Orthotropic steel plate-composite material hollow slab combined bridge floor structure

A composite material, orthotropic technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as hidden safety hazards, damage to asphalt mixture pavement, fatigue cracking of steel bridge deck structures, etc., to achieve stable high temperature stability. and low temperature crack resistance, high stiffness, anti-cracking effect of pavement layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

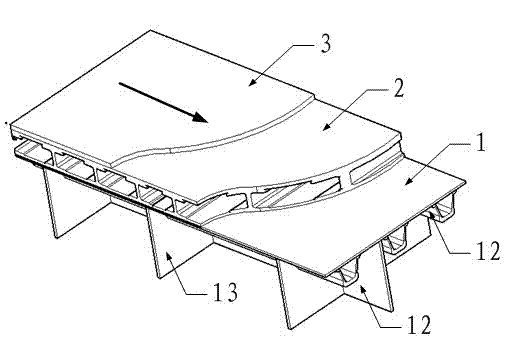

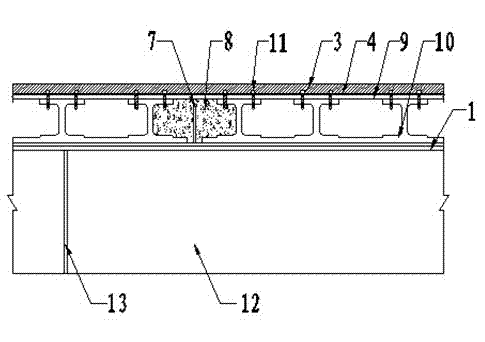

[0025] The orthotropic steel plate-composite material hollow plate combined deck structure of the present invention comprises an orthotropic steel plate 1, on which the orthotropic steel plate 1 is provided with a shear bond 7, and a layer of 110 mm is arranged on the upper surface of the orthotropic steel plate 1 A thick composite material hollow plate 2, the composite material hollow plate 2 is composed of a 10mm thick top plate 9 and a 100mm thick open I-shaped bottom plate 10. The top and bottom panels are pultruded from fiberglass and vinyl. The composite material hollow plate 2 is connected with the orthotropic steel plate 1 through structural adhesive and shear bond system 5 as a whole, and a layer of looped fabric is laid on the composite material hollow plate 2 to form a rough layer 4, and finally a layer of 2cm thick asphalt is poured Mixed wearing layer 3.

Embodiment 2

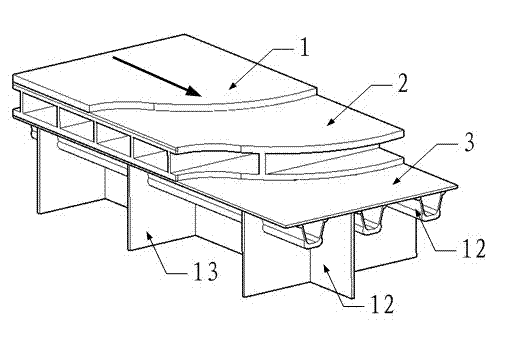

[0027] The orthotropic steel plate-composite material hollow plate combined bridge deck structure of the present invention comprises an orthotropic steel plate 1, a shear bond 7 is arranged on the orthotropic steel plate 1, and a layer of 100 mm is arranged on the upper surface of the orthotropic steel plate 1 Thick composite material hollow board 2, the composite material hollow board 2 is composed of a 10mm thick top board 9 and a 90mm thick straight-belly multi-chamber bottom board 10. The top and bottom panels are pultruded from fiberglass and vinyl. Composite material hollow slab 2 is connected with orthotropic steel plate 1 through structural glue and shear bond system 5 as a whole, a layer of crushed stone is laid on top of composite material hollow slab 2 to form rough layer 4, and finally a layer of 3cm thick asphalt mixture is poured Wear layer 3.

Embodiment 3

[0029] The orthotropic steel plate-composite material hollow plate combined bridge deck structure of the present invention comprises an orthotropic steel plate 1, a shear bond 7 is arranged on the orthotropic steel plate 1, and a layer of 100 mm is arranged on the upper surface of the orthotropic steel plate 1 Thick composite material hollow board 2, the composite material hollow board 2 is composed of a 10mm thick top board 9 and a 90mm thick inclined belly type multi-chamber bottom board 10. The top and bottom panels are pultruded from fiberglass and vinyl. Composite material hollow slab 2 is connected with orthotropic steel plate 1 through structural glue and shear bond system 5 as a whole, a layer of gravel is laid on the top of composite material hollow slab 2 to form rough layer 4, and finally a layer of 2cm thick asphalt mixture is poured Wear layer 3.

[0030] The preparation method of the factory-prefabricated orthotropic steel plate-composite material hollow plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com