Semiconductor laser emitting from vertical and extended cavity surface used for electric pump

A laser, electric pumping technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of high technical difficulty, damage to the active area of the device, non-compliance, etc., achieve high output power, low series resistance, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

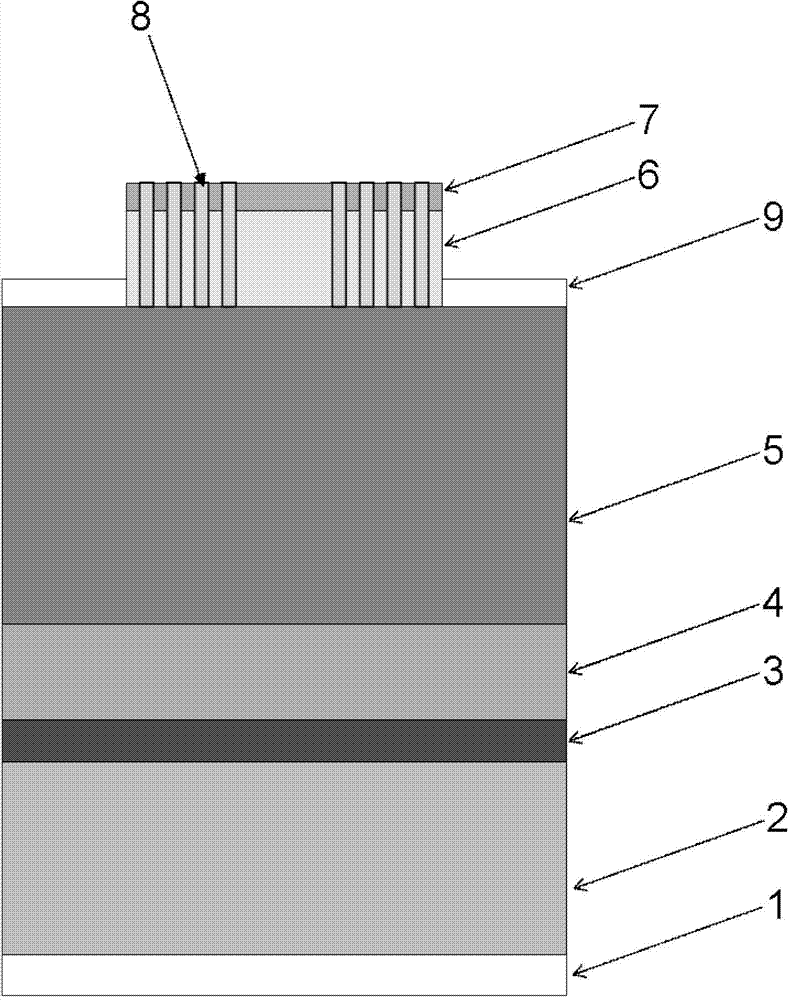

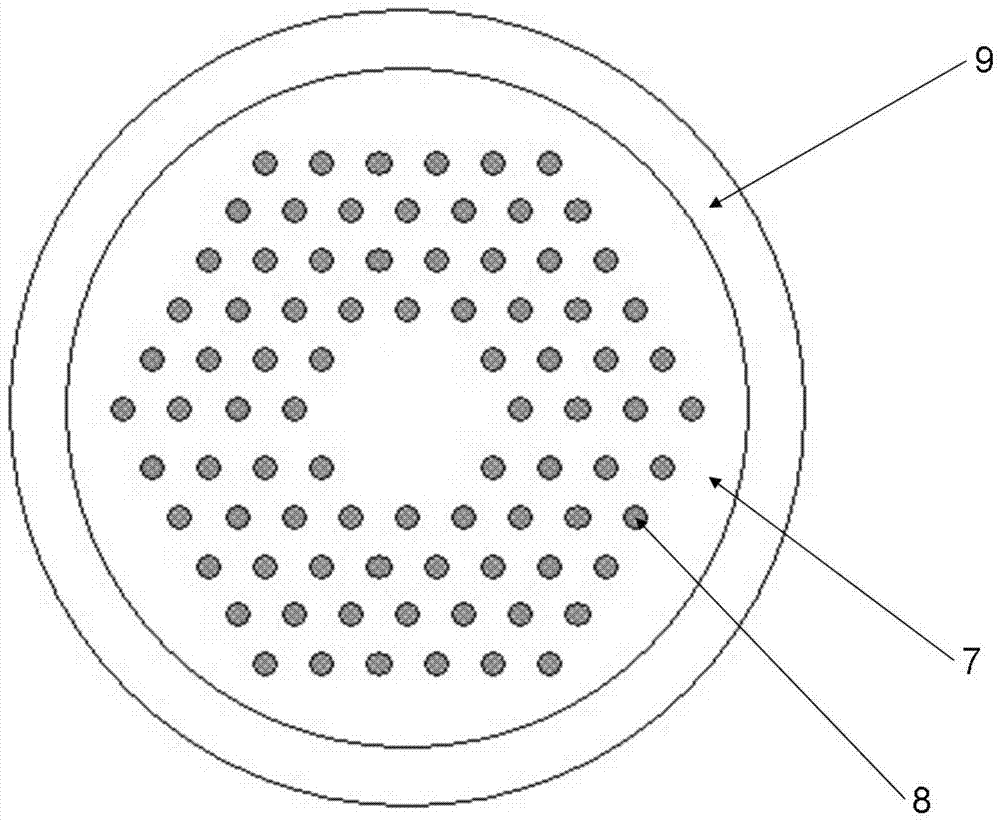

[0033]For the output light with a lasing wavelength of 980nm, the active layer 3 is a continuous laser power supply, the P-type DBR layer 2 is 20 pairs of AlGaAs / GaAs, the first N-type DBR layer 4 is 10 pairs of AlGaAs / GaAs, and the substrate layer 5 is GaAs , the second N-type DBR layer 6 is 20 pairs of AlGaAs / GaAs, the epitaxial anti-reflection layer 7 is a group of AlAs thin films with stepwise changes in Al composition, and a dry method is used on the epitaxial anti-reflection layer 7 and the second N-type DBR layer 6 The photonic crystal defect microcavity structure 8 with a periodic structure is produced by etching technology, the active layer 3 is a periodic InGaAs / GaAsP multi-quantum well structure, including InGaAs quantum wells and GaAsP barriers, and the lower electrode 1 is 10 pairs of Ti / The Au metal thin film, the upper electrode 9 is an AuGeNi / Au thin film, so that a 980nm electrically pumped vertically extended cavity surface-emitting semiconductor laser can be...

Embodiment 2

[0035] The material of the P-type DBR layer 2 in Example 1 is changed to InP / InGaAsP, and the logarithm is changed to 40 pairs. The material of the first N-type DBR layer 4 is changed to InP / InGaAsP, and the logarithm is changed to 20 pairs. The second N-type The material of DBR layer 6 is changed to InP / InGaAsP, the logarithm is changed to 40 pairs, the active layer 3 is changed to a periodic InGaAsP / InP multi-quantum well structure, the material of substrate layer 5 is changed to InP material, the bottom electrode 1, and the epitaxial anti-reflection layer 7. The photonic crystal defect microcavity structure 8 with periodic structure and the upper electrode 9 remain unchanged, so that a 1550nm electrically pumped vertically extended cavity surface-emitting semiconductor laser can be obtained, and a high-power single transverse mode laser output in the 1550nm band can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com