Organic fluorine modified solid water-based acrylic resin and preparation method thereof

A water-based acrylic and fluorine-modified technology, which is applied in application, coating, ink, etc., can solve the problems of harsh reaction conditions in continuous polymerization process, failure to reach products in large-scale production, and restrictions on wide application, and achieve good production stability, Good grinding performance and good leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

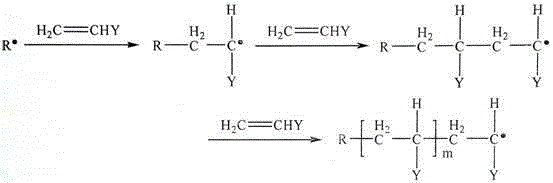

Method used

Image

Examples

preparation example Construction

[0050] The invention also discloses a preparation method of the above-mentioned organic fluorine modified solid waterborne acrylic resin, which includes the following steps:

[0051] S1. Mixing 40-50 parts by weight of propylene glycol methyl ether and 40-50 parts of ethylene glycol monobutyl ether as a solvent is added to the reaction kettle, and a certain amount of protective gas is filled to protect the reaction;

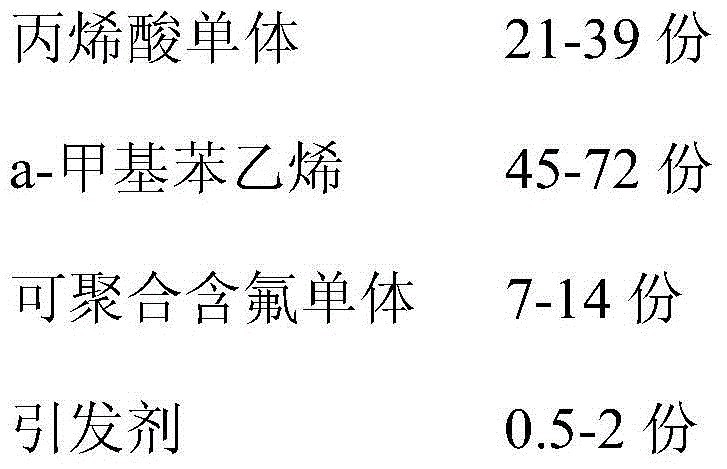

[0052] S2. The temperature of the reaction kettle is raised to 90-120 degrees after 15 minutes, and mixture I is started to be added dropwise to the reaction kettle. The mixture I is composed of 21-39 parts by weight of acrylic monomer and 45 parts by weight of a-methylstyrene. -72 parts and 7-14 parts of polymerizable fluorine-containing monomer are mixed, and the mixture I is added dropwise within 10-30 minutes, and the reaction degree during the reaction is checked. Among them, the acrylic monomer is acrylic acid, methacrylic acid or a mixture thereof, and the poly...

Embodiment 1

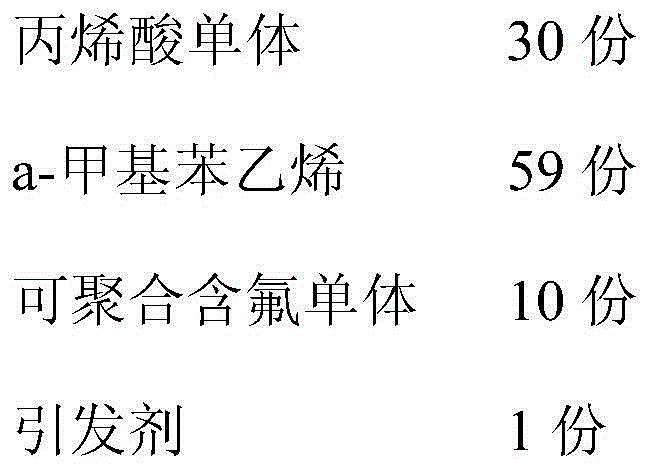

[0078] Example 1: The organic fluorine-modified solid waterborne acrylic resin of this example consists of the following reaction materials in parts by weight: 30 kg of acrylic acid, 59 kg of a-methyl styrene, 10 kg of dodecafluoroheptyl methacrylate, 1 kg of benzoyl oxide was added to a mixed solvent consisting of 45 kg of propylene glycol methyl ether and 45 kg of ethylene glycol monobutyl ether, mixed into a solution and polymerized to obtain a solid waterborne acrylic resin.

[0079] The preparation method of the above organic fluorine modified solid waterborne acrylic resin includes the following steps:

[0080] S1. Add a mixed solvent consisting of 45kg of propylene glycol methyl ether and 45kg of ethylene glycol monobutyl ether into the reaction kettle, and fill a certain amount of protective gas to protect the reaction;

[0081] S2. The reaction kettle was heated to 100°C after 15 minutes, and the monomer mixture of 30 kg acrylic acid, 59 kg a-methyl styrene and 10 kg dodecaf...

Embodiment 2

[0086] Example 2: The organic fluorine-modified solid waterborne acrylic resin of this example consists of the following reaction materials in parts by weight: 21 kg of methacrylic acid, 45 kg of a-methyl styrene, and 7 kg of dodecafluoroheptyl methacrylate , 0.5 kg of benzoyl peroxide is added to a mixed solvent consisting of 40 kg of propylene glycol methyl ether and 40 kg of ethylene glycol monobutyl ether, mixed to form a solution and polymerized to obtain a solid aqueous acrylic resin.

[0087] The preparation method of the above organic fluorine modified solid waterborne acrylic resin includes the following steps:

[0088] S1. Add a mixed solvent consisting of 40 kg of propylene glycol methyl ether and 40 kg of ethylene glycol monobutyl ether into the reaction kettle, and fill a certain amount of protective gas to protect the reaction;

[0089] S2. After 15 minutes, the reactor was heated to 90°C, and the monomer mixture of 21kg methacrylic acid, 45kg a-methylstyrene and 7kg do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com