A kind of preparation method of tobacco sheet composite fiberboard

A technology of composite fiber and tobacco sheet, applied in the field of tobacco, can solve the problems of insufficient physical and chemical properties, performance and quality, and achieve the effects of enriching the aroma of cigarettes, improving economic benefits, and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Take the chopped and pretreated tobacco rod as raw material, weigh 1000g, add 8000g of 0.5mol / L sodium hydroxide aqueous solution, stir and extract at 90°C for 5h, filter and separate, wash with water, beat with a beater, The deduction degree is controlled at 24-30°SR.

[0053] Take the extracted licorice residue as raw material, weigh 1000g, add 6000g of 0.3mol / L sodium hydroxide aqueous solution, stir and extract at 90°C for 4 hours, filter and separate, wash with water, beat with a beater, and decompose Controlled at 24-30°SR.

[0054] Take 40g of processed tobacco stem pulp, 10g of licorice pulp, add 50g of hemp pulp to form a composite plant fiber formula, and use a cardboard forming machine to produce a composite plant fiber board.

[0055] Adding 10% of the produced composite plant fiberboard into the produced flakes was compared with the flakes produced by adding 10% pure hemp pulp.

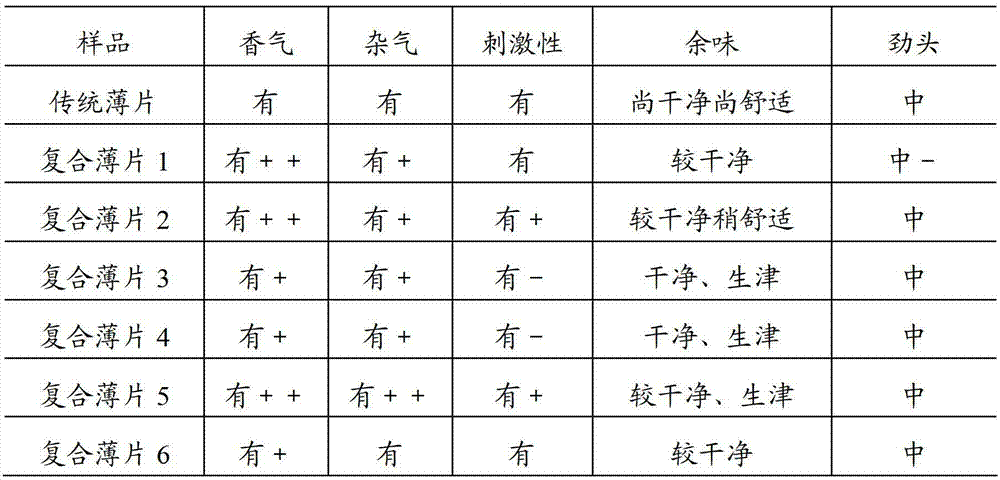

[0056] According to smoking evaluation, the tobacco flakes produced with com...

Embodiment 2

[0058] Take the chopped and pretreated tobacco rod as raw material, weigh 1000g, add 1.0mol / L potassium hydroxide aqueous solution 8000g, stir and extract at 80°C for 5h, filter and separate, wash with water, beat with a beater, The deduction degree is controlled at 24-30°SR.

[0059] Take the extracted licorice residue as raw material, weigh 500g, add 0.5mol / L potassium hydroxide aqueous solution 3000g, stir and extract at 90°C for 4 hours, filter and separate, wash with water, beat with a beater, and decompose Controlled at 24-30°SR.

[0060] Take 45g of processed tobacco stem pulp, 5g of licorice pulp, and 50g of hemp pulp to form a composite plant fiber formula, and use a cardboard forming machine to produce the required composite plant fiber board.

[0061] Adding 10% of the produced composite plant fiberboard into the produced flakes was compared with the flakes produced by adding 10% pure hemp pulp.

[0062] After smoking, the tobacco flakes produced by composite plan...

Embodiment 3

[0064] Take the chopped and pretreated tobacco rod as raw material, weigh 2000g, add 1.0mol / L sodium hydroxide aqueous solution 16000g, stir and extract at 100°C for 4h, filter and separate, wash with water, beat with a beater, The deduction degree is controlled at 24-30°SR.

[0065] Take the extracted licorice residue as raw material, weigh 1000g, add 5000g of 0.5mol / L sodium hydroxide aqueous solution, stir and extract for 3 hours at 100°C, filter and separate, wash with water, beat with a beater, and decompose Controlled at 24-30°SR.

[0066] Take 35g of processed tobacco stem pulp, 15g of licorice pulp, and 50g of hemp pulp to form a composite plant fiber formula, and use a cardboard forming machine to produce the required composite plant fiber board.

[0067] Adding 10% of the produced composite plant fiberboard into the produced flakes was compared with the flakes produced by adding 10% pure hemp pulp.

[0068] After smoking, the smoke of the tobacco sheet produced by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com