Method for preparing composite nano material filled with lithium iron phosphate between graphene layers

A composite nanomaterial, lithium iron phosphate technology, applied in the field of positive electrode materials of lithium ion batteries, can solve the problems of many steps, complicated processes, unreported graphene/lithium iron phosphate composite nanomaterials, etc., achieves good dispersibility, improves The effect of charging and discharging performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

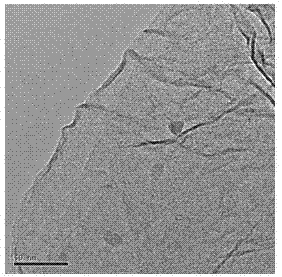

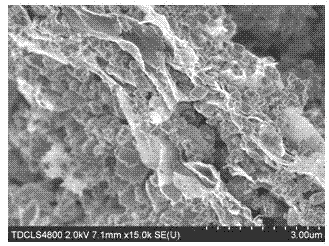

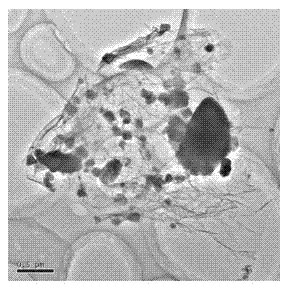

Image

Examples

Embodiment 1

[0023] 0.02 g of graphene was added to 20 mL of ethylene glycol, and 0.02 g of tris-sulfopropyl tetradecyl dimethyl betaine was added at the same time, and sonicated at room temperature for 1 h. 0.34855 g of ammonium dihydrogen phosphate and 0.8425 g of ferrous sulfate heptahydrate were weighed and added to the above solution, and then magnetic stirring was continued for 10 min at room temperature. Weigh 0.37764g of lithium hydroxide monohydrate, dissolve it in 15mL of ethylene glycol, add it dropwise to the above solution with a dropper at a rate of 15 drops / min after dissolving, and continue magnetic stirring for 3 hours to obtain the precursor mixture. The precursor mixed solution was ultrasonically stirred for 30 minutes at room temperature, then magnetically stirred at room temperature for 30 minutes, and then the resulting mixed solution was quickly placed in a high-pressure reactor, reacted at 200 ° C for 10 h, cooled at room temperature, filtered, washed, and heated at...

Embodiment 2

[0025] 0.01 g of graphene was added to 20 mL of ethylene glycol, and 0.01 g of tris-sulfopropyl tetradecyl dimethyl betaine was added at the same time, and the mixture was sonicated for 1 h at room temperature. Weighed 0.34855g of ammonium dihydrogen phosphate and 0.8425g of ferrous sulfate heptahydrate were added to the above solution, and then continued to stir at room temperature. Weigh 0.37764g of lithium hydroxide monohydrate, dissolve it in 15mL of ethylene glycol, add dropwise to the above solution with a dropper at a rate of 15 drops / min after dissolving, and continue to stir for 3 hours to obtain the precursor mixture solution. The precursor mixed solution was ultrasonicated for 30 minutes at room temperature and then stirred at room temperature for 30 minutes, then the resulting mixed solution was quickly placed in a high-pressure reactor, reacted at 200 ° C for 10 h, filtered and washed after cooling at room temperature, and vacuumed at 80 ° C Dry in a drying oven ...

Embodiment 3

[0027] Add 0.08 g of graphene into 20 mL of ethylene glycol, and at the same time add 0.08 g of tris-sulfopropyl tetradecyl dimethyl betaine, and sonicate at room temperature for 1 h. Weighed 0.34855g of ammonium dihydrogen phosphate and 0.8425g of ferrous sulfate heptahydrate were added to the above solution, and then continued to stir at room temperature. Weigh 0.37764g of lithium hydroxide monohydrate, dissolve it in 15mL of ethylene glycol, add dropwise to the above solution with a dropper at a rate of 15 drops / min after dissolving, and continue to stir for 3 hours to obtain the precursor mixture solution. The precursor mixed solution was ultrasonicated for 30 minutes at room temperature and then stirred at room temperature for 30 minutes, then the resulting mixed solution was quickly placed in a high-pressure reactor, reacted at 200 ° C for 10 h, filtered and washed after cooling at room temperature, and vacuumed at 80 ° C Dry in a drying oven for 10 hours. Grind the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com