Preparation method of binding agent

An adhesive, high-viscosity technology, applied in the direction of adhesive types, starch adhesives, non-polymer adhesive additives, etc., can solve the problems of waste, poor fluidity, poor viscosity, etc., to increase the cohesiveness , good liquidity, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

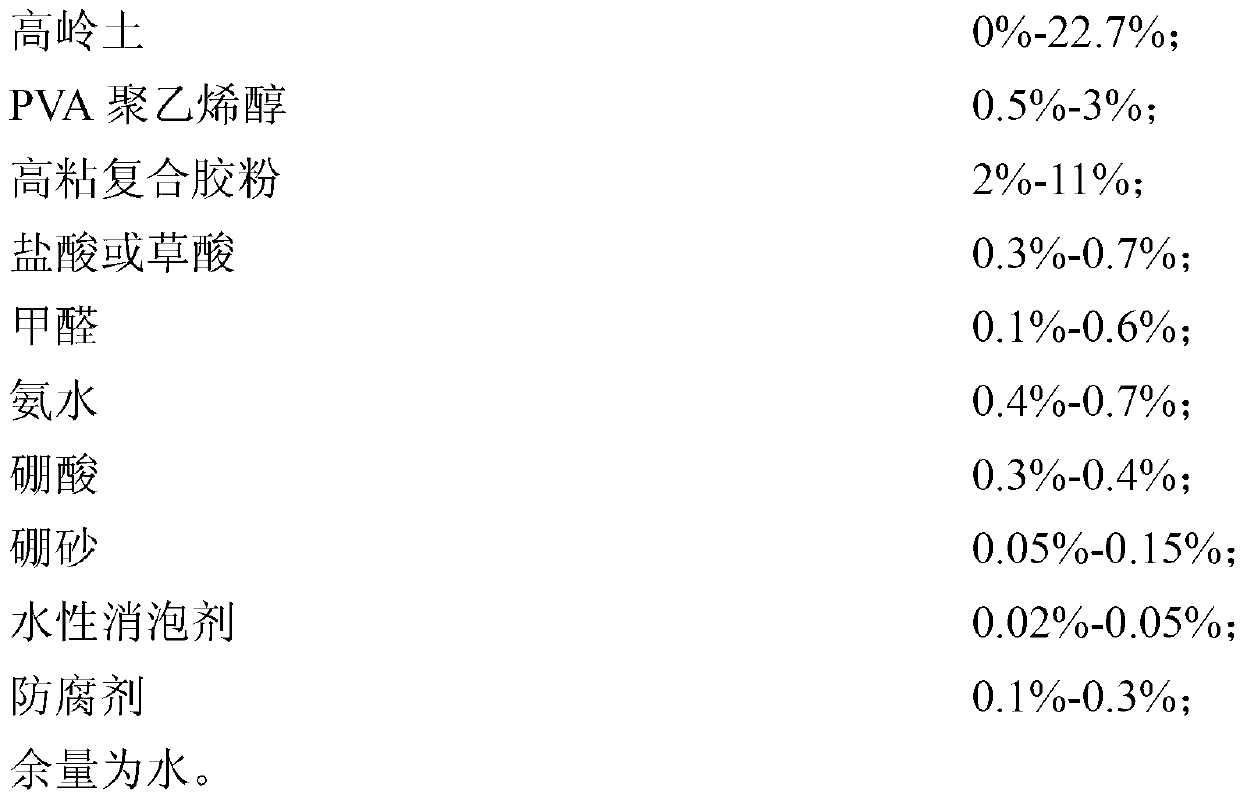

[0039] Prepare 1 ton of adhesive, the amount of each component is as follows:

[0040] components

Embodiment 2

[0042] Prepare 1 ton of adhesive, the amount of each component is as follows:

[0043] components

Embodiment 3

[0045] Prepare 1 ton of adhesive, the amount of each component is as follows:

[0046] components

Weight (kg)

Kaolin (paste, 65% solids)

227

30

High Viscosity Compound Rubber Powder

110

7

6

7

4

1.5

ethylene glycol

1.5

0.5

Casson

3

[0047] The balance is water

[0048] The adhesive of embodiment 1 can be prepared according to the following steps:

[0049] 1) Mix the cross-linking agent with warm water at about 50°C at a ratio of 1:15, and set aside;

[0050] 2) water is injected in the reactor, heating;

[0051] 3) At 30°C, add PVA polyvinyl alcohol and 0.15kg water-based defoamer to prevent overflow;

[0052] 4) When the temperature reaches 90°C, stop heating and keep warm for 45 minutes;

[0053] 5) Continuously add hydrochl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com