Preparation technology for tea polyphenol oxidized polymer with alpha-glucosidase inhibition effect

A technology of glucosidase and inhibition, which is applied in the field of preparation of tea polyphenol oxidation polymers, can solve the problems of insufficient cost of treatment of toxic and side effects, and achieve a good effect of α-glucosidase inhibitory activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

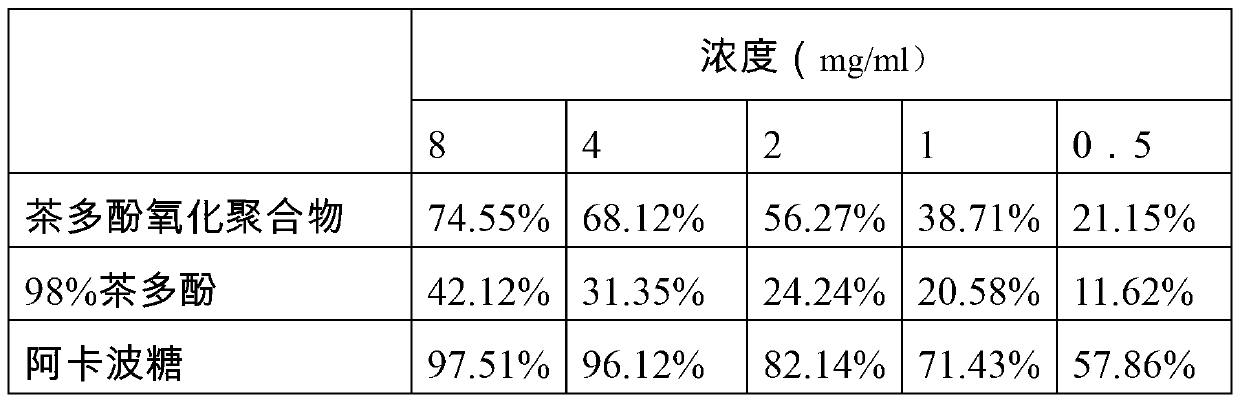

Embodiment 1

[0018] The raw materials used in this process are as follows:

[0019] Contains 98% tea polyphenol tea extract; food-grade laccase (5000U / g), food-grade laccase, that is, laccase that reaches the safety level of food grade; distilled water.

[0020] The reaction system includes: 1 g of tea polyphenols, 5 g of laccase, and 1000 mL of distilled water.

[0021] 1) Add 98% tea polyphenols in the corresponding weight portion into a beaker with a stirring bar, stir evenly on a constant temperature magnetic stirrer, and control the temperature at 60°C, and stir until it is in a clear and transparent liquid state;

[0022] 2) Add the corresponding weight of laccase into the beaker, and at the same time, pass oxygen into the beaker, stir evenly on a constant temperature magnetic stirrer, so that the laccase is evenly distributed in the beaker liquid, stir for about 10 minutes until it becomes a translucent liquid State, adjust pH5.5;

[0023] 3) Maintain the reaction temperature at 5...

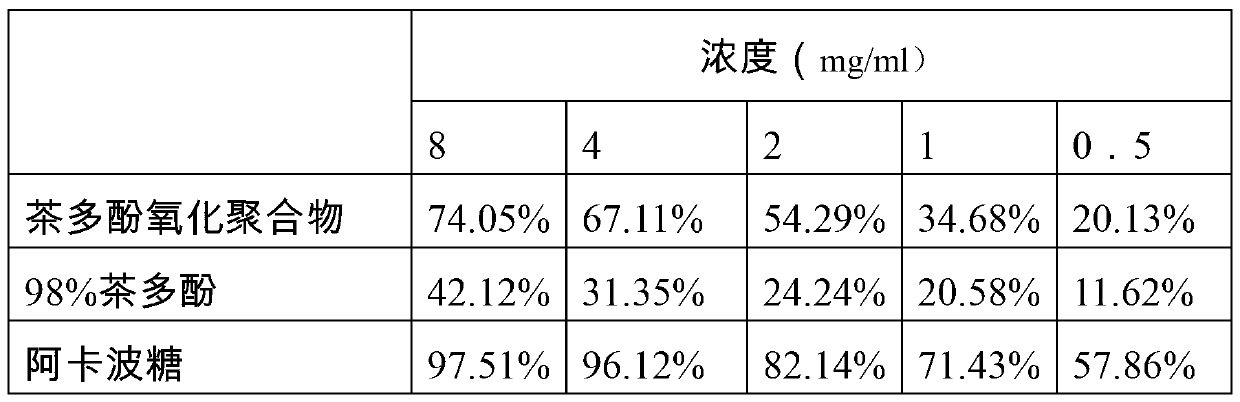

Embodiment 2

[0027] The raw materials used in this process are as follows:

[0028] Contains 98% tea polyphenol tea extract; food-grade laccase (5000U / g), food-grade laccase, that is, laccase that reaches the safety level of food grade; distilled water.

[0029] The reaction system includes: 1 g of tea polyphenols, 5 g of laccase, and 1000 mL of distilled water.

[0030] 1) Add 98% tea polyphenols in the corresponding weight portion into a beaker with a stirring bar, stir evenly on a constant temperature magnetic stirrer, and control the temperature at 60°C, and stir until it is in a clear and transparent liquid state;

[0031] 2) Add the corresponding weight of laccase into the beaker, and at the same time, pass oxygen into the beaker, stir evenly on a constant temperature magnetic stirrer, so that the laccase is evenly distributed in the beaker liquid, stir for about 10 minutes until it becomes a translucent liquid state;

[0032] 3) Maintain the reaction temperature at 55°C, react for...

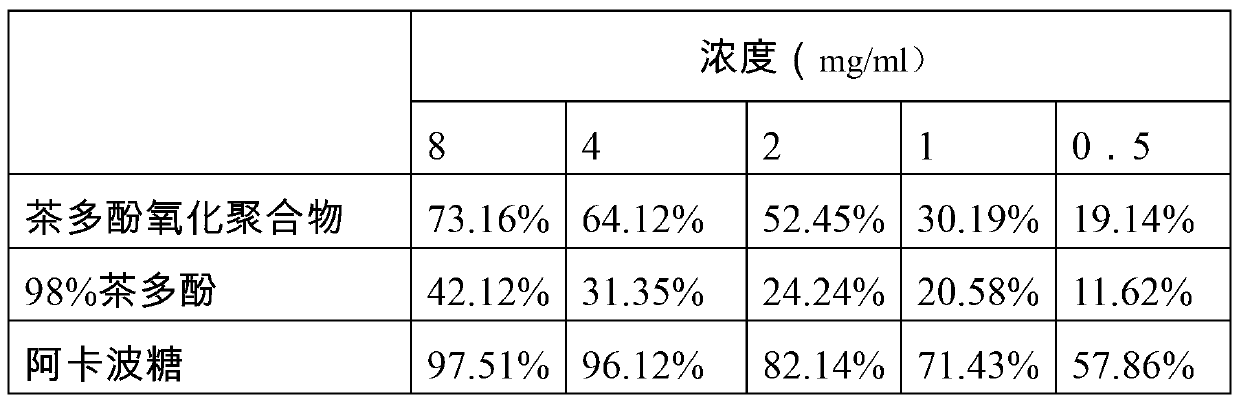

Embodiment 3

[0036] The raw materials used in this process are as follows:

[0037] Contains 98% tea polyphenol tea extract; food-grade laccase (5000U / g), food-grade laccase, that is, laccase that reaches the safety level of food grade; distilled water.

[0038] The reaction system includes: 1 g of tea polyphenols, 5 g of laccase, and 1000 mL of distilled water.

[0039] 1) Add 98% tea polyphenols in the corresponding weight portion into a beaker with a stirring bar, stir evenly on a constant temperature magnetic stirrer, and control the temperature at 60°C, and stir until it is in a clear and transparent liquid state;

[0040] 2) Add the corresponding weight of laccase into the beaker, and at the same time, pass oxygen into the beaker, stir evenly on a constant temperature magnetic stirrer, so that the laccase is evenly distributed in the beaker liquid, stir for about 10 minutes until it becomes a translucent liquid state;

[0041] 3) Maintain the reaction temperature at 60°C, react for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com