Preparation method of Pd-nanoparticle-modified porous ZnO nanosheet gas-sensitive material and gas sensor

A technology of nano-particles and gas-sensing materials, which is applied in the field of preparation of new composite nano-gas-sensing materials and gas-sensing elements, which can solve problems such as low sensitivity, high operating temperature, and unsatisfactory operating temperature, and achieve high sensitivity and selectivity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

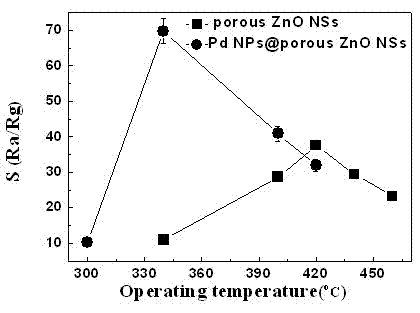

Embodiment 1

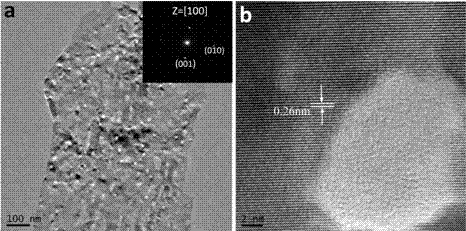

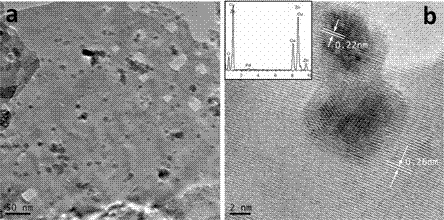

[0027] The prepared porous ZnO nanosheets were mixed with Pd nanoparticles, the content of Pd nanoparticles was 0.5%, ground in an agate mortar for 1 h, and calcined at 600 °C for 2 h to make a composite material of Pd nanoparticles modified ZnO. Then, the material was made into a slurry in terpineol, uniformly coated on the surface of the ceramic tube, then dried in an oven at 100°C for 1 h, then put into a muffle furnace for calcination at 540°C for 2 h, and then followed by Side heating conventional process, welding, packaging, aging, made of gas sensor. The gas sensitivity test results show that its sensitivity to 100 ppm acetone vapor is as high as 70, and the sensitivity to 500 ppm reaches 222, and the response-recovery time is 7 s and 8 s, respectively. Figure 4 shown.

Embodiment 2

[0029] The prepared porous ZnO nanosheets were mixed with Pd nanoparticles, the content of Pd nanoparticles was 0.4%, ground in an agate mortar for 30min, and calcined at 550°C for 1.5h to make a composite material of Pd nanoparticles modified ZnO. A slurry is made, evenly coated on the surface of the ceramic tube, then dried in an oven at 80°C for 1 hour, then placed in a muffle furnace for calcination at 560°C for 1.5 hours, and then welded, packaged, Aging, made of gas sensor. The gas sensitivity test results show that its sensitivity to 100 ppm acetone vapor is as high as 71, and the sensitivity to 500 ppm reaches 216, and the response-recovery time is 8 s and 9 s, respectively.

Embodiment 3

[0031] The prepared porous ZnO nanosheets were mixed with Pd nanoparticles, the content of Pd nanoparticles was 0.3%, ground in an agate mortar for 40min, and calcined at 550°C for 1h to make a composite material of Pd nanoparticles modified ZnO. The material was made into a slurry in terpineol, evenly coated on the surface of the ceramic tube, then dried in an oven at 90 °C for 1 h, then put into a muffle furnace for calcination at 500 °C for 1.8 h, and then followed by the side heating method Conventional process, welding, packaging, aging, made of gas sensor. The gas sensitivity test results show that its sensitivity to 100 ppm acetone vapor is as high as 68, and the sensitivity to 500 ppm reaches 209, and the response-recovery time is 10 s and 10 s, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com