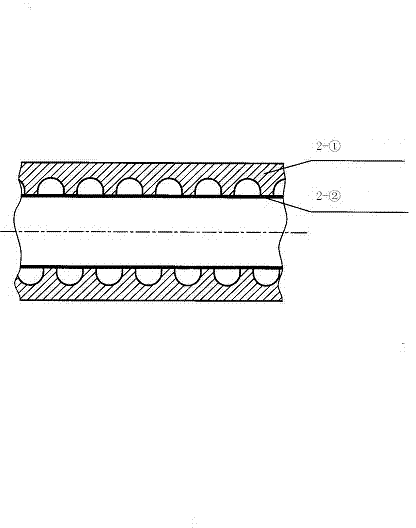

[0046] 2 The fins are stamped parts. After the fins are formed, the conical umbrella surface generatrix and the axis form an angle of 45 degrees. The fins are spaced one by one in the front and back (the openings of each adjacent fin are staggered by 180 degrees. ) is filled between the inner and outer shells of the refrigerating cylinder, and the space formed by two adjacent fins is used as the flow channel of the refrigerating medium (see Figure 6 ), after reaching the specified number, use the flanges at both ends to compress the fins, and use the triangular support section formed by the fins in the jacket to make the top and bottom circles of the fins fit closely with the outer shell and the inner cylinder respectively, and compact the two ends After the flange is welded and sealed.

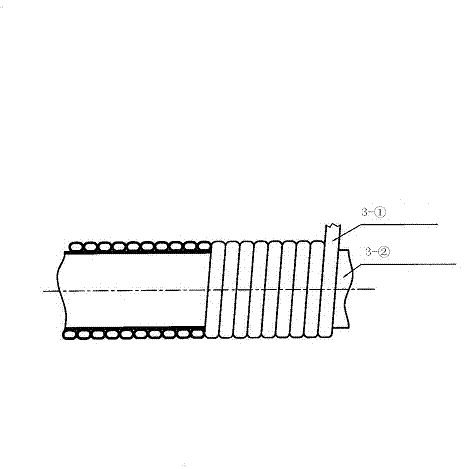

[0047] The design form of the fin can also adopt the second embodiment ( Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com