Non-aqueous electrolyte used in sodium ion battery, sodium ion battery and application

A sodium ion battery and electrolyte salt technology, applied in the field of electrolyte sodium salt, can solve the problems of poor cycle performance and low battery coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example illustrates the formulation of NaFSI / EC:DMC electrolyte and its application in sodium-ion batteries using hard carbon as the working electrode.

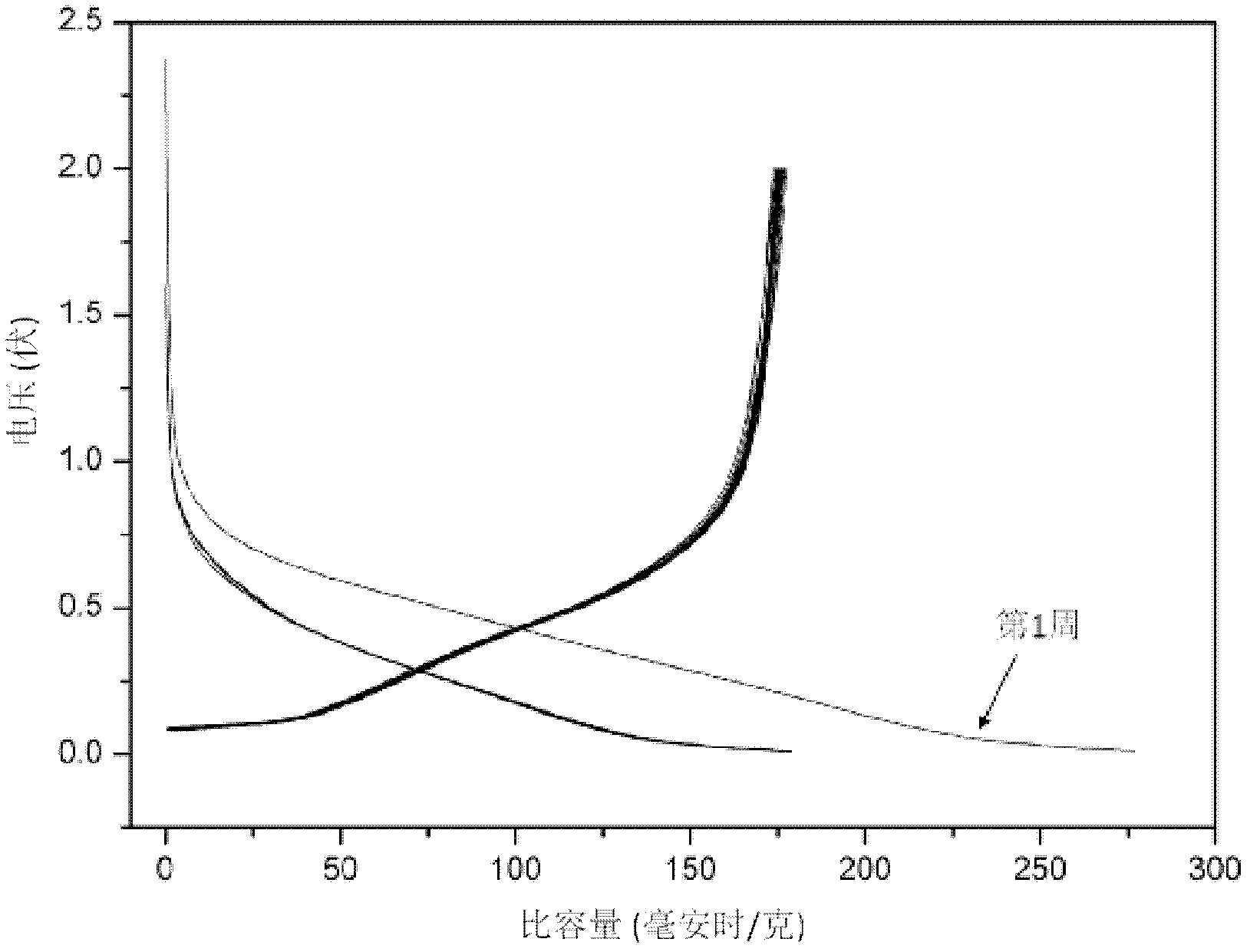

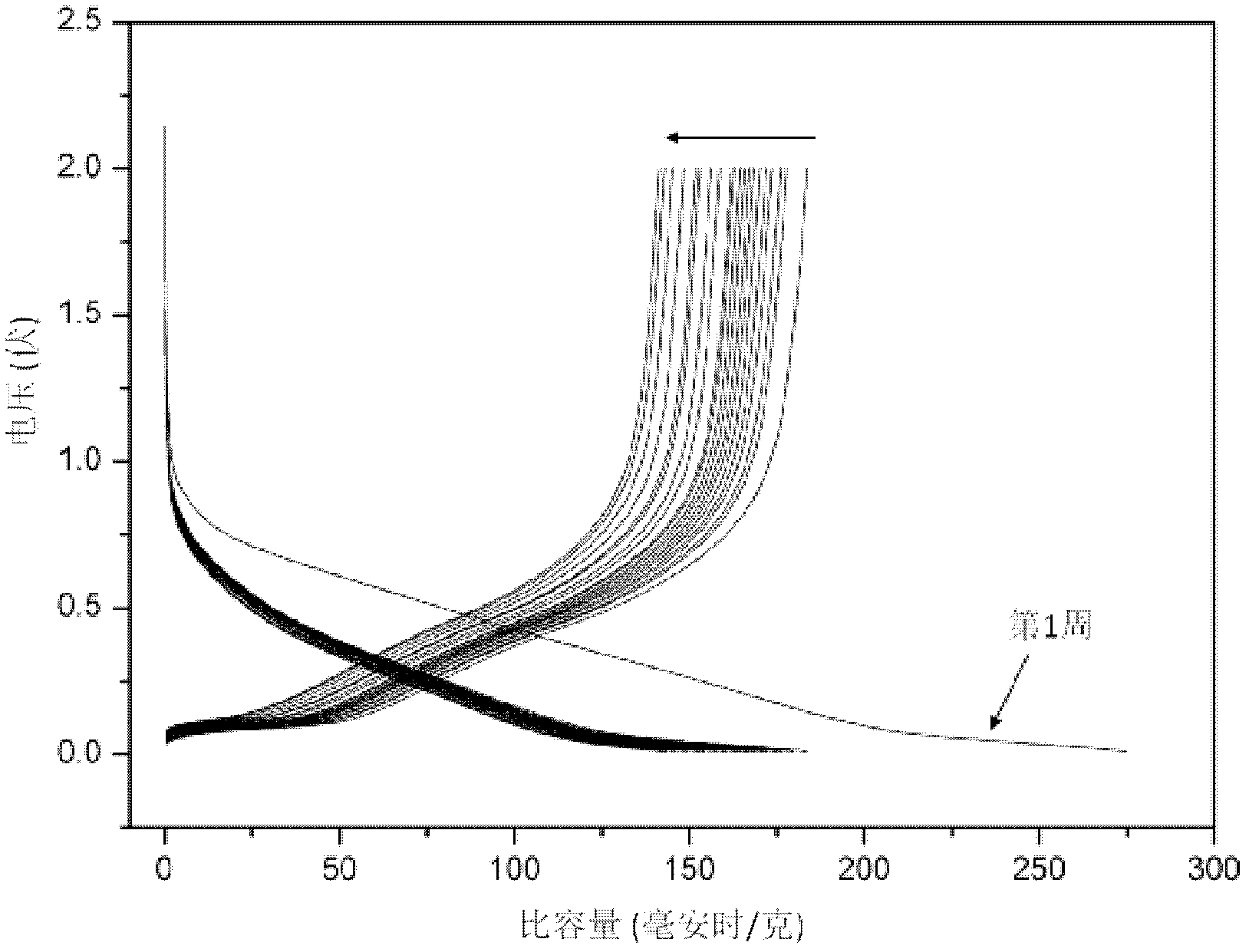

[0032] Weigh NaFSI according to the concentration of 1M, measure organic solvent EC and DMC (volume ratio is 2:3), add molecular sieve to remove water after stirring and dissolving, and obtain the required electrolyte when the water concentration drops below 10ppm. The battery assembly and testing process is as follows: a metal sodium sheet is used as the counter electrode, the active material hard carbon electrode sheet is used as the working electrode, a glass fiber separator is added, and the NaFSI / EC:DMC electrolyte is added to assemble a CR2032 button battery. The test was carried out in constant current charge-discharge mode, the discharge cut-off voltage was 0.01V, the charge cut-off voltage was 2V, and the current density was 25mA / g. See test results figure 1 .figure 1 It is the charge-discharge curve of ...

Embodiment 2

[0037] This example illustrates the formulation of NaFSI / PC electrolyte and the use of Na 2 Ti 3 O 7 Application in sodium-ion batteries when it is the working electrode.

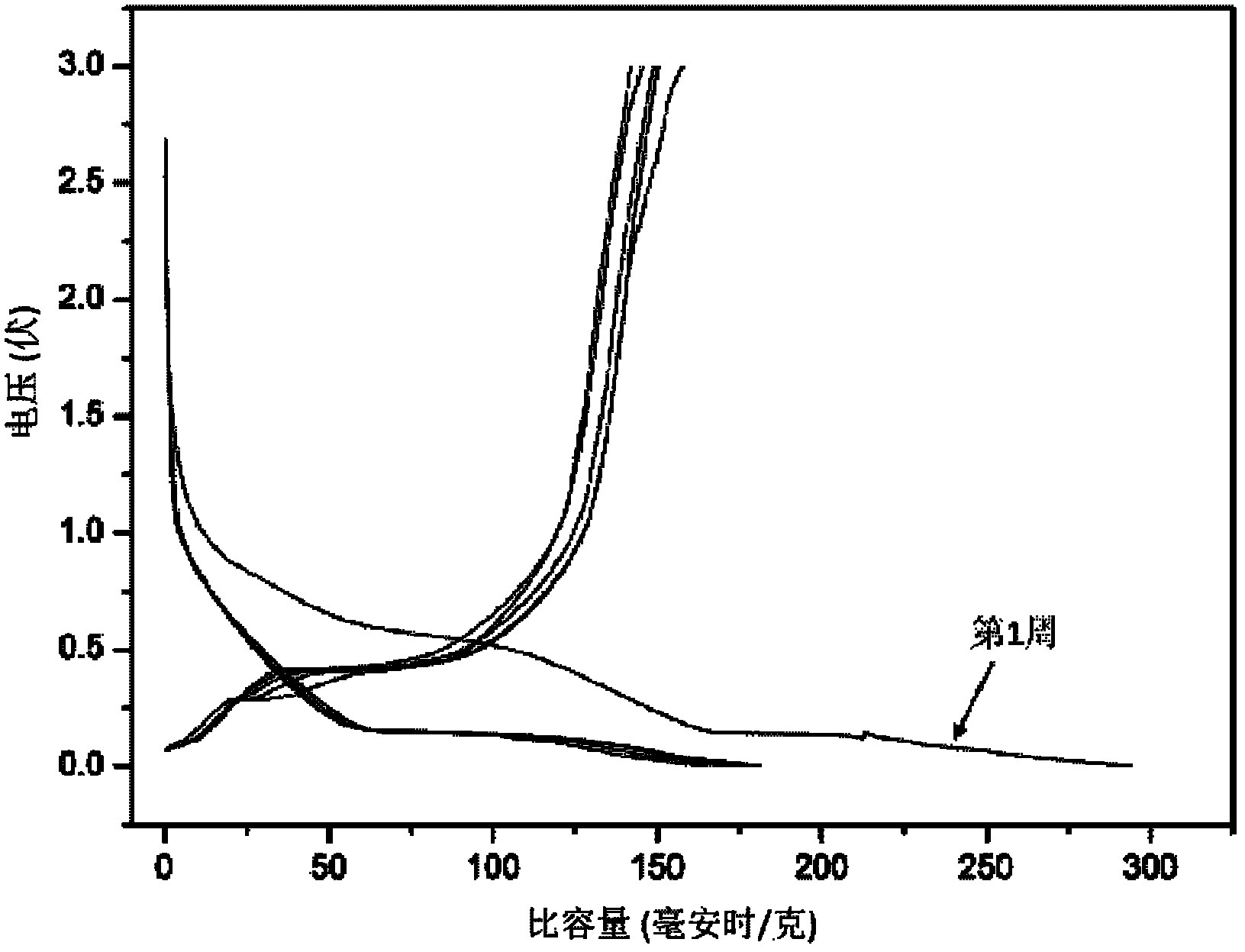

[0038] Weigh NaFSI according to the concentration of 1M, measure the organic solvent PC, add molecular sieve to remove water after stirring and dissolving, and obtain the required electrolyte when the water concentration drops below 10ppm. The battery assembly and testing process is as follows: the metal sodium sheet is used as the counter electrode, and the active material Na is used as the counter electrode. 2 Ti 3 O 7 The pole piece is the working electrode, the glass fiber separator is added with the NaFSI / PC electrolyte, and the CR2032 button cell is assembled. The test was carried out in constant current charge-discharge mode, the discharge cut-off voltage was 0.01V, the charge cut-off voltage was 3V, and the current density was 10mA / g. See test results image 3 . image 3 is the charge-discha...

Embodiment 3

[0043] This example illustrates the formulation of NaFSI / EC:DEC electrolyte and the use of Li 4 Ti 5 O 12 Application in sodium-ion batteries when it is the working electrode.

[0044] Weigh NaFSI according to the concentration of 1M, measure organic solvent EC and DEC (volume ratio is 2:3), add molecular sieve to remove water after stirring and dissolving, and obtain the required electrolyte when the water concentration drops below 10ppm. The battery assembly and testing process is as follows: the metal sodium sheet is used as the counter electrode, and the active material Li 4 Ti 5 O 12 The pole piece is the working electrode, the glass fiber separator is added with the NaFSI / EC:DEC electrolyte, and the CR2032 button cell is assembled. The constant current charge-discharge mode was used for testing, the discharge cut-off voltage was 0.5V, the charge cut-off voltage was 3V, and the current density was 17.5mA / g. See test results Figure 5 . Figure 5 It is the charge-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com