Construction method of vacuum insulation plate wall body

A technology of vacuum thermal insulation board and construction method, which is applied in the directions of thermal insulation, wall and insulation improvement, etc., can solve the problems of poor wall thermal insulation coefficient and uniformity, increase of material cost and labor cost, and high construction difficulty and complexity. The overall thermal insulation performance is improved, the overall thermal insulation performance is improved, and the surface flatness is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

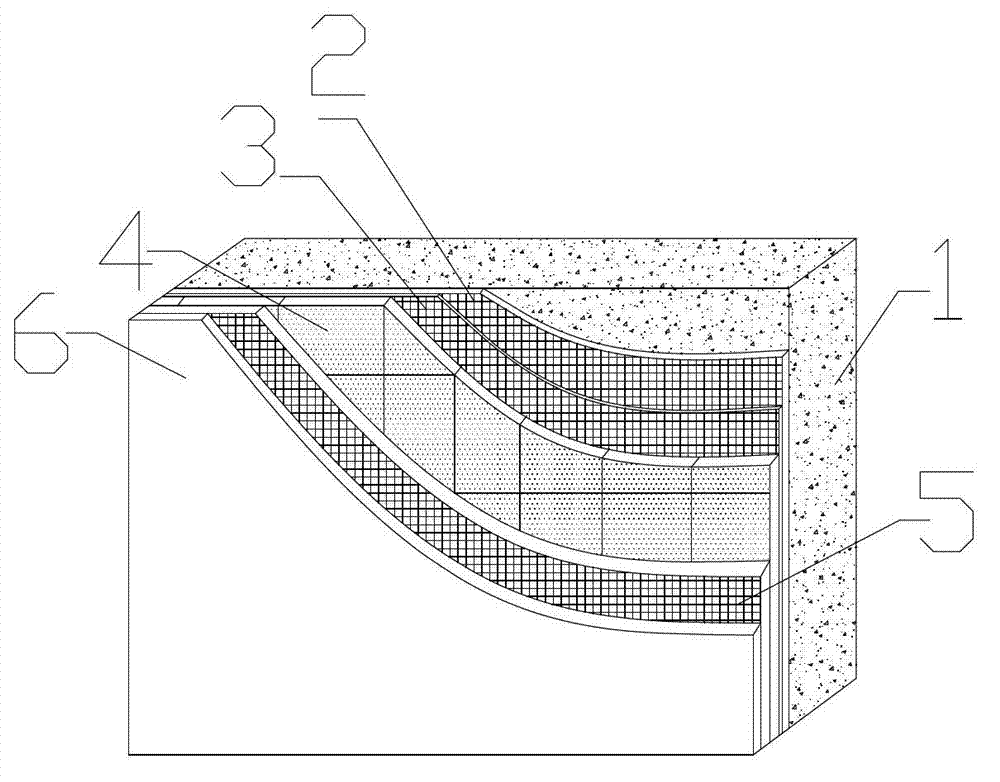

[0031] figure 1 To decorate the exterior wall with a light load, spray a layer of polyurethane (2) 2-7mm evenly on the base surface (1) of the wall during construction to level and pave the wall; then, according to the area to be laid, generally 4-20㎡, adjust and prolong the curing time of the second spraying of polyurethane, generally between 2-4 minutes, which can be adjusted according to the actual needs of the laying area. After the adjustment is completed, evenly spray the second layer of polyurethane (3) 2-7mm on the bonding surface polyurethane (2), and quickly lay the aluminum foil vacuum board (4) neatly before the polyurethane layer (3) is cured On the base surface (3), after spraying the polyurethane to cure, continue to spray the surface polyurethane layer (5) 5-15mm, and fill and cover the blank spots on the surface of the aluminum foil vacuum board and joints. The polyurethane sprayed on the surface polyurethane layer gently wraps the vacuum panel in it through ...

Embodiment 2

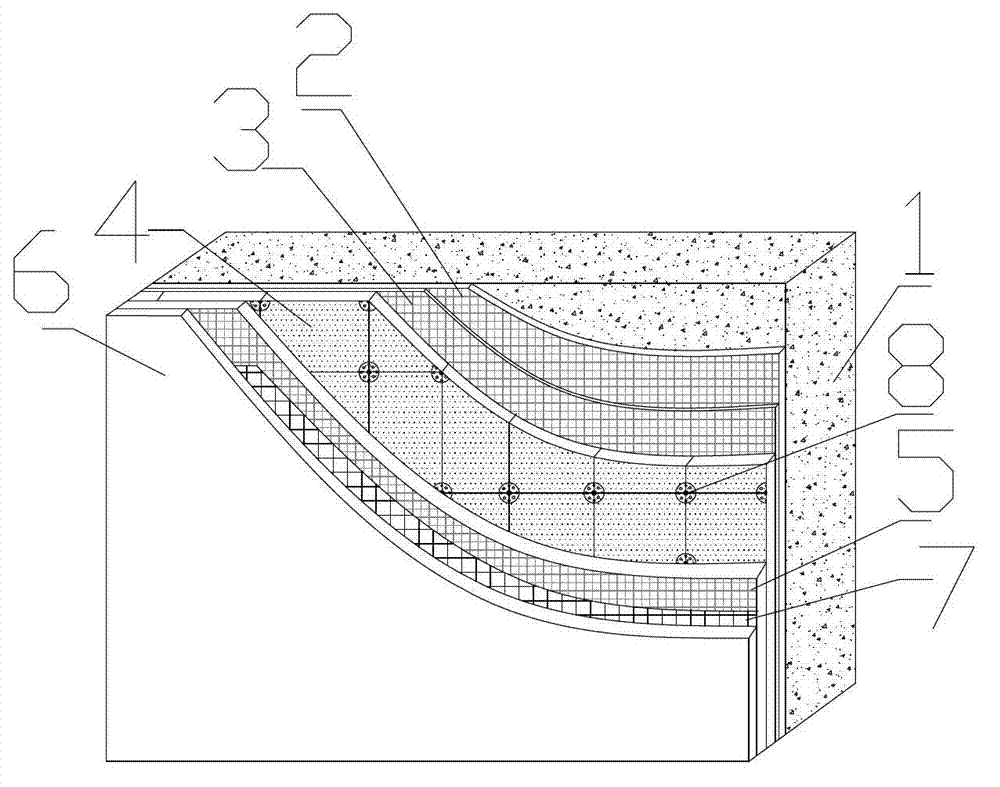

[0033] The vacuum insulation board fixing part is mainly composed of three parts: the wall fixing part, the beam-shaped vacuum board supporting part and the vacuum board fixing part. Each fixing part can fix four vacuum panel corners at a time, and the fixing parts can be made of suitable common materials on the market such as PVC; Figure 4 Middle: (11) Fixed back plate, (12) Beam support, (13) Fixed plate, (14) Fixed buckle, (15) Reserved nail holes for fixing to the wall, (16) Reserved holes for fixed plate .

[0034] During construction, spray a layer of polyurethane (2) 2-7mm evenly on the base surface of the wall (1) to level and lay the wall surface; then, fix the vacuum board fixing part (11) on the base surface of the wall with nails (1) Above, the spacing and size of the empty board fixing parts (11) are determined according to the size of the vacuum board, and the basic size is about 400×600, 600×800mm. After all the vacuum panels are fixed, continue to spray the ...

Embodiment 3

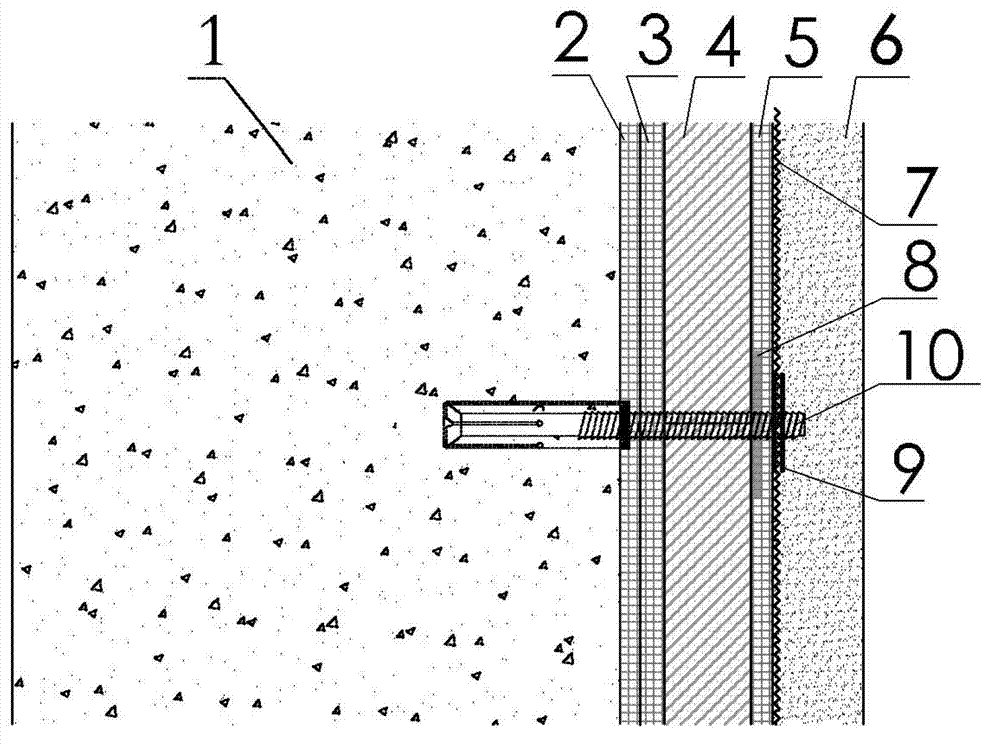

[0036] image 3 It is suitable for exterior wall decoration with heavy loads. During construction, holes are drilled on the base surface of the wall (1) to fix the anchor bolts (10). The distance between the anchor bolts is determined according to the size of the vacuum plate, and the length of the anchor bolt rod is 8 times higher than the laid vacuum plate. -15mm, the anchor cap is slightly higher than the base surface of the wall, and the threaded anchor rod on the exposed part of the anchor is used to fix the metal mesh. During construction, first fix the anchor bolts, tighten the nuts to expand the expansion bolts, and firmly squeeze them on the base surface of the wall (1). Then, spray a layer of polyurethane (2) evenly on the base surface of the wall. 2 -7mm, perform leveling and padding, seal the anchor bolt holes with plastic tape before spraying, and prevent the anchor bolt holes from being covered during polyurethane spraying. Then put a plastic tube on the bolt ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com