Silicone fine particles and production method thereof

A technology of organosilicon and microparticles, applied in chemical instruments and methods, medical preparations containing active ingredients, inorganic chemistry, etc., can solve the problem of not being able to provide soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

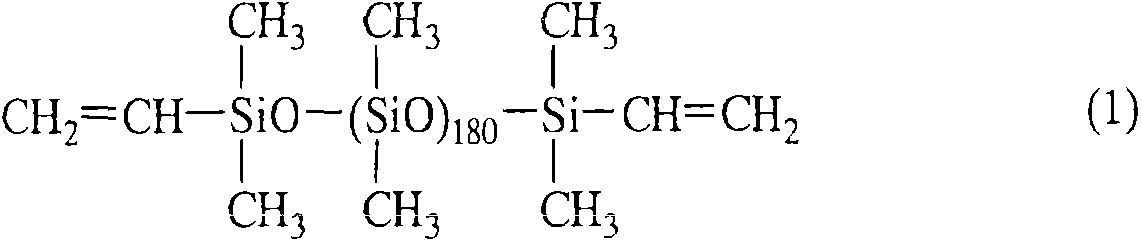

[0071] with 600mm 2 The methyl vinyl polysiloxane represented by the following formula (1) of 500g of / s viscosity and have 30mm 220 g of methylhydrogenpolysiloxane of the following formula (2) with a viscosity per s (the amount is 1.11 hydrosilyl groups (SiH groups) relative to 1 ethylenically unsaturated group, such as a vinyl group) ) into a 1-liter glass beaker, and then the mixture was stirred and dissolved by a homomixer at 2,000 rpm. Next, 3 g of polyoxyethylene lauryl ether (ethylene oxide addition, 9 moles) and 60 g of water were added, and the mixture was stirred at 6,000 rpm by a homomixer to prepare a viscosity-increased oil-in-water emulsion. The mixture was stirred for a further 15 minutes. When 415 g of water were added with stirring at 2,000 rpm, a consistent white emulsion was obtained. This emulsion was transferred to a 1 liter glass flask equipped with a stirring device with an anchored stirring paddle and the temperature adjusted to 15 to 20°C. Under st...

Embodiment 2

[0081] Except that 2.7 g of sodium N-myristoyl sarcosinate (anionic surfactant) was replaced by 0.6 g of sodium N-myristoyl sarcosinate (anionic surfactant) and 2.1 g of sodium lauryl phosphate (anionic surfactant) (in an amount such that a total of 0.1 parts by weight of sodium N-myristoyl sarcosinate and sodium lauryl phosphate is added to 100 parts by weight of water when the base is added as described below), the implementation was repeated The procedure of Example 1 was used to prepare silicone microparticles.

[0082] The obtained silicone fine particles were dispersed in water by using a surfactant, and the volume average particle size measured using "Multisizer 3" (electric resistance method particle size distribution analyzer manufactured by Beckman Coulter) was 6 μm.

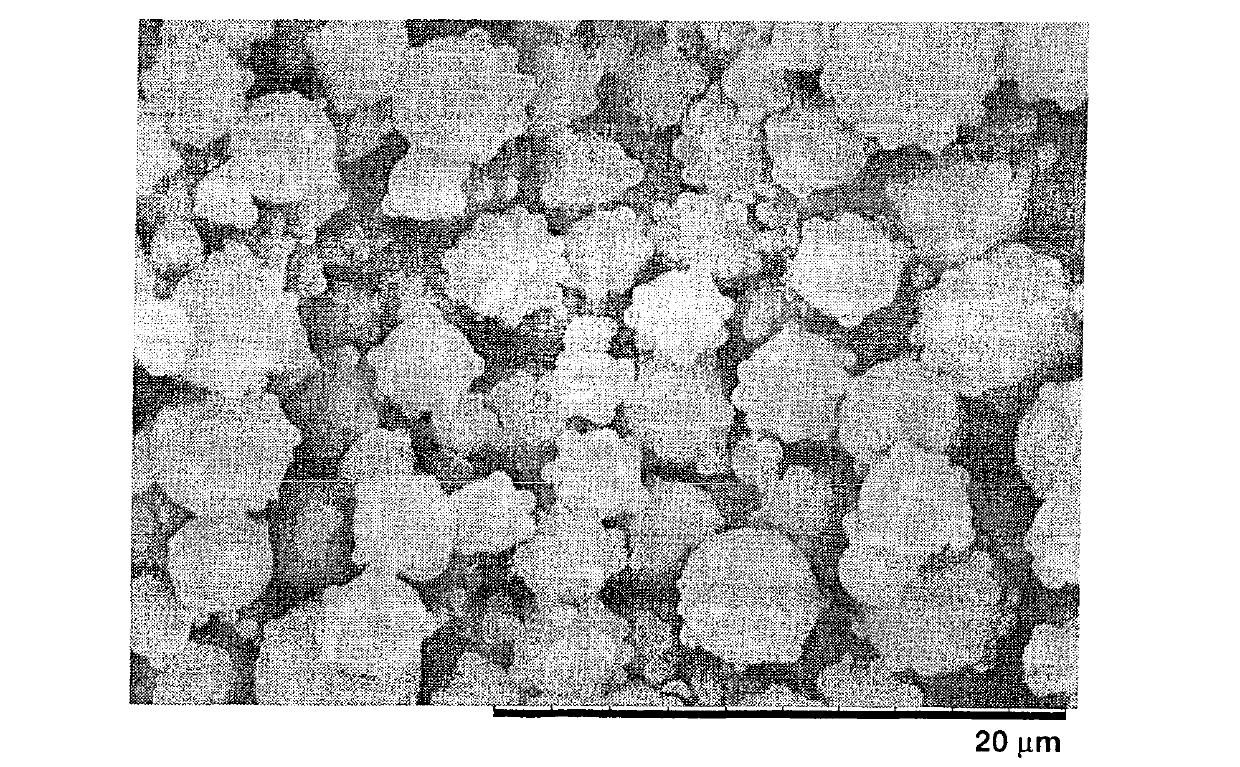

[0083] Observing the obtained silicone microparticles using an electron microscope, the microparticles were found to be in the form of spherical silicone elastomer microparticles having spherical polym...

Embodiment 3

[0085] Except that 2.7 g of sodium N-myristoyl sarcosinate (anionic surfactant) was replaced by 9 g of 30% sodium N-lauroylmethylalanine (anionic surfactant) in an amount such that Except adding 0.1 part by weight of sodium N-lauroylmethylalanine relative to 100 parts by weight of water under the alkaline substance), the steps of Example 1 were repeated to prepare silicone particles.

[0086] The obtained silicone fine particles were dispersed in water by using a surfactant, and the volume average particle size measured using "Multisizer 3" (electric resistance method particle size distribution analyzer manufactured by Beckman Coulter) was 5 μm.

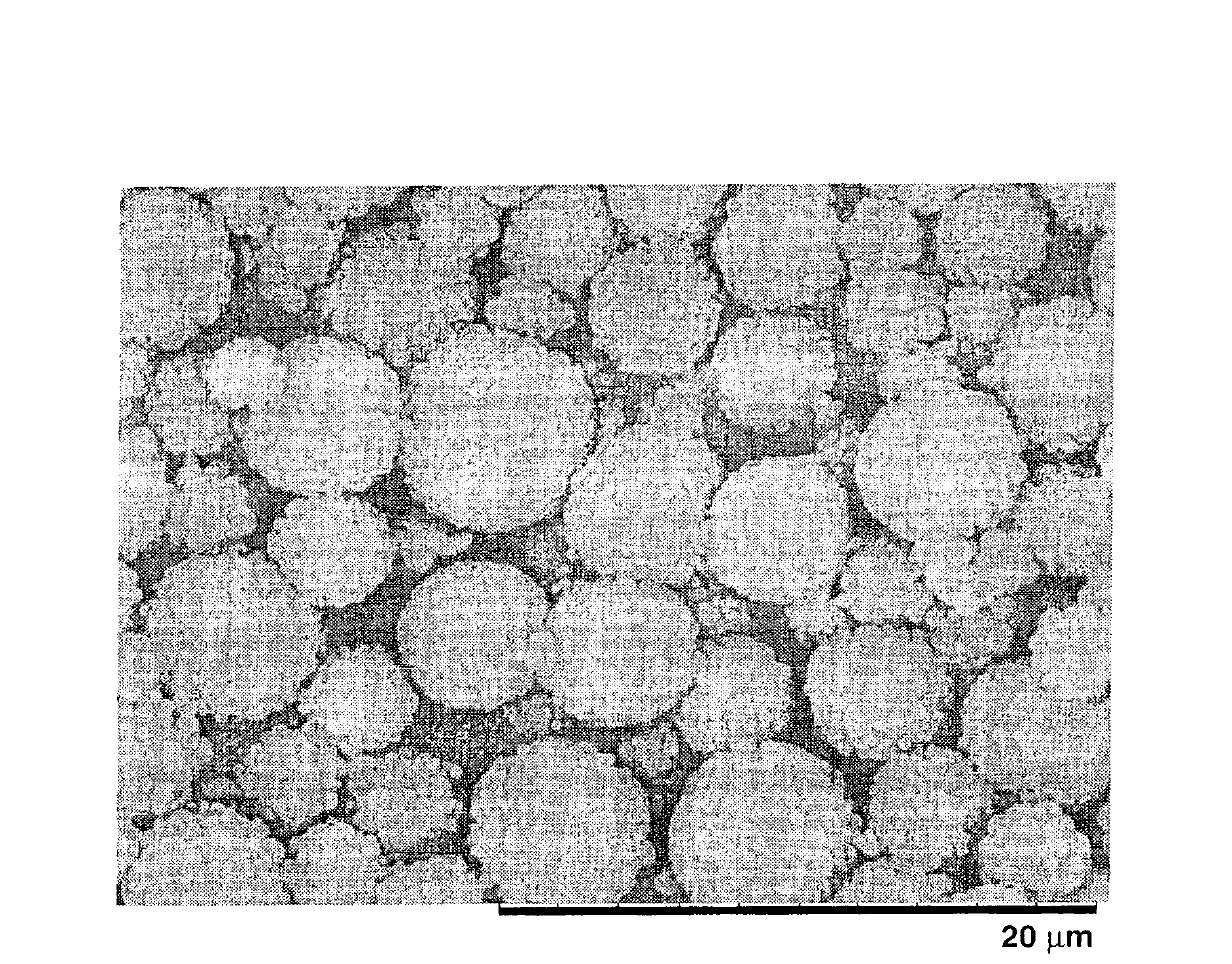

[0087] The obtained silicone microparticles were observed using an electron microscope, and the microparticles were found to be in the form of spherical silicone elastomer microparticles having 700 nm-sized polymethylsilsesquioxane hemispheres sparsely attached to their surfaces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com