Manufacturing method for structure of wafer level light emitting diode matrix

A technology of light-emitting diodes and array structures, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of cumbersome and complicated processes, high yield requirements, and longer production cycles, and achieve simple operation, high yield, and The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

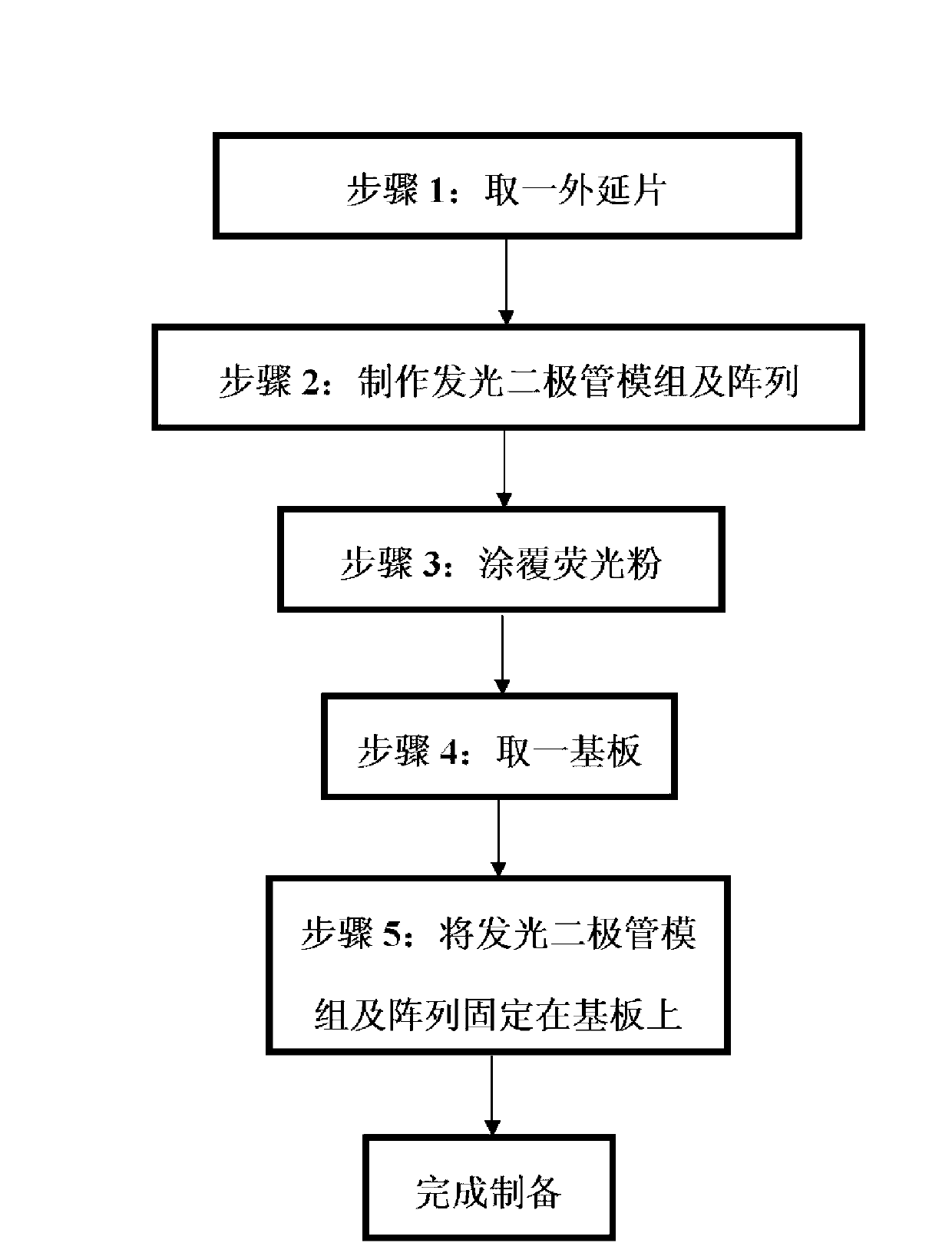

[0018] see Figure 1 to Figure 3 As shown, the present invention provides a method for preparing a wafer-level light-emitting diode array structure, comprising the following steps:

[0019] Step 1: Take an epitaxial wafer 10, and the material of the epitaxial wafer can be III-V group semiconductor material, such as GaAs, GaN and so on. Epitaxial materials can be obtained by vapor phase epitaxy or metal organic compound chemical vapor deposition techniques. Taking GaN materials as an example, epitaxial materials can be grown on sapphire, silicon carbide or silicon substrates, and the growth of epitaxial wafers can also be completed on GaN self-supporting substrates. The epitaxial wafer includes an n-type layer, an active layer and a p-type layer.

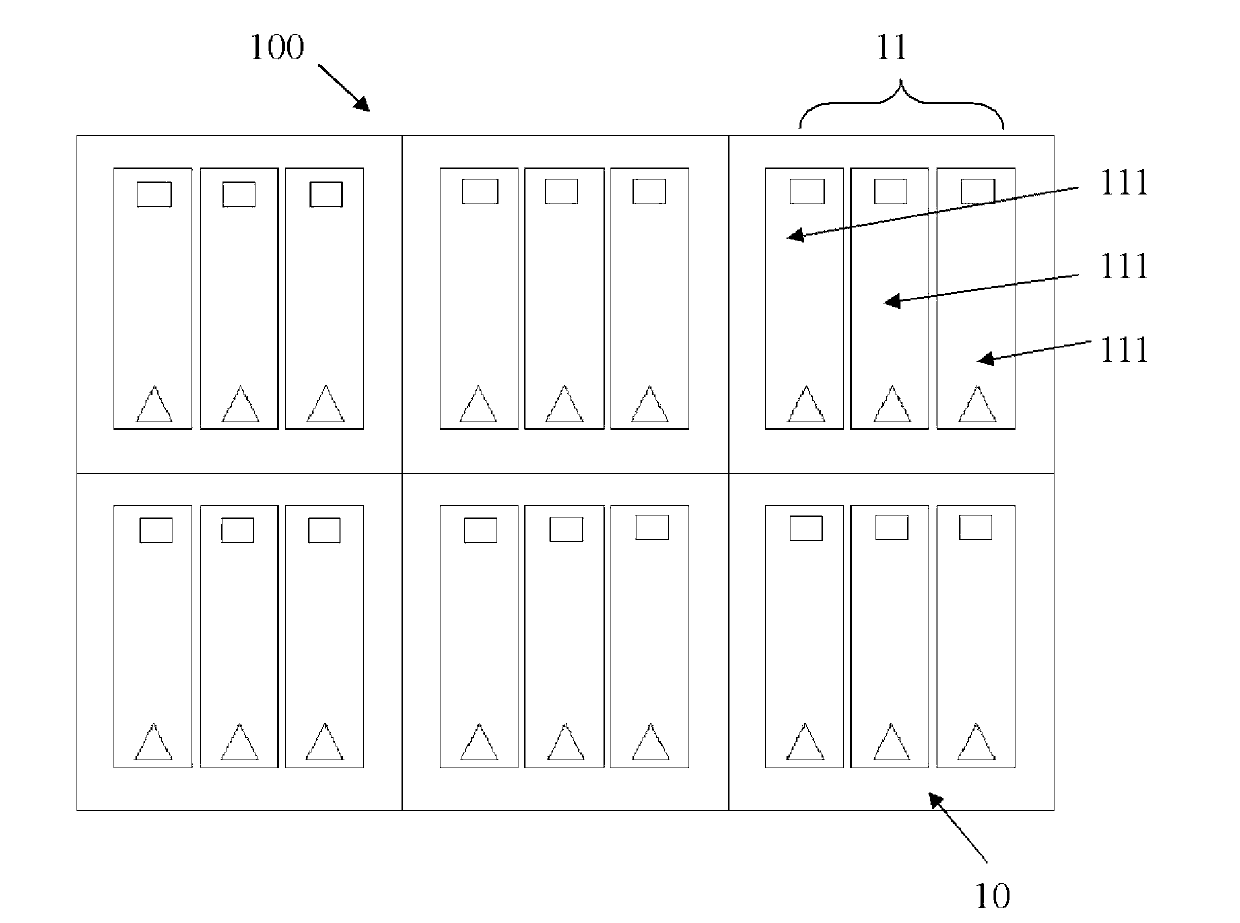

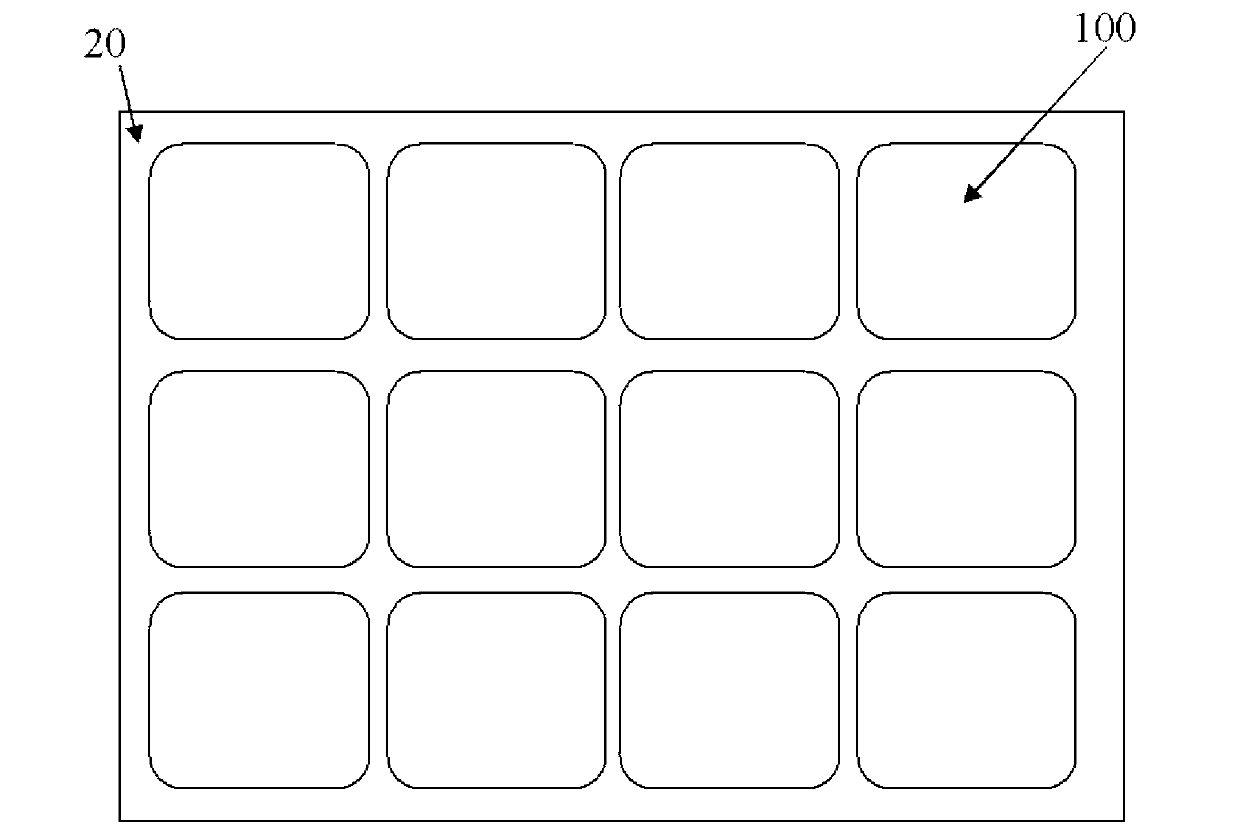

[0020] Step 2: Prepare light-emitting diode unit module 11 on epitaxial wafer 10 (see figure 2 ), forming an LED array 100, the LED unit module 11 includes a plurality of LEDs 111; the number of each group of LEDs 111 in the LED ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com