Method for emptying solvent from liquid chromatography and gas chromatography on-line coupling interface

A gas chromatography and liquid chromatography technology, applied in the field of solvent evacuation, can solve the problems of shutdown, mass spectrometer alarm, solvent entering the analytical column and detector, etc., and achieve the effect of reducing pollution and speeding up the purification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

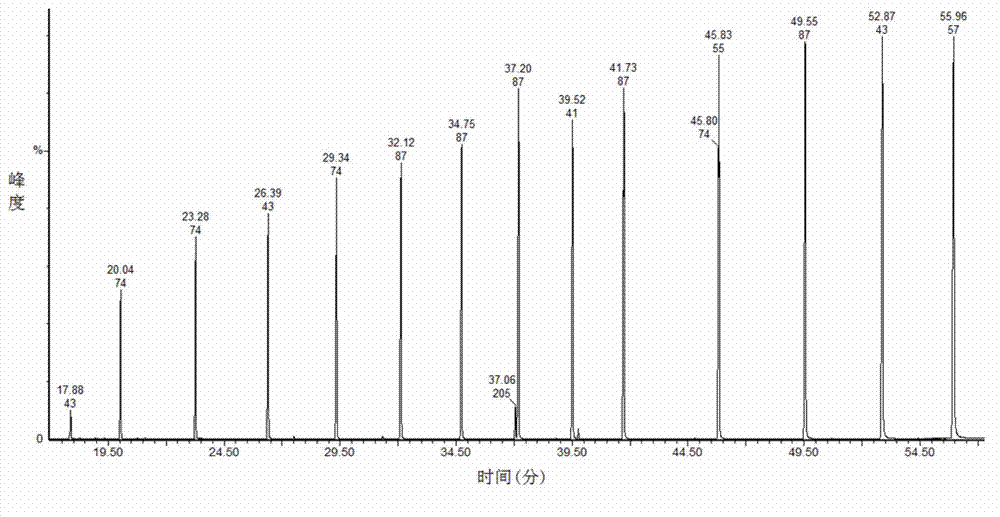

Examples

Embodiment Construction

[0023] The technical solutions of the present invention are illustrated below through specific examples. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. Moreover, unless otherwise stated, changes or adjustments to the technical content by those skilled in the art shall also be considered as the scope of the present invention if there is no substantial change in the technical content.

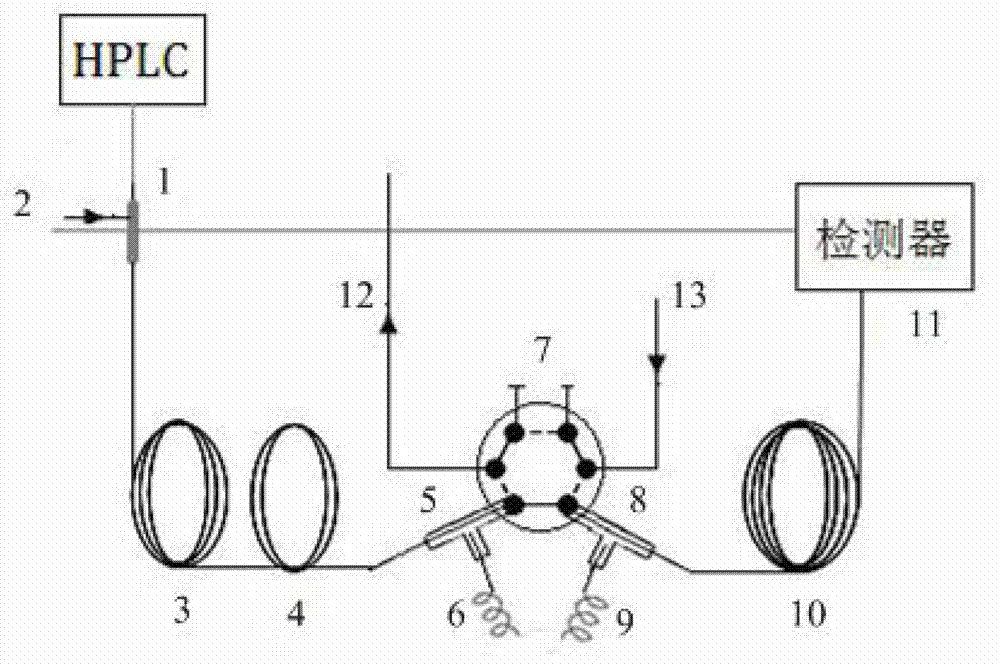

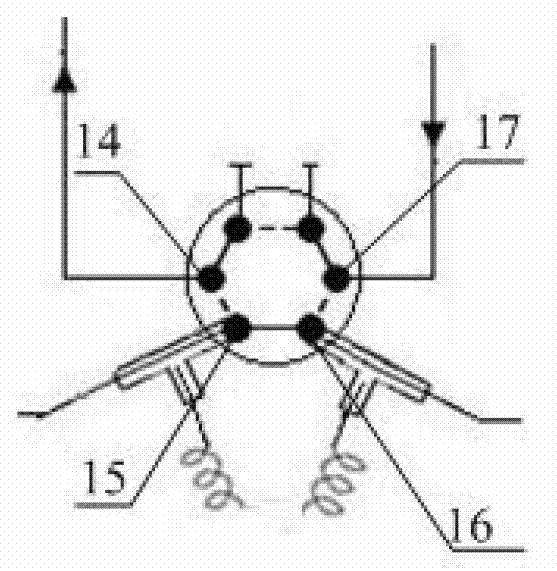

[0024] A solvent evacuation method for a liquid chromatography-gas chromatography online interface, for connecting a solvent evacuation device between the retention pre-column 4 and the gas chromatographic separation column 10 of the gas chromatograph; the solvent evacuation device, Such as figure 2 As shown, it includes two three-way joints 5 , 8 and a two-position switching valve 7 connected between the two three-way joints 5 , 8 .

[0025] The two ends of one of the three-way join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com