Sulfur hexafluoride high-voltage circuit breaker for cold region

A high-voltage circuit breaker and sulfur hexafluoride technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of reduced gas density, accelerated aging of sealing rings, high cost, etc., and achieve slow temperature reduction. , the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the technical solution of the present invention, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

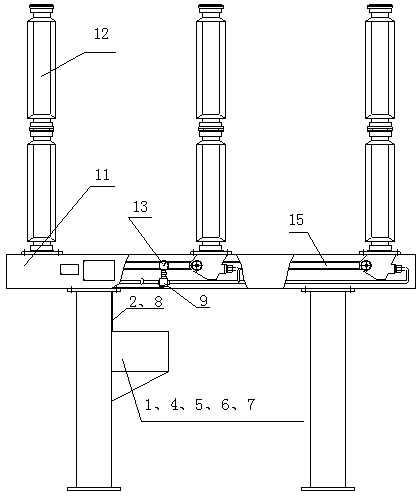

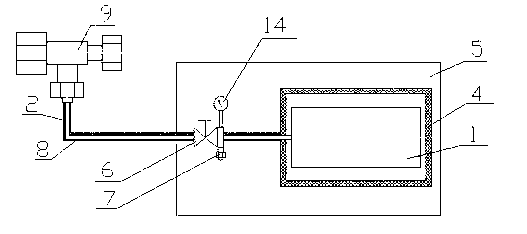

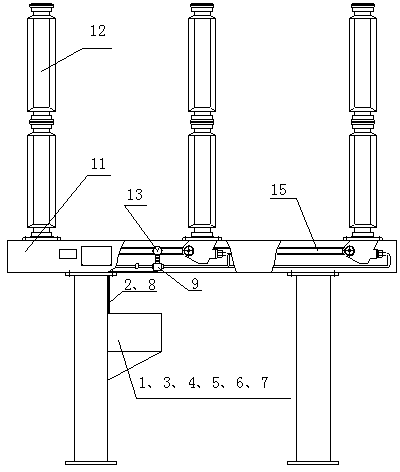

[0034] see figure 1 , figure 2 , the first sulfur hexafluoride high-voltage circuit breaker of the present invention includes a high-voltage circuit breaker body 11, a sulfur hexafluoride gas chamber 12 arranged in the high-voltage circuit breaker body, a density relay 13, a transmission mechanism 15, and a Sulfur gas liquefaction plant. The device for preventing the liquefaction of sulfur hexafluoride gas includes a sulfur hexafluoride gas storage tank 1, a connecting pipe 2, a heat insulating layer 4, a shell 5, a valve 6, a joint 7, and a heat insulating layer 8. Among them, the sulfur hexafluoride gas liquefaction device is installed next to the high-voltage circuit breaker. One end of the connecting pipe 2 is sealed and connected to the gas supply port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com