Ranking cycle cold source device and vacuum breakdown self diagnosis method

A technology of cold source device and Rankine cycle, which is applied in the field of failure detection of Rankine cycle cold source device, and can solve the problem that the cycle cold source device cannot perform vacuum fault self-test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

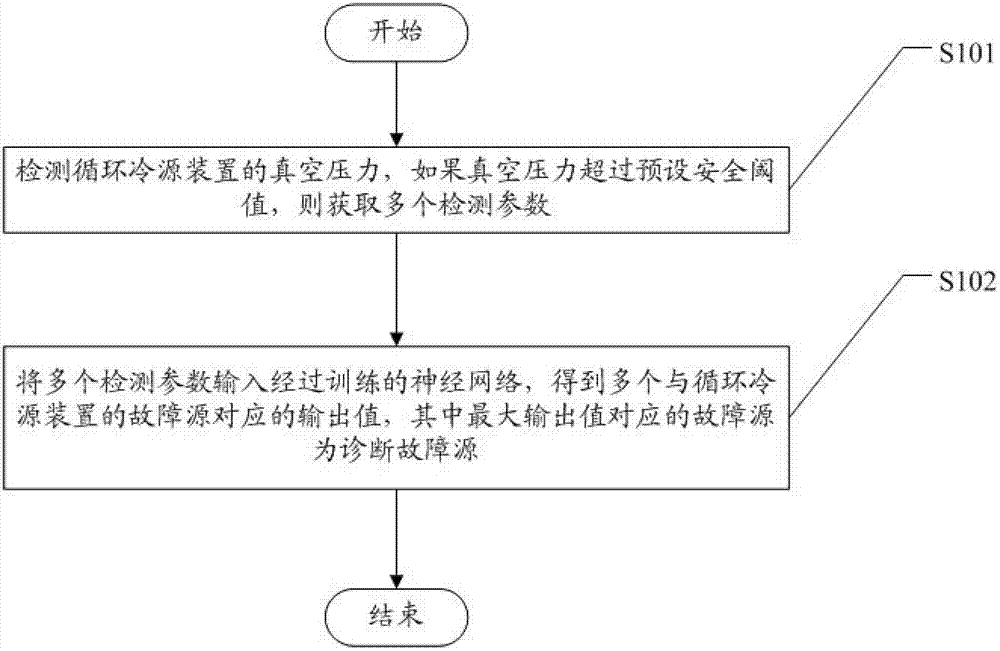

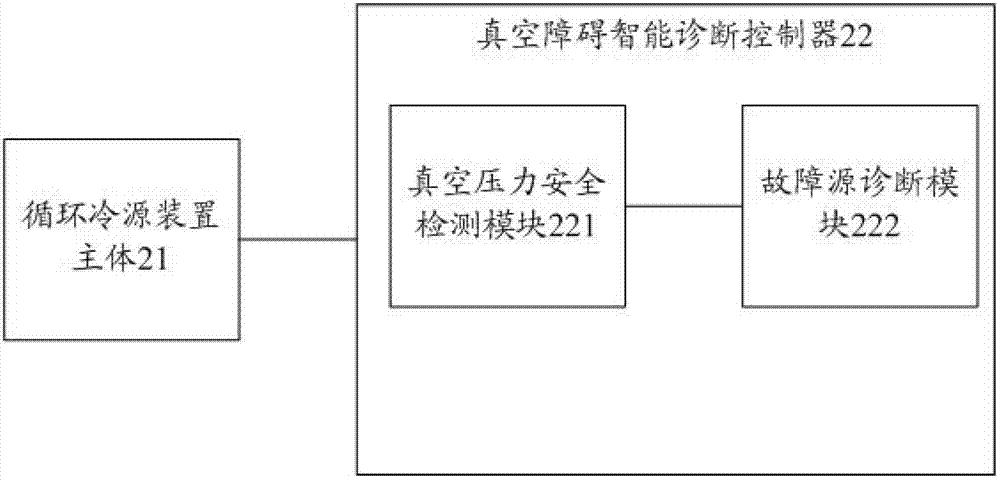

[0058] Such as figure 1 Shown is a working flow diagram of a vacuum fault self-diagnosis method for a circulating cold source device of the present invention, including:

[0059] Step S101, detecting the vacuum pressure of the circulating cold source device, if the vacuum pressure exceeds the preset safety threshold, obtaining multiple detection parameters;

[0060] Step S102, input multiple detection parameters into the trained neural network to obtain multiple output values corresponding to the fault sources of the circulating cold source device, wherein the fault source corresponding to the maximum output value is the diagnostic fault source.

[0061] Those of ordinary skill in the art can apply the vacuum fault self-diagnosis method of the circulating cold source device of the present invention to various circulating cold source device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com