Preparation method of demulsifier polyether intermediate compound

A technology of intermediates and demulsifiers, which is applied in the field of preparation of demulsifier polyether intermediates, can solve the problems of energy waste, difficult to handle, and high processing costs, and achieve reduced environmental pollution and good economic and social benefits , The effect of reducing the cost of demulsification and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

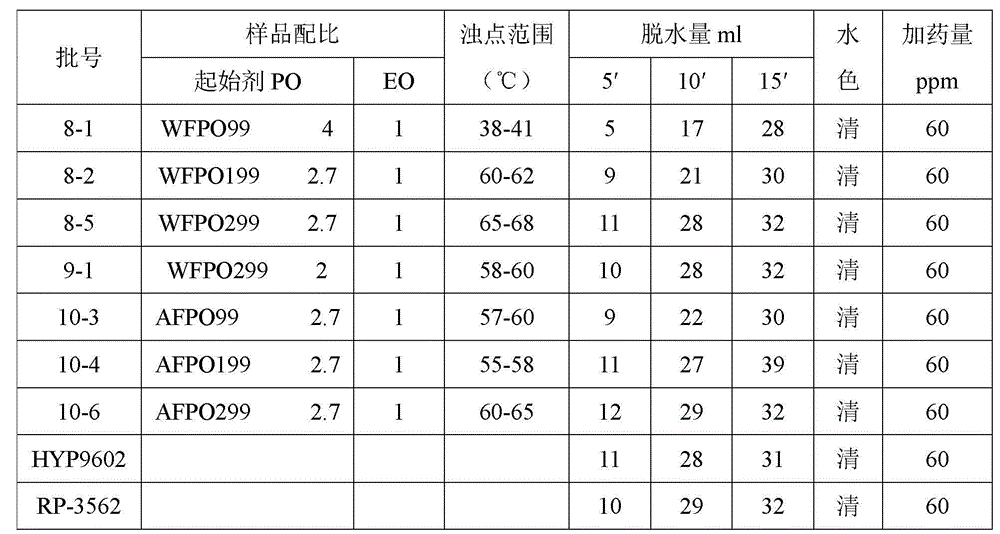

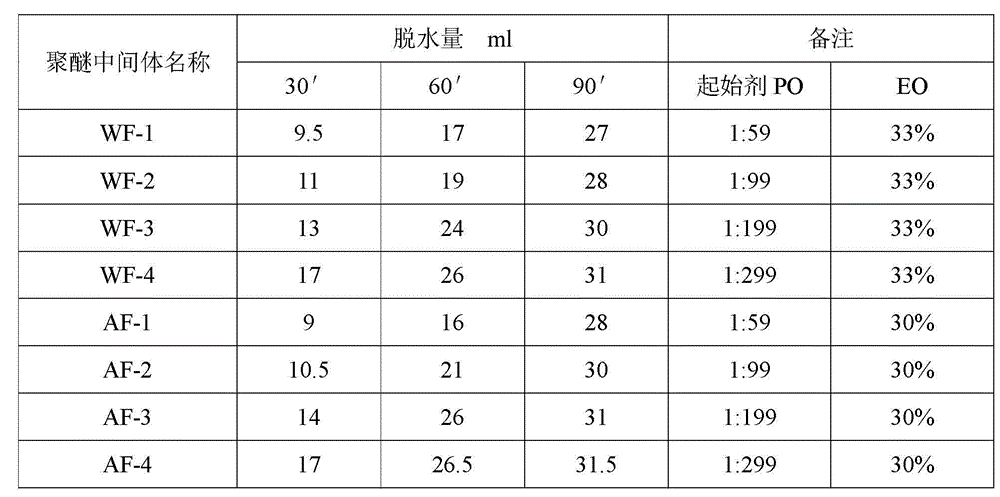

[0015] Preparation of polyether intermediates

[0016] 1. Main raw materials

[0017] EO, first-class industrial product; PO, first-class industrial product; KOH, first-class industrial product; linking agent, first-class industrial product; regulator, self-made; solvent, qualified industrial product; organic phenol, first-class industrial product; organic Amines, first-class industrial products; formaldehyde, first-class industrial products.

[0018] 2. The main equipment of the small test

[0019] G-type high-pressure stainless steel reaction kettle 2 L, vacuum pump 1406, glass constant temperature water bath.

[0020] 3. Synthesis principle

[0021] Under the action of a catalyst, the initiator polymerizes with POEO to form a polyether, which can be expressed by the following formula:

[0022] WF-(OH)x+nPO+mEO→WF[(PO)n(EO)m]x,

[0023] AF-(NH 2 )y+nPO+mEO→AF[(PO)n(EO)m]y,

[0024] WF-(OH)x WF resin with polyhydroxyl,

[0025] AF-(NH 2 ) y AF resins with polyamine g...

Embodiment 1

[0034] Preparation of initiator thermoplastic resin: the C 4-9 Organic phenol and diethylenetriamine are mixed in a mass ratio of 1:2, heated and controlled at 30-40°C, stirred for 30 minutes, and the mass ratio C 4-9 Organic phenol: formaldehyde is added dropwise with formaldehyde at a ratio of 1:2. After the dropwise addition is completed, the temperature is raised to 150-170°C, and the temperature is controlled for 3 hours to react to obtain a new type of thermoplastic resin.

[0035] Preparation of polyether intermediate: Add sodium hydroxide to the thermoplastic resin, stir while heating, heat to 90°C, turn on the vacuum pump for 30 minutes, control the temperature at 115-135°C, add propylene oxide, epoxy After feeding the ethane, react at a temperature of 115-135°C and a pressure of 0.1-0.3Mpa for 30 minutes, lower the temperature to 90°C, and turn on the vacuum pump for 30 minutes to obtain a polyether intermediate.

[0036] The amount of each component added is 1:50:2...

Embodiment 2

[0038] Preparation of initiator thermoplastic resin: the C 4-9 Organic phenol and triethylenetetramine are mixed according to the mass ratio of 1:3, heated and controlled at 30-40°C, stirred for 30 minutes, according to the mass ratio C 4-9 Formaldehyde is added dropwise at a ratio of organic phenol: formaldehyde of 1:6. After the dropwise addition, the temperature is raised to 150-170°C, and the temperature is controlled for 3 hours to obtain a new thermoplastic resin.

[0039] Preparation of polyether intermediate: Add potassium hydroxide to the thermoplastic resin, stir while heating, heat to 90°C, turn on the vacuum pump for 30 minutes, control the temperature at 115-135°C, and continuously add propylene oxide, epoxy After feeding the ethane, react at a temperature of 115-135°C and a pressure of 0.1-0.3Mpa for 30 minutes, lower the temperature to 90°C, and turn on the vacuum pump for 30 minutes to obtain a polyether intermediate.

[0040] Wherein the addition amount of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com