Low corrosive oxidation potential sterilization water and preparation method thereof

A technology of oxidation potential and sterilizing water, which is applied in the direction of botany equipment and methods, fungicides, chemicals for biological control, etc., to achieve the effect of expanding the application range, convenient use, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Therefore, the present invention provides a kind of preparation method of the oxidation potential sterilization water of low corrosivity, comprises the following steps:

[0060] (1) Provide available chlorine supply units that contain available chlorine or can produce available chlorine;

[0061] (2) Provide pH adjustment unit;

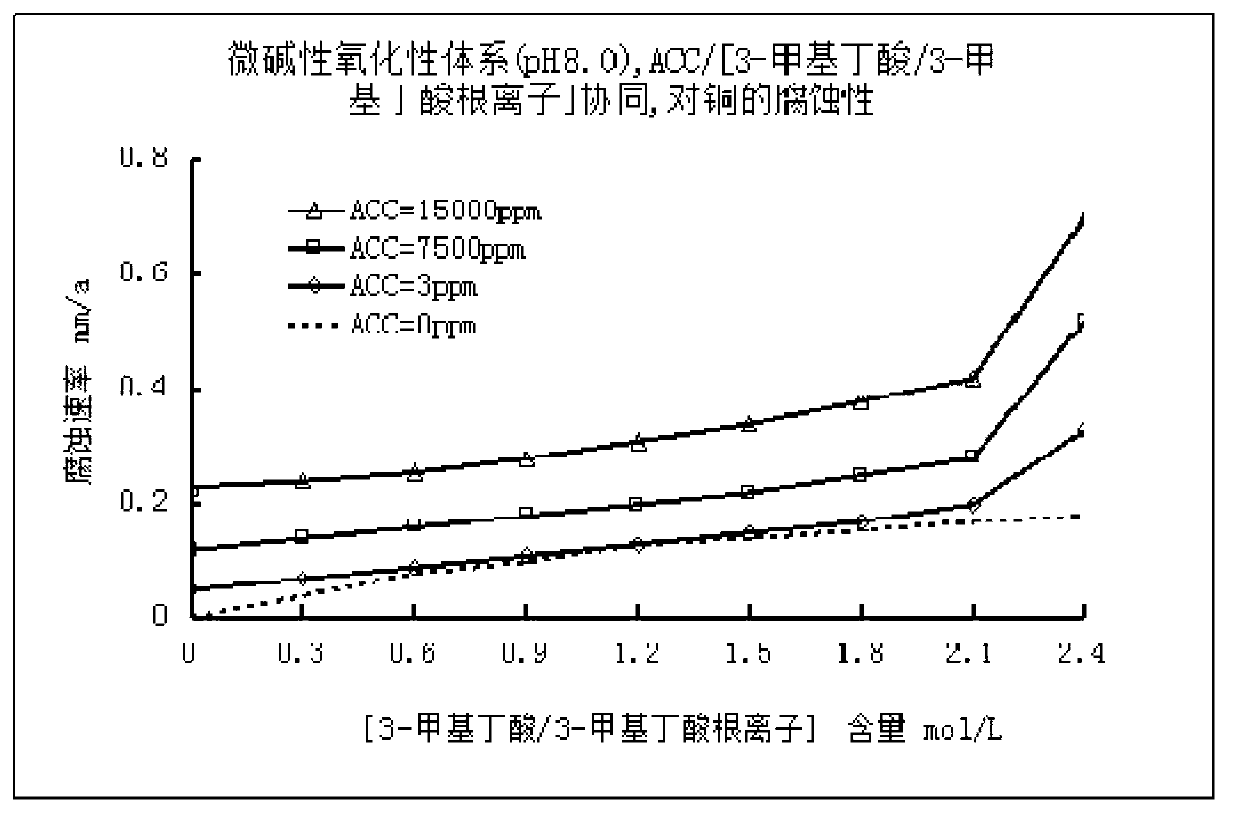

[0062] (3) Mixing the pH adjustment unit with the available chlorine supply unit to obtain a strong oxidizing solution, the pH of the strong oxidizing solution is between 2 and 8, and its oxidation-reduction potential is not lower than 600mV, which The content of available chlorine is not less than 3mg / L, and the sum of the content of 3-methylbutyric acid and 3-methylbutyrate ion is not higher than 1.8mol / L.

[0063] The present invention also provides a low-corrosivity oxidation potential sterilizing water, including a pH value adjustment unit and an available chlorine supply unit that are separately packaged before use; the available chlorin...

Embodiment 1

[0088] Embodiment 1: configure 10L oxidation potential sterilization water

[0089] Prepare different pH adjustment units, units A1-A3:

[0090] Prepare sodium dihydrogen phosphate-sodium monohydrogen phosphate buffer solution (pH6-8) with a total concentration of 0.6M, take 10L, fill it, and make A1 unit, the total concentration refers to the sodium dihydrogen phosphate-sodium hydrogen phosphate sum of concentrations;

[0091] Prepare 3-methylbutyric acid / 3-methylsodium butyrate buffer solution (pH4-6) with a total concentration of 1.5M, take 10L, fill it, and make A2 unit, the total concentration refers to 3-methylbutyrate sum of concentrations of acid / sodium 3-methylbutyrate;

[0092] Prepare 3-methylbutyric acid / 3-methylbutyric acid sodium buffer solution (pH2-4) with a total concentration of 1.8M, take 10L and fill it to obtain unit A3. The total concentration refers to 3-methylbutyrate The sum of acid / sodium 3-methylbutyrate concentrations.

[0093] Preparation of di...

Embodiment 2

[0101] Embodiment 2: configure 10L oxidation potential sterilization water

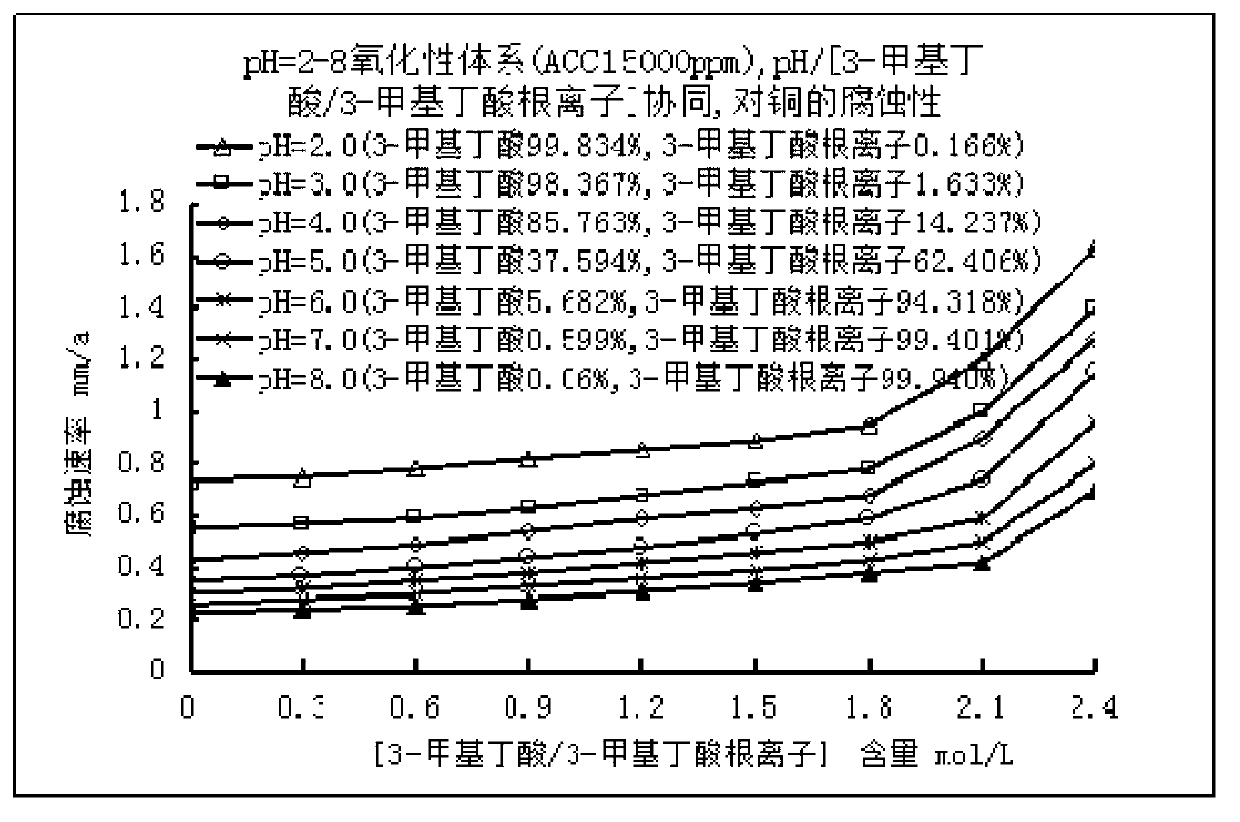

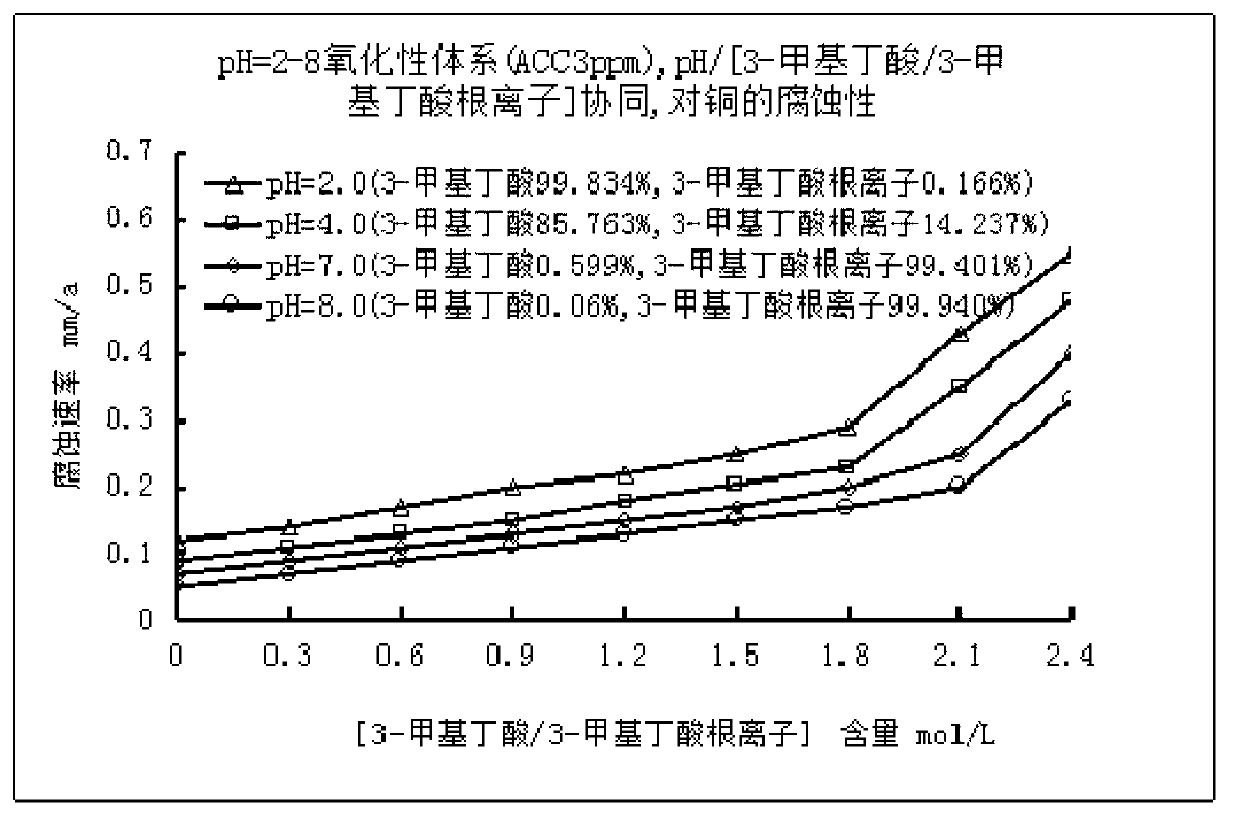

[0102] Preparation of different pH adjustment units, A1-A7 units (solution, [HA / A - ]≥0mol / L):

[0103] Prepare 3-methylbutyric acid solution (1.8M), adjust the hydrochloric acid to pH=2.0, measure 10L, fill it, and make A1 unit (pH2.0), containing [HA / A - ]≈1.8mol / L;

[0104] Prepare 3-methylbutyric acid solution (1.5M), adjust it to pH=3.0 with sodium hydroxide, measure 10L, fill it, and make A2 unit (pH3.0), containing [HA / A - ]≈1.5mol / L;

[0105] Prepare 3-methylbutyric acid solution (1M), adjust it to pH=4.0 with sodium hydroxide, measure 10L, fill it, and prepare A3 unit (pH4.0), containing [HA / A - ]≈1mol / L;

[0106] Prepare 3-methylbutyric acid solution (0.5M), adjust it to pH=5.0 with sodium hydroxide, measure 10L, fill it, and make A4 unit (pH5.0), containing [HA / A - ]≈0.5mol / L;

[0107] Prepare 3-methylbutyrate sodium solution (0.1M), adjust the hydrochloric acid to pH=6.0, measure 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com