Device for waste gas treatment through normal-temperature regeneration of active carbon

An exhaust gas treatment device and activated carbon technology, applied in the field of industrial air purification, can solve the problems of not meeting the general trend of energy saving and enterprise cost requirements, changing the chemical structure of the fiber surface, and reducing the value of repeated use for many times, so as to achieve a complete exhaust gas purification effect. , the effect of improving regeneration efficiency and improving exhaust gas treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

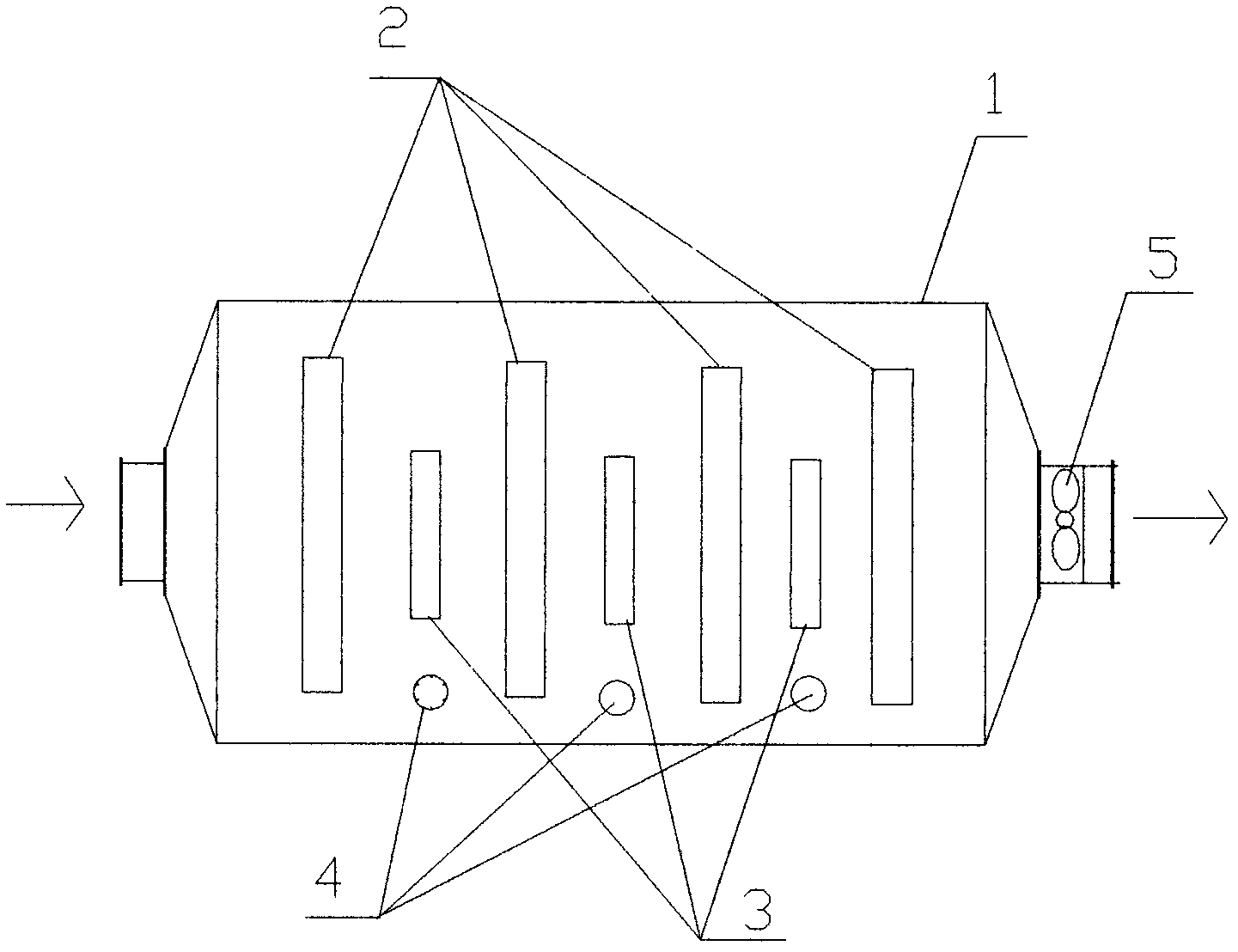

[0015] like figure 1 As shown, the activated carbon regeneration waste gas treatment device at normal temperature includes a shell 1, the two ends of the shell 1 are the gas inlet and outlet respectively, and a plurality of activated carbon devices 2 are arranged at intervals in the shell 1, and a vacuum is provided between two adjacent activated carbon devices 2. An ultraviolet lamp 3 and an ozone generator 4; a metal coating is provided on the inner wall of the housing 1; a fan 5 is provided at the gas outlet end of the housing 1;

[0016] The vacuum ultraviolet lamp 3 produces ultraviolet light with a wavelength of 185nm. At normal temperature, the vacuum ultraviolet lamp 3 irradiates the activated carbon device 2 to cause photolysis of the adsorbate, and simultaneously produces a large amount of hydroxyl radicals, hydrogen peroxide, and oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com