Toner for electrostatic latent image development and method of producing toner for electrostatic latent image development

An electrostatic latent image and toner technology, which is applied in the direction of developer, electrography, optics, etc., can solve the problems of poor image, charged toner, low image density, etc., and achieve the effect of suppressing bad image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

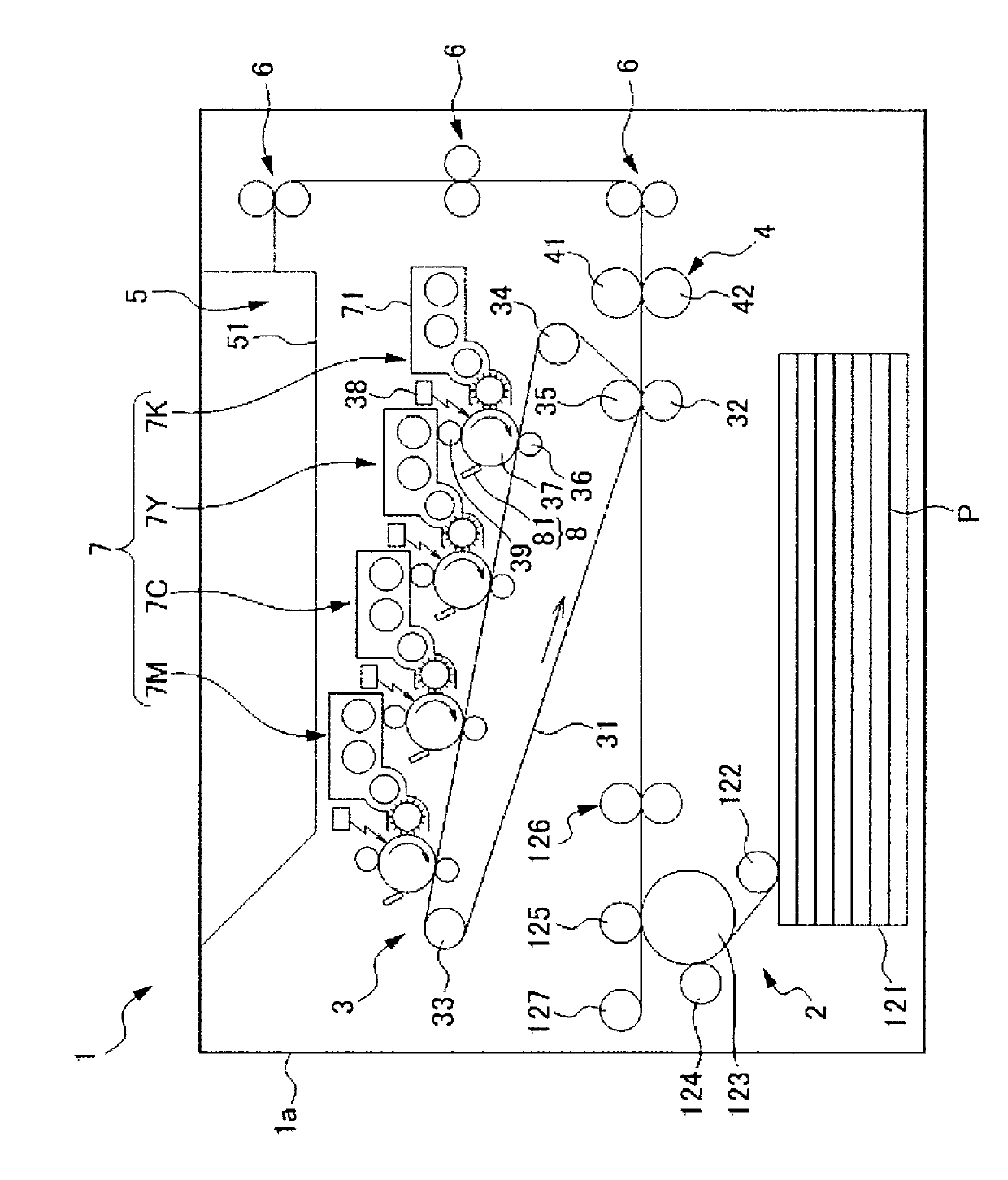

Image

Examples

preparation example Construction

[0057] [Manufacturing method of toner for electrostatic latent image development]

[0058] The toner for developing an electrostatic latent image of the present invention is a mixture of pulverized toner, a colorant, a charge control agent, a release agent, and, if necessary, components such as magnetic powder, mixed with a binder resin. After melt-kneading, the melt-kneaded product is pulverized and classified so as to have a desired particle size, thereby preparing it. The average particle diameter of the pulverized and classified toner is not particularly limited within a range that does not hinder the object of the present invention, but is usually preferably 5 μm or more and 10 μm or less.

[0059] As a preferred method of producing such toner particles, there is a method in which a binder resin, a colorant, a charge control agent, a release agent, and, if necessary, components such as magnetic powder are mixed with a mixer. , melt and knead the obtained mixture with a k...

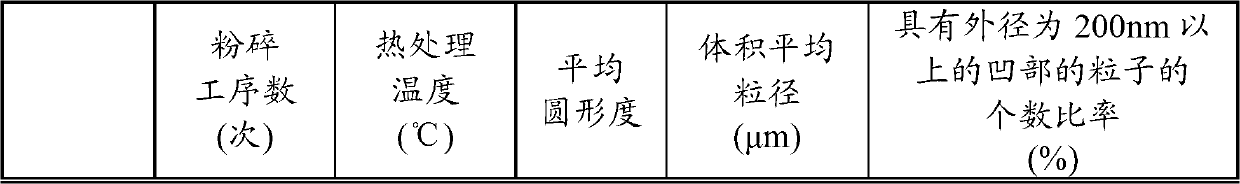

Embodiment

[0104] The present invention will be described more specifically by way of examples below. In addition, this invention is not limited to an Example.

preparation example 1

[0107]Add 1960g of propylene oxide adduct of bisphenol A, 780g of ethylene oxide adduct of bisphenol A, 257g of dodecenyl succinic anhydride, 770g of terephthalic acid and 4g of dibutyltin oxide to the reaction in the container. Next, the temperature in the reaction container was raised to 235° C. while stirring under a nitrogen atmosphere. Next, after carrying out reaction at this temperature for 8 hours, the inside of a reaction container was decompressed to 8.3 kPa, and reaction was carried out for 1 hour, and the reaction mixture was obtained. The reaction mixture was then cooled to 180°C and trimellitic anhydride was added to the reaction vessel to form the desired oxidation. Next, the temperature of the reaction mixture was raised to 210° C. at a rate of 10° C. / hour, and the reaction was carried out at this temperature. After completion of the reaction, the contents of the reaction container were taken out and cooled to obtain a polyester resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com