Treatment method for avoiding yellowing of stannous methanesulfonate

A technology of stannous methanesulfonate and its treatment method, which is applied to the preparation of sulfonate, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of stannous methanesulfonate oxidation and yellowing, and improve the product quality. Quality, avoid yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

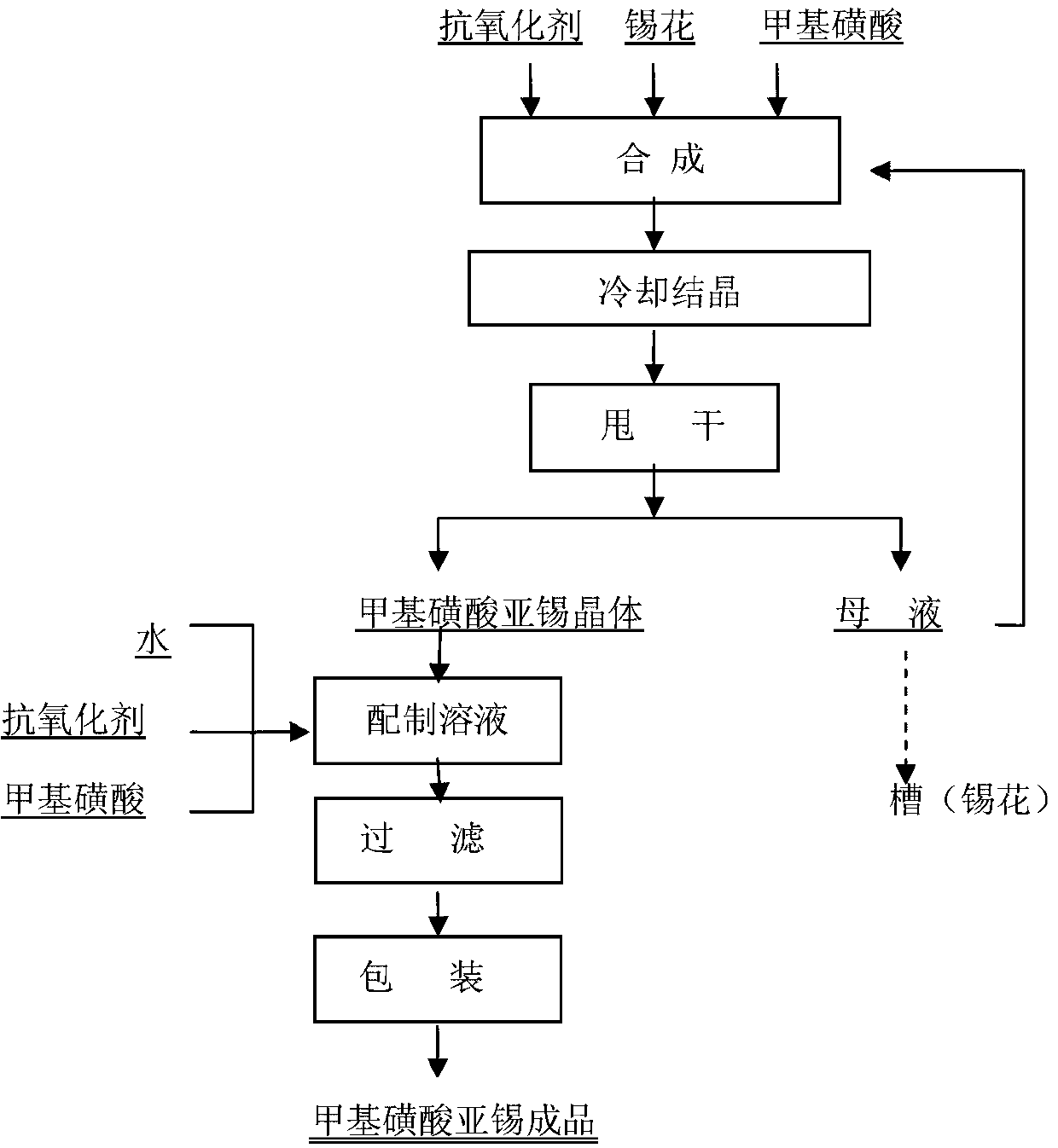

[0035] at 1.5m 3 Add 100kg tin flower, 400L 99% methanesulfonic acid, 50L mother liquor, and add 0.7kg hydroquinone to the reaction kettle, and stir, and react for 5h at a vacuum of 0.01MPa and a temperature of 110°C. The solution that reaction obtains is put in the crystallization jar, is cooled to room temperature, then the crystal that obtains is carried out centrifugal drying, obtains the stannous methanesulfonate crystal of 89kg, by W (CH3SO3)2Sn :W H2O :W CH3SO3H :W 抗氧化剂 =160:90:2:0.5 ratio is made into an aqueous solution, stirred and dissolved, filtered to obtain 50.3% stannous methanesulfonate, and packed to obtain a clear and transparent stannous methanesulfonate finished product, the finished product has no hair Yellow phenomenon; Simultaneously, the mother liquor after the crystallization returns in the described reactor and reacts.

Embodiment 2

[0037] at 1.5m 3 Add 100kg of tin powder, 400L of 99% methanesulfonic acid, 40L of mother liquor, add 0.7kg of hydroquinone, and stir, and react for 6h under the condition of vacuum degree of 0.015MPa and temperature of 140°C. The solution that reaction obtains is put in the crystallization tank, is cooled to room temperature, then the crystal that obtains is carried out centrifugal drying, obtains the stannous methanesulfonate of 80kg to carry out, press W (CH3SO3)2Sn :W H2O :W CH3SO3H :W 抗氧化剂 The ratio of =160:90:3:0.85 is made into an aqueous solution, stirred and dissolved, filtered to obtain 51.8% stannous methanesulfonate product, and packaged to obtain a clear and transparent stannous methanesulfonate finished product, which has no Yellowing phenomenon; at the same time, the mother liquor after crystallization is put into the groove that tin flower is housed.

Embodiment 3

[0039] at 1.5m 3 Add 100kg of tin particles, 400L of 99% methanesulfonic acid, 60 L of mother liquor, add 0.7kg of hydroquinone, stir, and react for 10h at a vacuum of 0.02MPa and a temperature of 180°C. The solution that reaction obtains is put in the crystallization jar, is cooled to room temperature, then the crystal that obtains is carried out centrifugal drying, obtains the stannous methanesulfonate crystal of 73kg, by W (CH3SO3)2Sn :W H2O :W CH3SO3H :W 抗氧化剂 The ratio of =160:90:4:1 is made into an aqueous solution, stirred and dissolved, filtered to obtain 50.6% stannous methanesulfonate product, and packaged to obtain a clear and transparent stannous methanesulfonate finished product, which has no Yellowing phenomenon; Simultaneously, the mother liquor after the crystallization returns in the described reactor to react.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap