Ethylbenzene dehydrogenation method in presence of mild oxidant

A technology of ethylbenzene dehydrogenation and catalyst, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of large steam consumption, high dehydrogenation reaction temperature, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

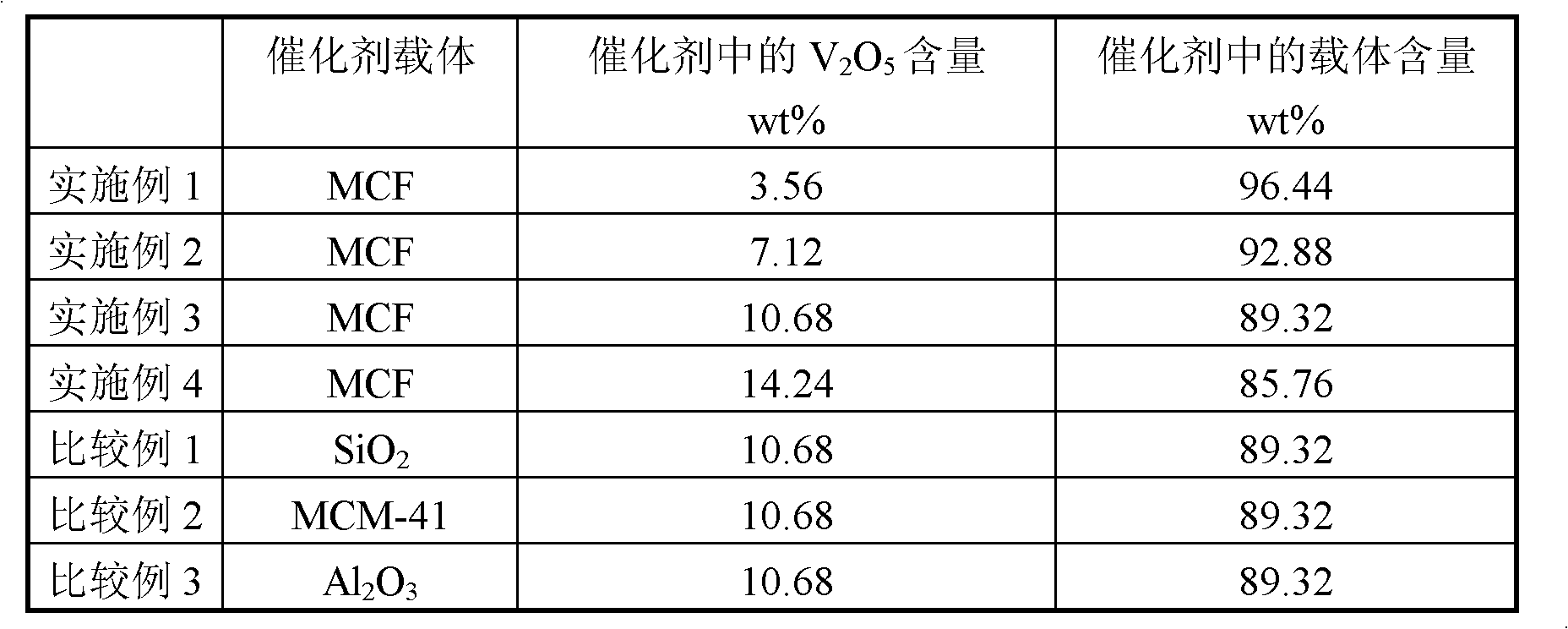

[0019] 80mg V 2 o 5 A loading of 3.56wt% V 2 o 5 / MCF catalyst was loaded into a stainless steel reactor with a diameter of 5mm, the temperature was programmed to 550°C, the heating rate was 20°C / min, and the reaction temperature was 550°C. Before the reaction, the catalyst was activated in a nitrogen atmosphere at 550°C for 2h. Make N 2 with CO 2 The mixed gas will bring ethylbenzene into the reactor through the ethylbenzene saturated steam generator at 15°C, N 2 , CO 2 The molar ratio to ethylbenzene is 120:20:1, and the total gas flow rate is 60ml min -1 . The composition and reaction conditions of the catalyst are shown in Table 1, and the performance of the catalyst under all conditions is shown in Table 2.

Embodiment 2、3、4

[0021] The amount of catalyst remains the same, only the V in the catalyst 2 o 5 The loads were adjusted to 7.12, 10.68 and 14.24wt%, and the rest were the same as in Example 1. The composition and reaction conditions of the catalyst are shown in Table 1, and the performance of the catalyst under all conditions is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com