Manufacturing method for flooded maintenance-free power-type lead-acid storage battery

A lead-acid battery and a manufacturing method technology, applied in lead-acid battery, lead-acid battery construction, battery electrodes and other directions, can solve problems such as electrolyte easy to corrode electronic components of equipment, easy occurrence of liquid shortage, acid mist precipitation, etc. Reduce the possibility of electrolyte overflow and acid mist precipitation, improve safety and reliability, and reduce the effect of gas evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

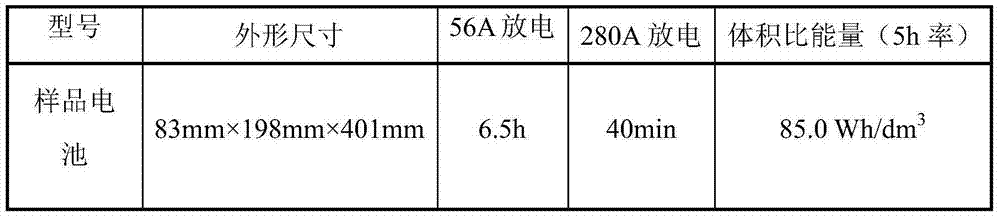

[0023] Manufactured 2V280Ah rich liquid maintenance-free power lead-acid battery.

[0024] a. The shell is made of PP material;

[0025] b. The partition adopts PE partition with glass fiber inside;

[0026] c. For the production of positive grids, after melting 100Kg of positive grid lead-calcium alloy materials in a lead melting furnace, the temperature is raised to 500°C, stirred for 20 minutes, and cast in a positive grid mold to form a positive grid; The mass percentage of each component of the positive grid lead-calcium alloy material is: 0.01% Ca, 0.5% Sn, 0.01% Al, and the balance is Pb;

[0027] d. For the production of negative grids, after melting 100Kg of negative grid lead-calcium alloy materials in a lead melting furnace, the temperature is raised to 500°C, stirred for 20 minutes, and cast in a negative grid mold to form a negative grid; The mass percentage of each component of the negative grid lead-calcium alloy material is: 0.01% Ca, 0.1% Sn, 0.01% Al, and the balanc...

Embodiment 2

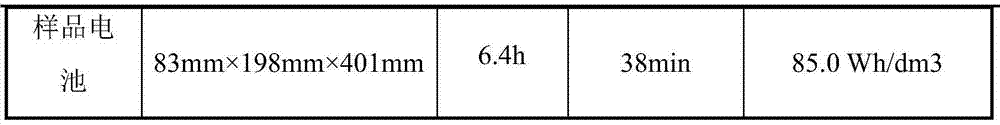

[0035] Manufactured 2V280Ah rich liquid maintenance-free power lead-acid battery.

[0036] a. The shell is made of PP material;

[0037] b. The partition adopts PE partition with glass fiber inside;

[0038] c. For the production of positive grids, after melting 100Kg of positive grid lead-calcium alloy materials in a lead melting furnace, the temperature is raised to 500°C, stirred for 20 minutes, and cast in a positive grid mold to form a positive grid; The mass percentage of each component of the positive grid lead-calcium alloy material is: 1% Ca, 1.25% Sn, 0.25% Al, and the balance is Pb;

[0039] d. For the production of negative grids, after melting 100Kg of negative grid lead-calcium alloy materials in a lead melting furnace, the temperature is raised to 500°C, stirred for 20 minutes, and cast in a negative grid mold to form a negative grid; The mass percentage of each component of the negative grid lead-calcium alloy material is: 1% Ca, 0.5% Sn, 0.25% Al, and the balance is ...

Embodiment 3

[0048] Manufactured 2V280Ah rich liquid maintenance-free power lead-acid battery.

[0049] a. The shell is made of PP material;

[0050] b. The partition adopts PE partition with glass fiber inside;

[0051] c. For the production of positive grids, after melting 100Kg of positive grid lead-calcium alloy materials in a lead melting furnace, the temperature is raised to 500°C, stirred for 20 minutes, and cast in a positive grid mold to form a positive grid; The mass percentage of each component of the positive grid lead-calcium alloy material is: 2% Ca, 2% Sn, 0.5% Al, and the balance is Pb;

[0052] d. For the production of negative grids, after melting 100Kg of negative grid lead-calcium alloy materials in a lead melting furnace, the temperature is raised to 500°C, stirred for 20 minutes, and cast in a negative grid mold to form a negative grid; The mass percentage of each component of the negative grid lead-calcium alloy material is: 2% Ca, 1% Sn, 0.5% Al, and the balance is Pb;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com